Before engine is put in operation, check all components for as required. The engine should be kept free of dust,

dirt,

mechanical security. Ifany abnormal condition, defective and spilled oil or

fuel.

Be

sure

proper operating procedure

part, or operating

difficulty

is detected, repair or service is

followed.

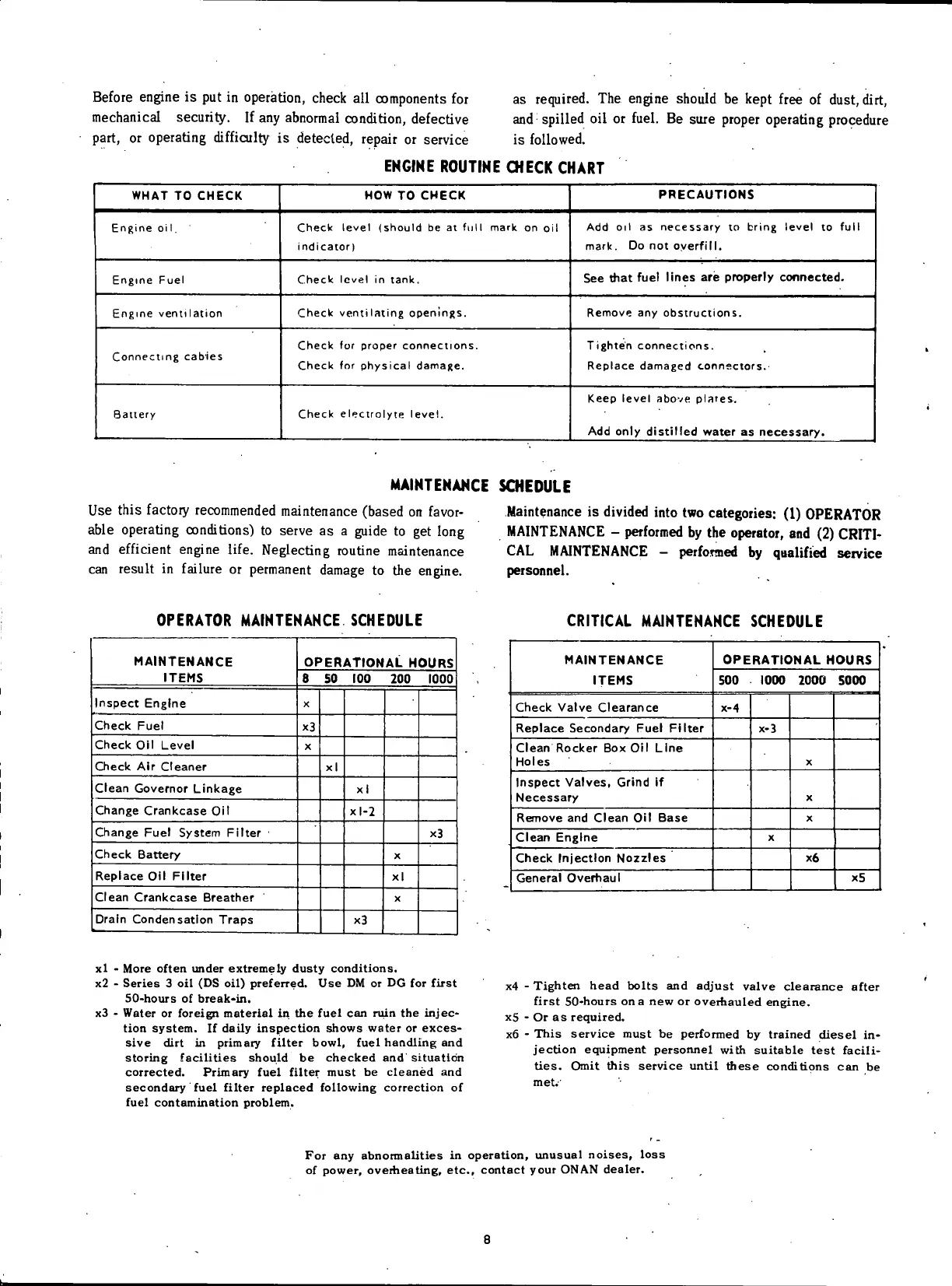

EHGINE

ROUTINE

CHECK

CHART

WHAT

TO

CHECK

HOW

TO

CHECK

PRECAUTIONS

Engine

oil.'

Check level (should

be at

full mark

on oil

indicator)

Add

oil as

necessary

to

bring level

to

full

mark.

Do not

overfill.

Engine Fuel

Check level

in

tank.

See that fuel lines

are

properly connected.

Engine ventilation

Check ventilating openings. Remove

any

obstructions.

Connecting cables

Check

for

proper connections.

Check

for

physical damage.

Tighten connections.

Replace damaged connectors.

Battery

Check electrolyte level.

Keep level above plates.

Add only distilled water

as

necessary.

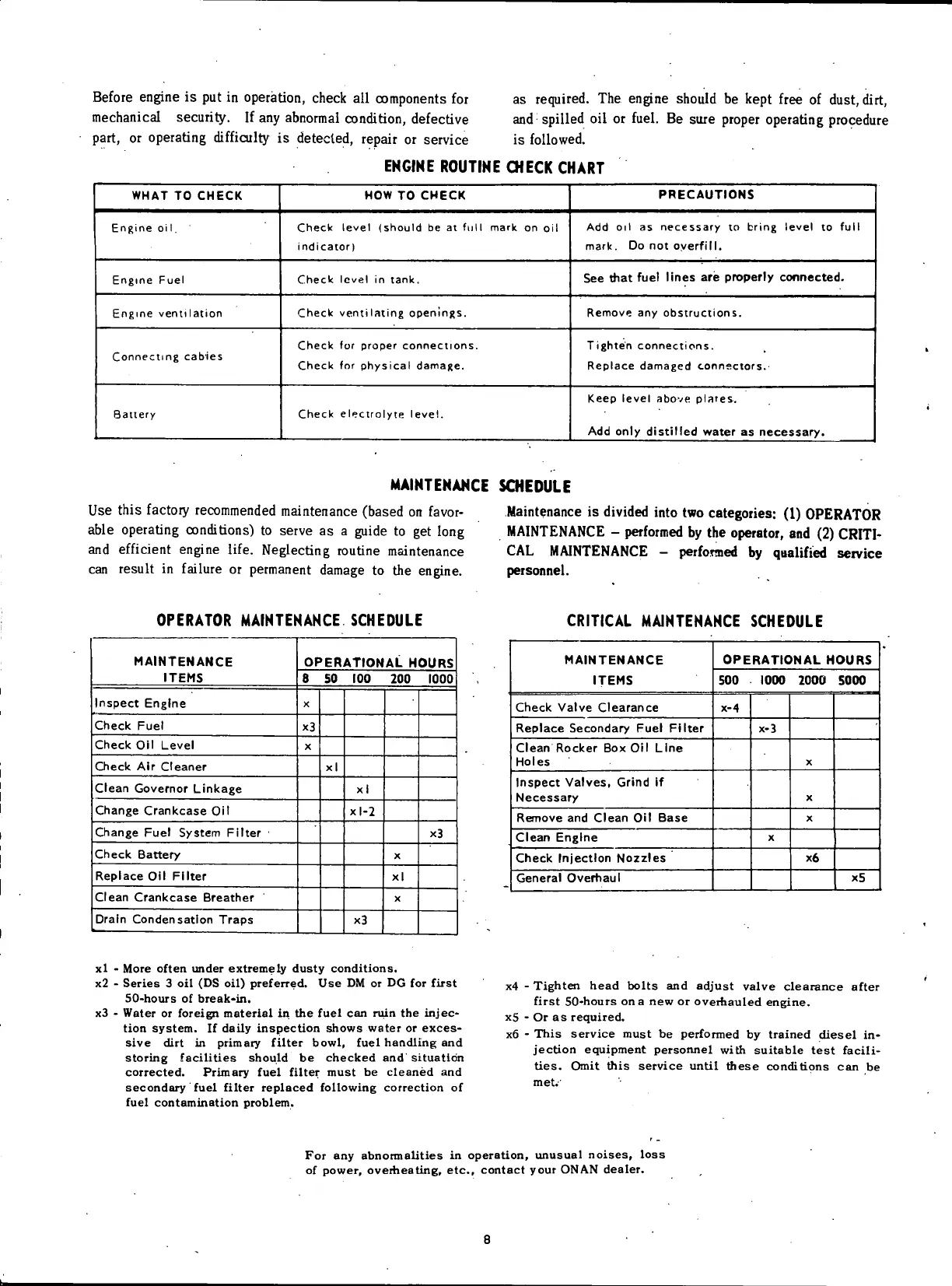

MAINTENANCE

SCHEDULE

Use this factory recommended maintenance

(based

on favor-

able operating conditions) to

serve

as a guide to get long

and efficient engine

life.

Neglecting routine maintenance

can result in failure or permanent

damage

to the engine.

Maintenance is divided

into

two categories: (1)

OPERATOR

MAINTENANCE

- performed by the operator, and (2)

CRITI-

CAL

MAINTENANCE

- performed by qHalified service

personnel.

OPERATOR

MAINTENANCE

SCHEDULE

CRITICAL

MAINTENANCE

SCHEDULE

MAINTENANCE

ITEMS

OPERATIONAL HOURS

MAINTENANCE

ITEMS

8

SO 100 200 1000

Inspect Engine

X

Check Fuel

x3

Check

Oil

Level

X

Check

Air

Cleaner

xl

Clean Governor Linkage

xl

Change Crankcase

Oil

xl-2

Change Fuel System Filter

x3

Check Battery

X

Replace

Oil

Filter xl

Clean Crankcase Breather X

Drain Condensation Traps

x3

MAINTENANCE

ITEMS

OPERATIONAL HOURS

MAINTENANCE

ITEMS 500

1000

2000 SOOO

Check Valve Clearance

x-4

Replace Secondary Fuel Filter

x-3

Clean Rocker

Box Oil

Line

Holes

X

Inspect Valves, Grind

if

Necessary

X

Remove

and

Clean

Oil

Base

X

Clean Engine

X

Check Injection Nozzles x6

General Overhaul x5

xl

- More often under extremely dusty conditions.

x2

-

Series

3 oil (DS oil) preferred. Use DM or DG for

first

50-hours of break-in.

x3 - Water or foreign inaterial in the

fuel

can

ruin

the injec-

tion

system. If daily inspection shows water or

exces-

sive

dirt

in primary

filter bowl, fuel

handling and

storing

facilities should be checked and situation

corrected. Primary

fuel filter

must be cleaned and

secondary'

fuel filter

replaced

following

correction of

fuel

contamination problem.

x4

- Tighten

head

bolts and adjust valve

clearance

after

first

50-hours ona new or overtiauled engine.

x5 - Or as required.

x6

- This service must be performed by trained diesel in-

jection

equipment personnel

with

suitable

test

facili-

ties.

Omit

this service

until

these

conditions can be

met.

For any abnormalities in operation, unusual

noises,

loss

of

power, overheating, etc., contact your

ONAN

dealer.

Loading...

Loading...