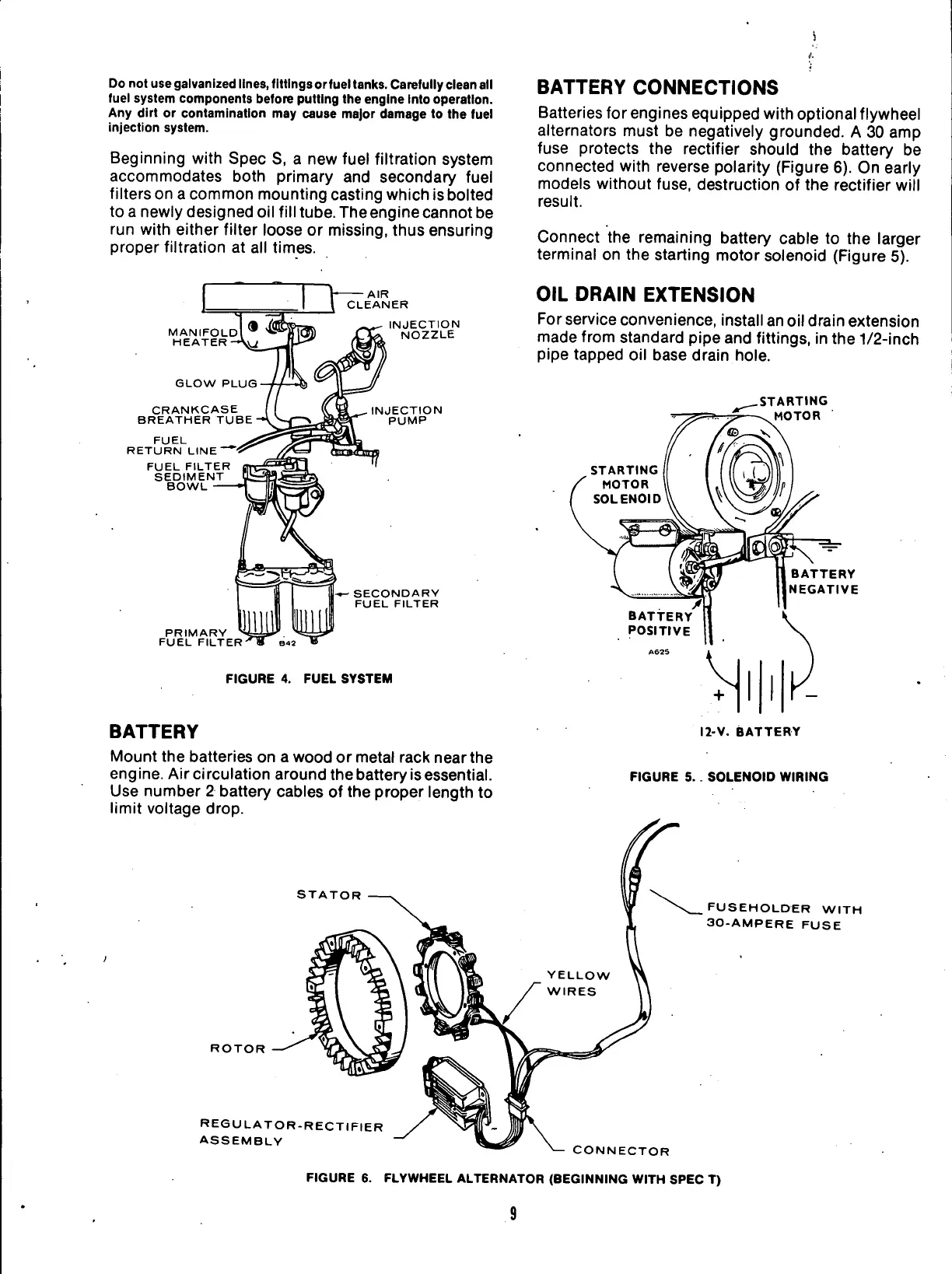

Do not use galvanized lines, fittings orfuel tanks. Carefully clean all

fuel system components before putting the engine into operation.

Any dirt or contamination may cause major damage to the fuel

injection system.

Beginning with Spec S, a new fuel filtration system

accommodates both primary and secondary fuel

filters on a common mounting casting which is bolted

to a newly designed oil fill

tube.

Theengine cannot be

run with either filter loose or missing, thus ensuring

proper filtration at all times.

AIR

CLEANER

MANIFOLD

HEATER

SLOW PLUG

CRANKCASE

BREATHER TUBE

FUEL

RETURN LINE

FUEL FILTER

SEDIMENT

BOWL

PRIMARY

FUEL FILTER

INJECTION

NOZZLE

INJECTION

PUMP

SECONDARY

FUEL FILTER

FIGURE 4. FUEL SYSTEM

BATTERY

Mount the batteries on a wood or metal rack nearthe

engine. Air circulation around the battery

is

essential.

Use number 2 battery cables of the proper length to

limit voltage drop.

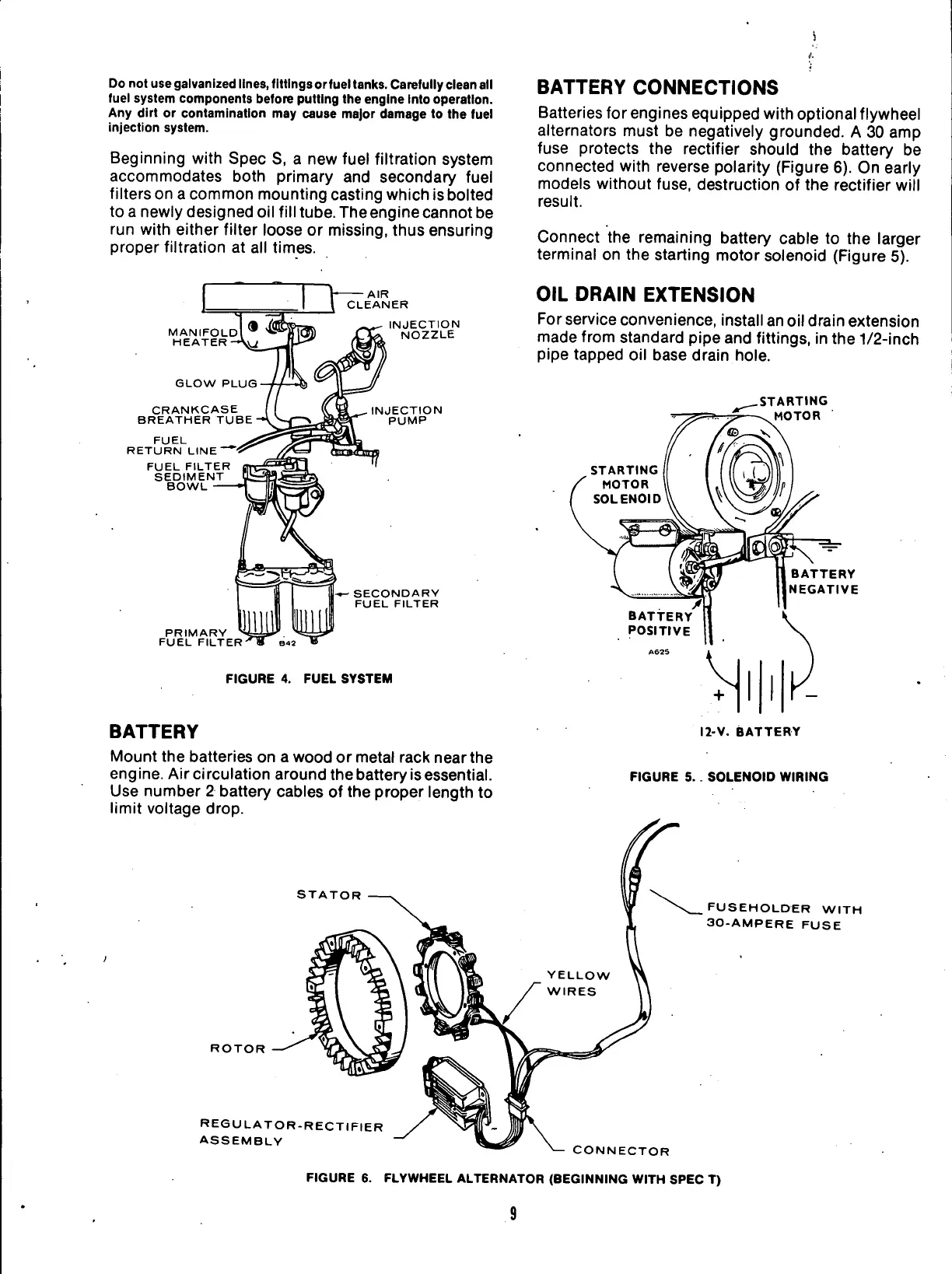

STATOR

BATTERY

CONNECTIONS

Batteries for engines equipped with optional flywheel

alternators must be negatively grounded. A 30 amp

fuse protects the rectifier should the battery be

connected with reverse polarity (Figure 6). On early

models without fuse, destruction of the rectifier will

result.

Connect the remaining battery cable to the larger

terminal on the starting motor solenoid (Figure 5).

OIL

DRAIN

EXTENSION

For service convenience, install

an

oil drain extension

made from standard pipe and fittings, in the

1/2-inch

pipe tapped oil base drain hole.

STARTING

MOTOR

BATTERY

NEGATIVE

I2-V. BATTERY

FIGURE 5.. SOLENOID WIRING

FUSEHOLDER WITH

30-AMPERE FUSE

ROTOR

REGULATOR-RECTIFIER

ASSEMBLY

CONNECTOR

FIGURE 6. FLYWHEEL ALTERNATOR (BEGINNING WITH SPEC T)

9

Loading...

Loading...