Compression of a standard new engine

prior

to

Spec

P at

about 300rpm is approximately 300 - 350

psi.

Beginning

Spec

P, compression is about 350 - 400 psi.

Compression reading

will

deviate considerably

from

the

above readings

because

of differences in cranking

speed,

altitude

and ambient temperature conditions. Therefore the

specification

is given

only

as a guide. The

best

indi-

cation

of leakage is a compression increase when oil is

added to the cylinder.

DISASSEMBLY

1.

Remove the decompression solenoid.

2..

Remove the rocker box cover,

fuel

nozzle and connect-

ing oil

lines to the cylinderhead.

3. Remove the intake and exhaust

manifold.

4.

Remove the cap screws

holding

the cylinder head to the

cylinder

block.

5. Remove the head. If it sticks, rap it sharply

with

a soft

hammer. Do not use a pry.

6. Remove the rocker arms and push rods.

7. Using a valve spring compressor, disassemble the valve

assemblies.

REPAIR

Thoroughly

clean all components of the cylinder head as-

sembly.

Remove all the carbon deposits

from

the intake and

exhaust ports and clean all gasket surfaces.

Valves:

Remove all carbon and check each valve for burning,

pitting

or warped stem. Valves that are

slightly

pitted

or

burned,

refinish

on an accurate valve grinder. Refinish

intake

valves to a 42° angle and exhaust valves to a 45°

angle. But, if they are badly

pitted,

or

will

have a

thin

edge

when refacing, replace them.

Check refinished valves toi a

tight

seat

to the valve

seat

with

an air

pressure

type testing

tool

or by applying Prussian

Blue

on the valve face and rotating it against the

seat.

Valve

Guides: Check valve guide to valve clearance, see

Table of Clearances. If the proper

clearances

cannot be

obtained

by replacing the valves, replace the valve guides.

Drive

the old valve guides

into

the valve chambers.

Drive

new guides in

until

they protrude 11/32"

from

the rocker box

side of the head. Ream the new valve guide to obtain the

proper clearance.

Volve

Seats:

if the valve

seats

are

pitted,

refinish

them.

Using

conventional

seat

grinding

equipment, reface each

seat

to a 45° angle and a

seat

width

of 3/64 to

1/16".

You

should

be able to reface each

seat

several times before it

becomes

necessary

to replace it.

If,

however, the valve

seats

are loose or cannot be refaced,

replace them.

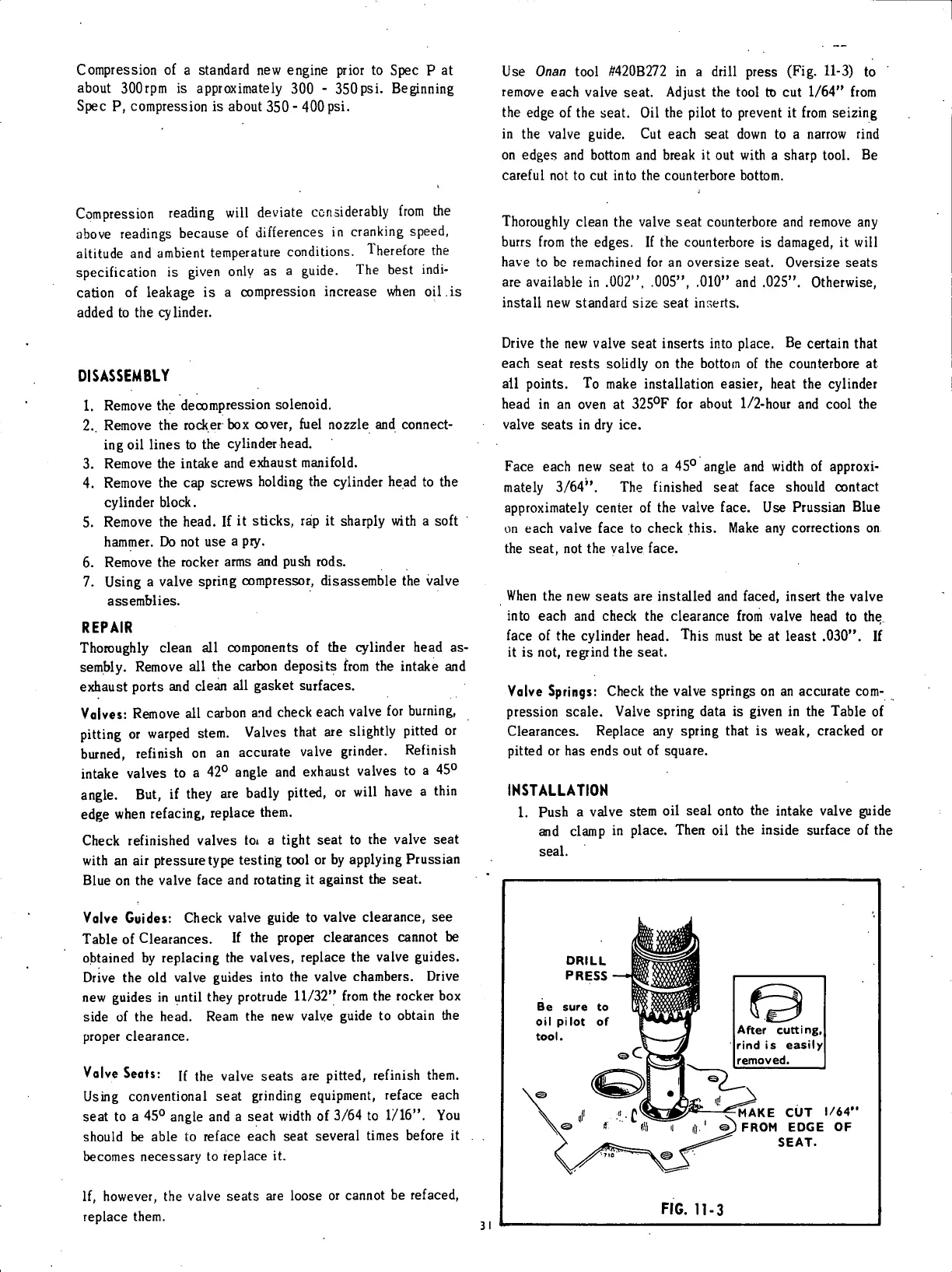

Use Onan

tool

#4208272 in a

drill

press

(Fig. 11-3) to

remove each valve

seat.

Adjust

the

tool

to cut 1/64"

from

the

edge

of the

seat.

Oil the

pilot

to prevent it

from

seizing

in

the valve guide. Cut each

seat

down to a narrow

rind

on

edges

and bottom and break it out

with

a

sharp

tool.

Be

careful

not to cut

into

the counterbore bottom.

Thoroughly

clean the valve

seat

counterbore and remove any

burrs

from

the

edges.

If the counterbore is damaged, it

will

have to be remachined for an oversize

seat.

Oversize

seats

are available in .002", .005", .010" and .025". Otherwise,

install

new standard size

seat

inserts.

Drive

the new valve

seat

inserts

into

place. Be certain that

each

seat

rests

solidly

on the bottom of the counterbore at

all

points. To make installation

easier,

heat

the cylinder

head in an oven at 325

0

F for about 1/2-hour and

cool

the

valve

seats

in dry ice.

Face

each new

seat

to a 45° angle and

width

of approxi-

mately

3/64". The finished

seat

face should contact

approximately

center of the valve face. Use Prussian Blue

on

each valve face to check this. Make any corrections on

the

seat,

not the valve face.

When

the new

seats

are installed and faced, insert the valve

into

each and check the clearance

from

valve head to the.

face of the cylinder head. This must be at least .030". If

it

is not, regrind the

seat.

Valve

Springs: Check the valve springs on an accurate com-

pression scale.

Valve

spring data is given in the Table of

Clearances. Replace any spring that is weak, cracked or

pitted

or has

ends

out of

square.

INSTALLATION

1.

Push a valve stem oil seal onto the intake valve guide

and clamp in place. Then oil the inside surface of the

seal.

31

DRILL

PRESS

Be

sure

to

oil

pilot

of

tool.

After

cutting,

rind

is easily

MAKE

CUT 1/64"

FROM

EDGE

OF

SEAT.

FIG.

11-3

Loading...

Loading...