PISTONS,

RINGS,

RODS,

This

engine

uses

a cam ground aluminum piston tapered and

fitted with

three compression rings and an oil

control

ring.

A full

floating

piston pin connects the piston to its' con-

necting

rod. The pin is held in place

with

a

snap

ring

at

each end.

The,

lower

end of the connecting rod contains

half

shell,

precision bearings and the upper end, semi-finished

bushings. • ^ -

Important: Some engines

are

fitted with

a .005"

oversize

piston

at

the

factory.

These engines are

marked with

an

E

following

the

engine serial

number.

REMOVAL

AND

DISASSEMBLY

1.

Drain

the crankcase

oil

and remove the

oil

base.

2.

Remove the cylinder head.

3. Remove the cap

from

the connecting rod and push the

assembly through the top of the cylinder bore. Replace

the cap and bearing inserts in the assembly.

4.

Using a

ring

expander, remove the rings

.

from

the

piston.

5. Remove the two retaining rings and push the piston pin

from

the piston.

CYLINDERS

The cylinder

wall

should be free of

scratches,

pitting

and

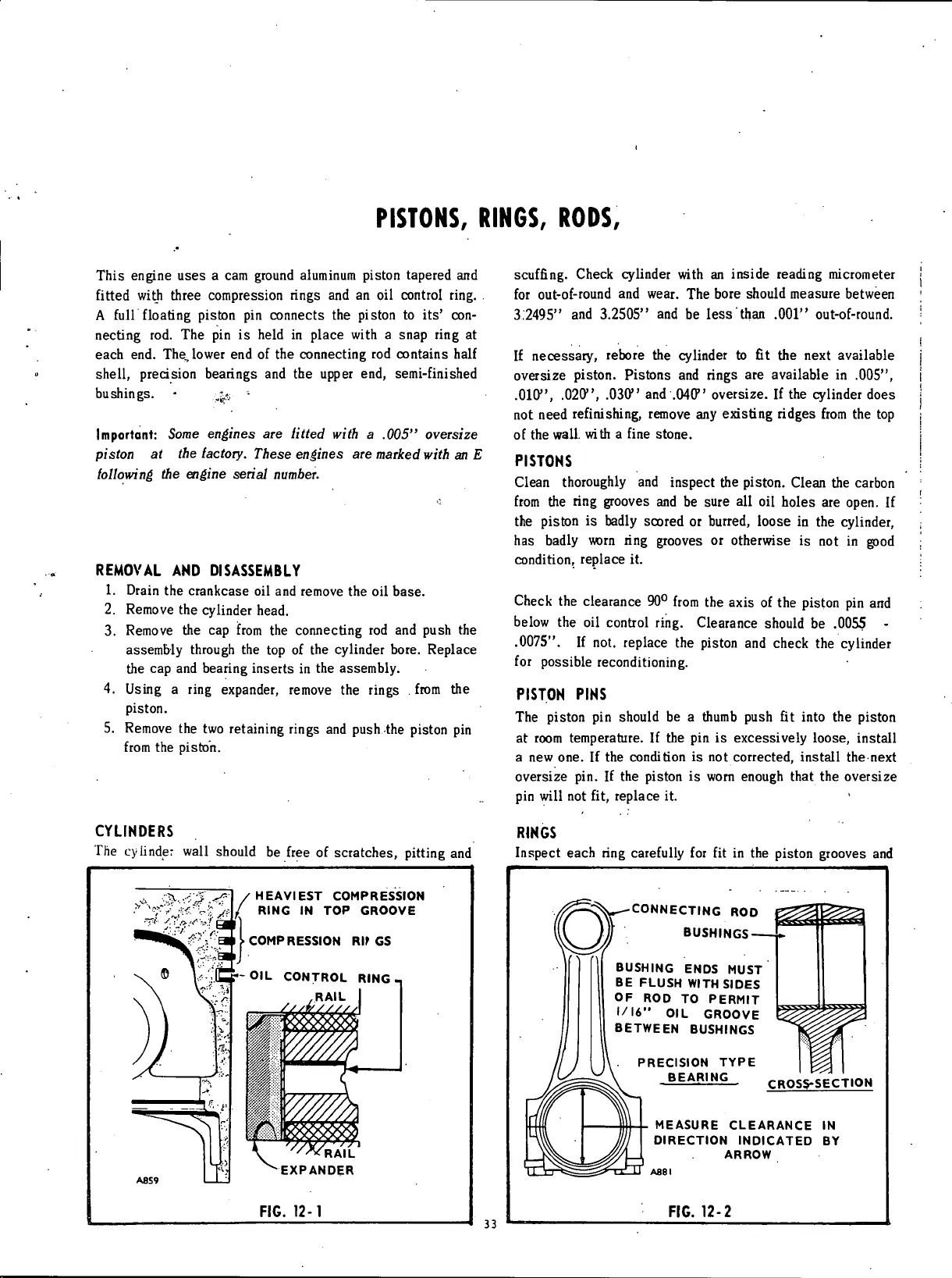

COMPRESSION

RU GS

*-

OIL

CONTROL RING

RAIL

3^

HEAVIEST COMPRESSION

RING

IN TOP

GROOVE

•RAIL

•EXPANDER

FIG.

12-1

scuffing.

Check cylinder

with

an inside reading micrometer

for

out-of-round and wear. The bore should

measure

between

3:2495" and 3.2505" and be

less

than .001" out-of-round.

If

necessary,

rebore the cylinder to fit the next available

oversize piston. Pistons and rings are available in .005",

.010",

.020", .030" and .040" oversize. If the cylinder

does

not

need

refinishing,

remove any existing ridges

from

the top

of

the

wall,

with

a

fine

stone.

PISTONS

Clean

thoroughly and inspect the piston. Clean the carbon

from

the

ring

grooves and be

sure

all oil holes are open. If

the piston is badly scored or burred, loose in the cylinder,

has badly

\rorn

ring

grooves or otherwise is not in good

condition,

replace it.

Check the clearance 90°

from

the axis of the piston pin and

below

the oil

control

ring.

Clearance should be .0055 -

.0075".

If not. replace the piston and check the cylinder

for

possible

reconditioning.

PISTON PINS

The piston pin should be a thumb push fit

into

the piston

at room temperature. If the pin is excessively loose,

install

a new one. If the

condition

is not corrected,

install

the next

oversize pin. If the piston is wom enough that the oversize

pin

will

not

fit,

replace it.

RINGS

Inspect each

ring

carefully

for fit in the piston grooves and

33

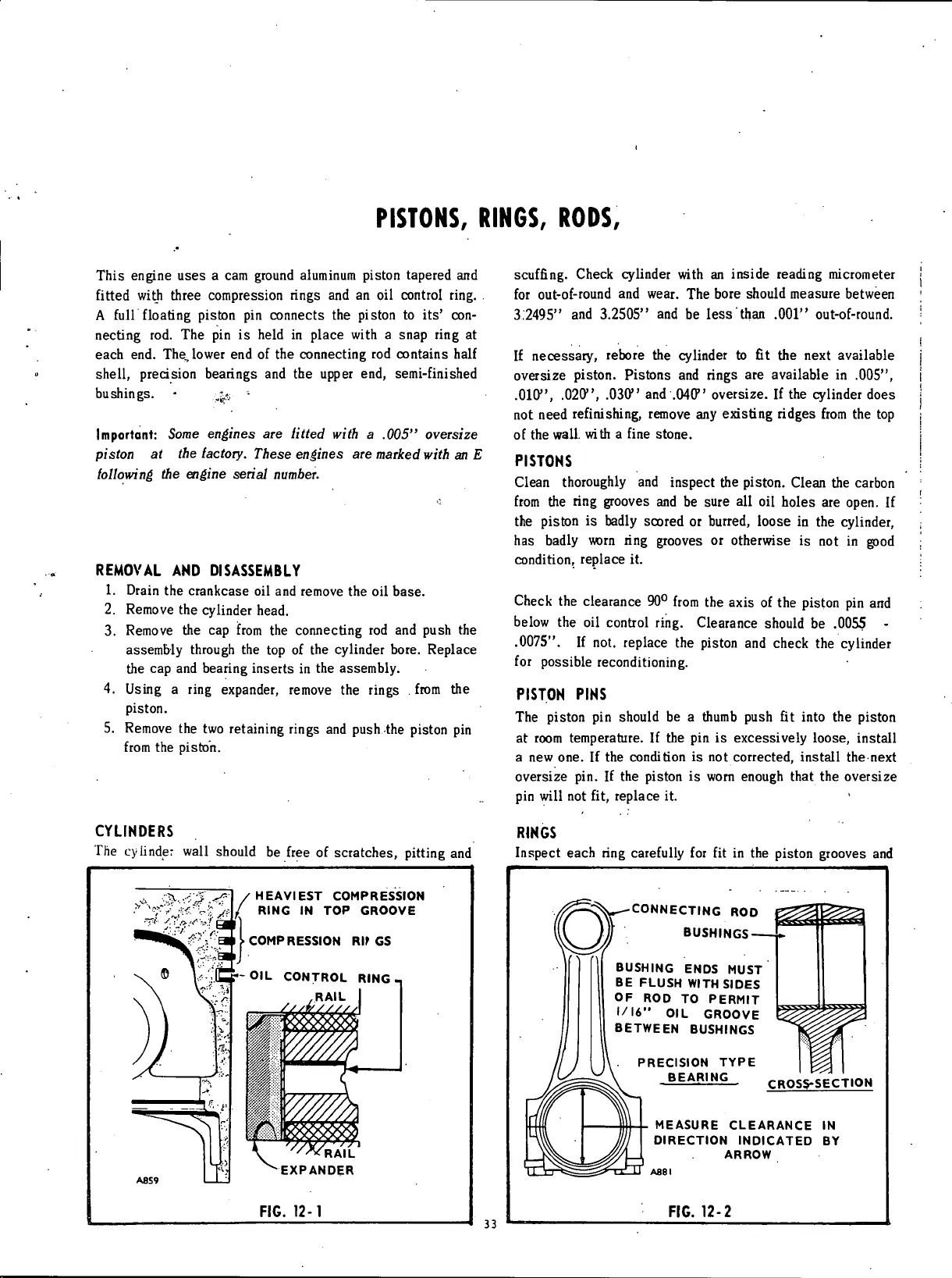

CONNECTING

ROD

BUSHINGS-

BUSHING ENDS MUST

BE FLUSH WITH SIDES

OF

ROD TO

PERMIT

1/16"

OIL

GROOVE

BETWEEN BUSHINGS

PRECISION TYPE

BEARING

CROSS-SECTION

MEASURE CLEARANCE

IN

DIRECTION INDICATED

BY

ARROW

AS8I

FIG.

12-2

Loading...

Loading...