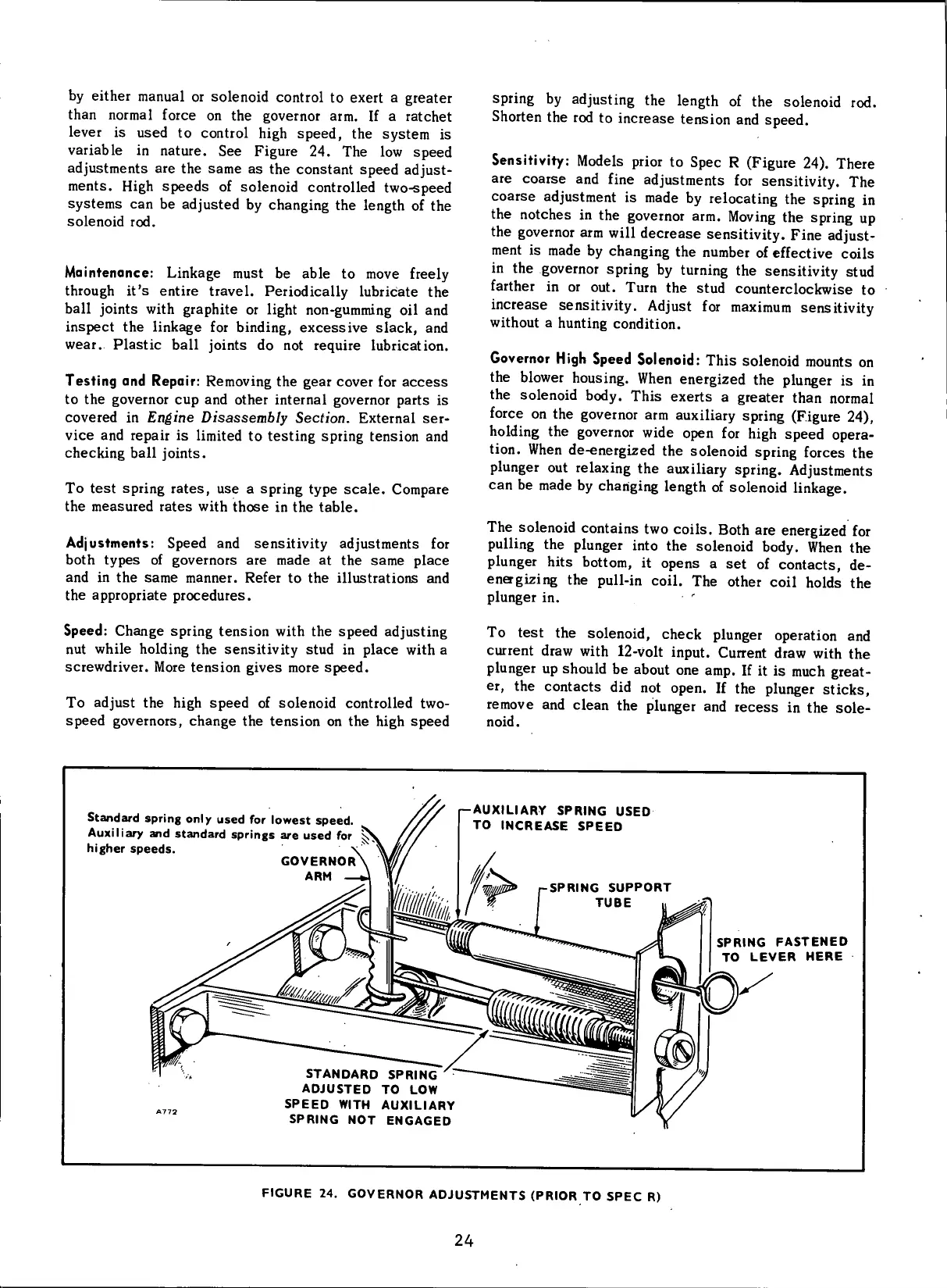

by

either manual or solenoid control to exert a

greater

than normal force on the governor arm. If a ratchet

lever is

used

to control high

speed,

the system is

variable in nature. See Figure 24. The low

speed

adjustments are the

same

as the constant

speed

adjust-

ments.

High

speeds

of solenoid controlled two-speed

systems

can be adjusted by changing the length of the

solenoid rod.

Maintenance: Linkage must be able to move freely

through

it's entire travel. Periodically lubricate the

ball

joints

with

graphite or

light

non-gumming oil and

inspect the linkage for binding,

excessive

slack, and

wear.. Plastic

ball

joints do not require lubrication.

Testing and Repair: Removing the

gear

cover for

access

to

the governor cup and other internal governor

parts

is

covered in Engine Disassembly Section. External

ser-

vice

and repair is

limited

to testing spring tension and

checking

ball

joints.

To

test

spring

rates,

use a spring type

scale.

Compare

the

measured

rates

with

those

in the table.

Adjustments:

Speed

and sensitivity adjustments for

both

types of governors are

made

at the

same

place

and in the

same

manner. Refer to the illustrations and

the appropriate procedures.

Speed:

Change

spring tension

with

the

speed

adjusting

nut

while

holding the sensitivity stud in place

with

a

screwdriver. More tension gives more

speed.

To

adjust the high

speed

of solenoid controlled two-

speed

governors,

change

the tension on the high

speed

spring

by adjusting the length of the solenoid rod.

Shorten the rod to

increase

tension and

speed.

Sensitivity:

Models prior to

Spec

R (Figure 24). There

are

coarse

and fine adjustments for sensitivity. The

coarse

adjustment is

made

by relocating the spring in

the

notches

in the governor arm.

Moving

the spring up

the governor arm

will

decrease

sensitivity. Fine adjust-

ment is

made

by changing the number of

effective

coils

in

the governor spring by turning the sensitivity stud

farther in or out. Turn the stud counterclockwise to

increase

sensitivity. Adjust for maximum sensitivity

without

a hunting condition.

Governor

High

Speed

Solenoid: This solenoid mounts on

the blower housing. When energized the plunger is in

the solenoid body. This

exerts

a

greater

than normal

force on the governor arm auxiliary spring (Figure 24),

holding

the governor wide open for high

speed

opera-

tion.

When de-energized the solenoid spring forces the

plunger out relaxing the auxiliary spring. Adjustments

can be

made

by changing length of solenoid linkage.

The solenoid contains two coils. Both are energized for

pulling

the plunger into the solenoid body. When the

plunger hits bottom, it

opens

a set of contacts, de-

energizing the

pull-in

coil.

The other

coil

holds the

plunger in.

To

test

the solenoid, check plunger operation and

current draw

with

12-volt input. Current draw

with

the

plunger up should be about one amp. If it is much

great-

er, the

contacts

did not open. If the plunger sticks,

remove and clean the plunger and

recess

in the sole-

noid.

Standard spring only

used

for lowest

speed.

Auxiliary

and standard springs are

used

for

higher

speeds.

\

GOVERNOR\

ARM

-

AUXILIARY

SPRING

USED

TO

INCREASE

SPEED

SPRING

FASTENED

TO

LEVER

HERE

STANDARD

SPRING

ADJUSTED

TO LOW

SPEED

WITH

AUXILIARY

SPRING

NOT

ENGAGED

FIGURE

24.

GOVERNOR

ADJUSTMENTS

(PRIOR

TO

SPEC

R)

24

Loading...

Loading...