Important: Units built beiore June 1962

had no

valve

seals.

2.

OU the stem of

each

valve

lightly

and insert

each

in

its

own guide.

3. Check

each

valve for a

tight

seat

with

an air

pressure

type

tester

If a

tester

is not available, make pencil

marks at intervals on the valve face and

observe

if the

marks rub off

uniformly

when the valve is rotated part

of

a turn in the

seat.

If the

seat

is not tight, regrind

the valves.

4.

Using a valve spring

compressor,

compress

each

valve

spring

and insert the valve spring retainer, and retainer

locks.

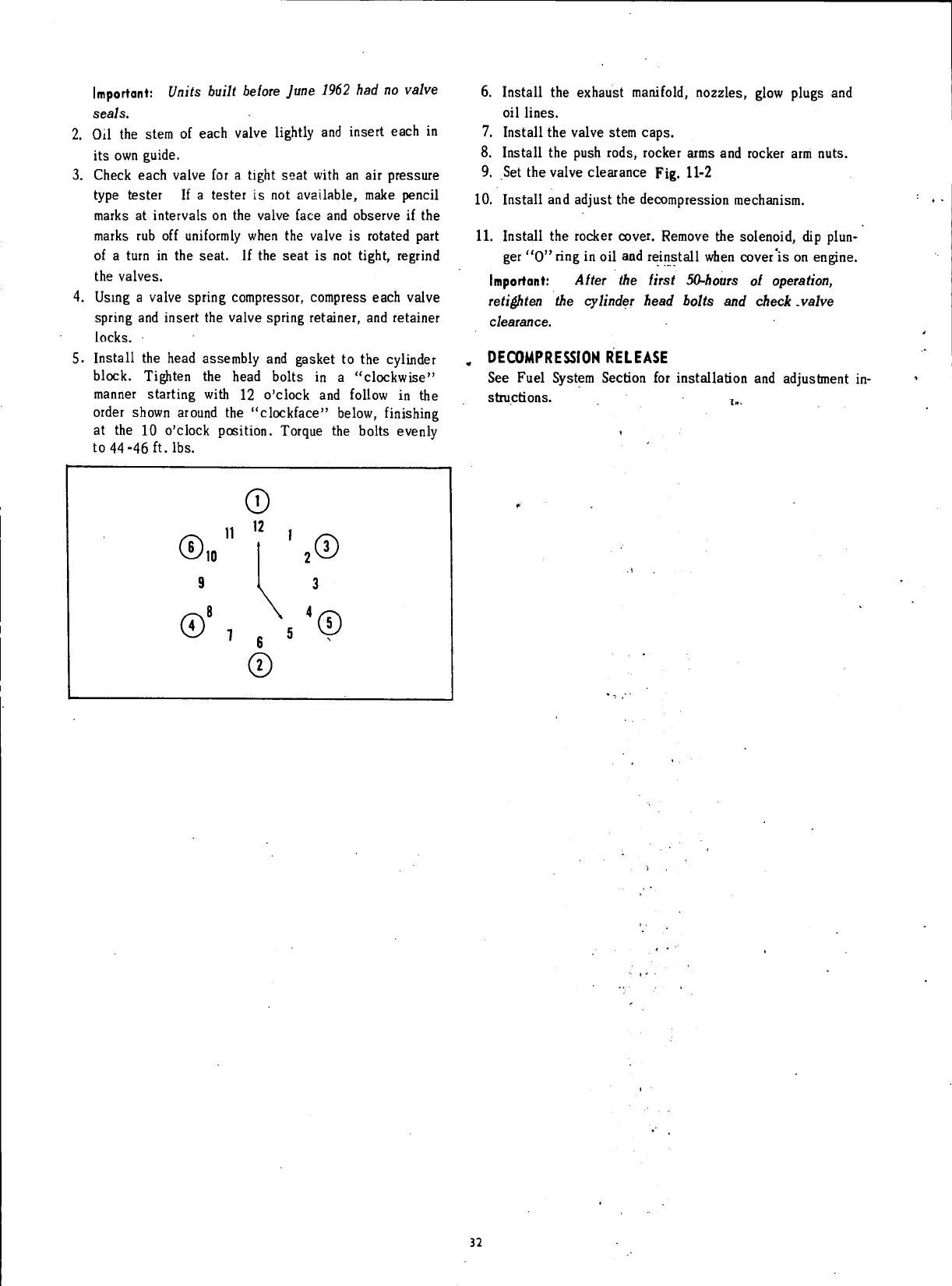

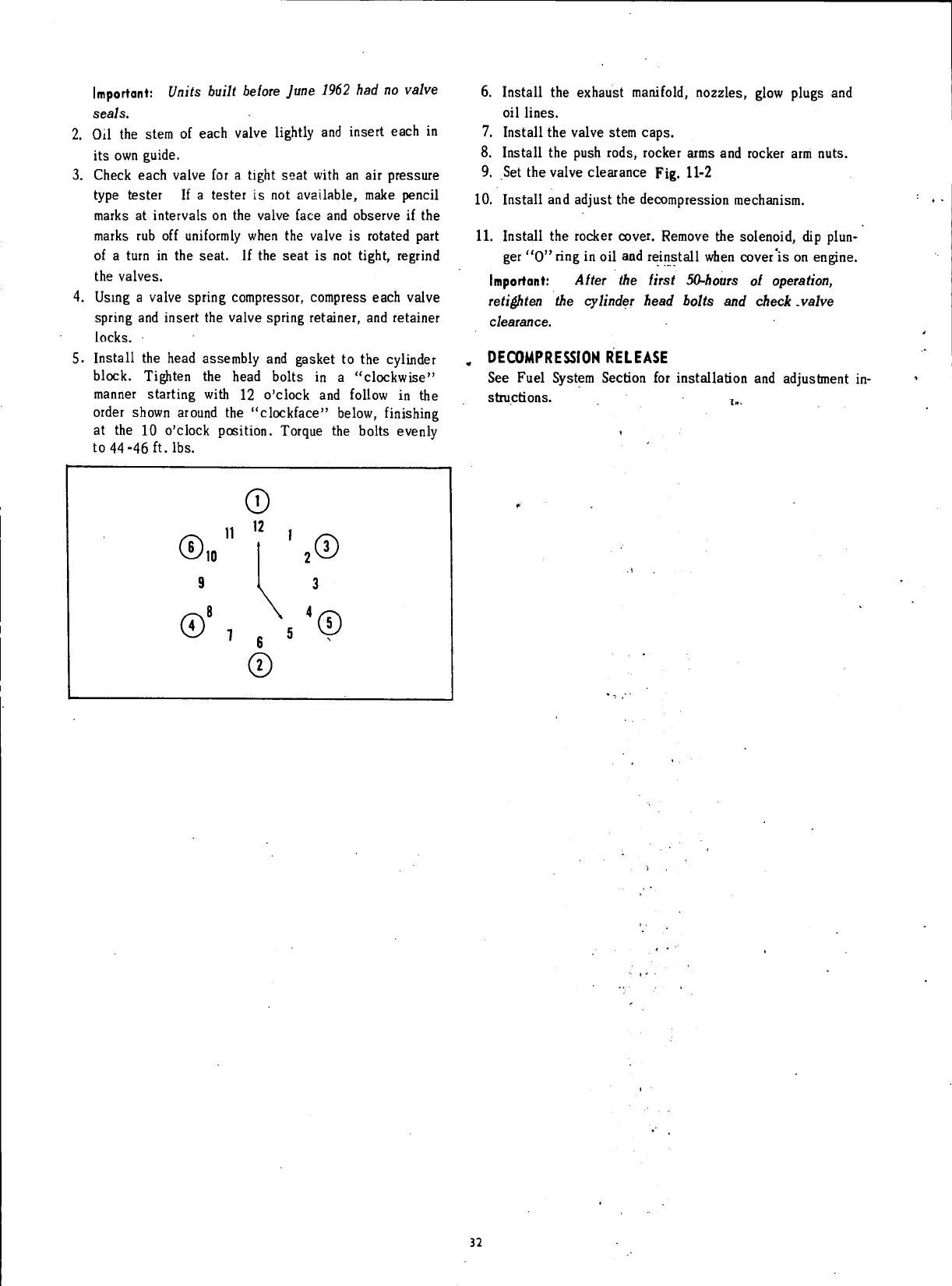

5. Install the

head

assembly and

gasket

to the cylinder

block.

Tighten the

head

bolts in a "clockwise"

manner starting

with

12 o'clock and

follow

in the

order shown around the "clockface" below,

finishing

at the 10 o'clock position. Torque the bolts evenly

to

44-46

ft.

lbs.

6. Install the

exhaust

manifold, nozzles, glow plugs and

oil

lines.

7. Install the valve stem

caps.

8. Install the push rods, rocker

arms

and rocker arm nuts.

9. Set the valve

clearance

Fig. 11-2

10.

Install and adjust the decompression mechanism.

11.

Install the rocker cover. Remove the solenoid, dip plun-

ger "0"

ring

in

oil

and reinstall when cover is on engine.

Important: Aiter

the

first 50-hours

ol

operation,

retighten

the

cylinder head bolts

and

check .valve

clearance.

,

DECOMPRESSION

RELEASE

See Fuel System Section for installation and adjustment in-

structions.

32

Loading...

Loading...