Version 1.0 dated 2019-01-08 Page 55Translation of the original instructions

B13 basic | B14 basic | B16 basic GB

B13-B14-B16_basic_GB.fm

OPTIMUM

MASCHINEN - GERMANY

®

5.3 Repair

5.3.1 Customer service technician

For any repair work request the assistance of an authorised customer service technician. Con-

tact your specialist dealer if you do not have customer service's information or contact Stürmer

Maschinen GmbH in Germany who can provide you with a specialist dealer's contact informa-

tion. Optionally, the

Stürmer Maschinen GmbH

Dr. Robert-Pfleger-Str. 26

D- 96103 Hallstadt

can provide a customer service technician, however, the request for a customer service techni-

cian can only be made via your specialist dealer.

If the repairs are carried out by qualified technical personnel, they must follow the indications

given in these operating instructions.

Optimum Maschinen Germany GmbH accepts no liability nor does it guarantee against damage

and operating malfunctions resulting from failure to observe these operating instructions.

For repairs, only use

faultless and suitable tools only,

original parts or parts from series expressly authorised by Optimum Maschinen Germany

GmbH.

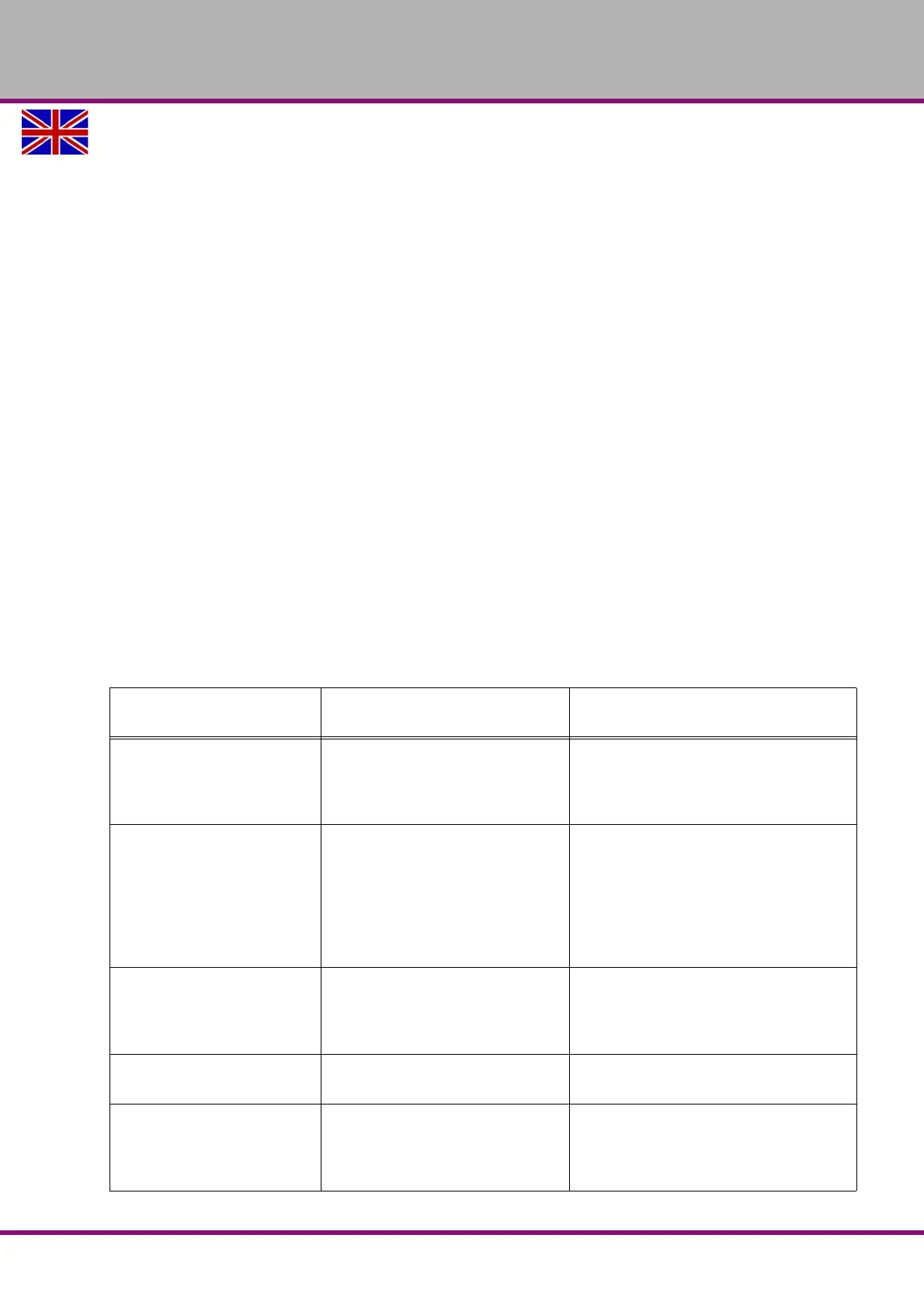

6 Malfunctions

Malfunction

Cause/

possible effects

Solution

Noise during work.

• Spindle is too little lubricated

• Tool is blunt or wrongly

clamped

• Grease spindle

• Use new tool and check tension

(fixed setting of the bit, drill chuck

and taper mandril)

Bit „burnt“

• Drill speed too high /feed too

high

• Chips do not come out of the

drill hole.

• Drill blunt

• No or too little cooling

• Select another speed

• Extract drill more often during work

• Sharpen or

use new drill

• Use coolant.

Drill tip is running off centre,

the drilled hole is non-round

• Hard points on the workpiece

• Length of the cutting spirals/or

angles on the tool are unequal

• Drill deformed

• Use new drill

Drill is defective

• No base / support used. • Use support and clamp it with the

workpiece

Drill is running non-round or

shaking

• Bit deformed

• Bearing worn down

• Drill is not correctly clamped.

• Drill chuck defective

• Use new drill

• Have the spindle bearings replaced

• Correctly clamp drill

• Replace the drill chuck

Loading...

Loading...