Version 1.0 dated 2019-01-08Page 56 Translation of the original instructions

B13 basic | B14 basic | B16 basicGB

B13-B14-B16_basic_GB.fm

OPTIMUM

MASCHINEN - GERMANY

®

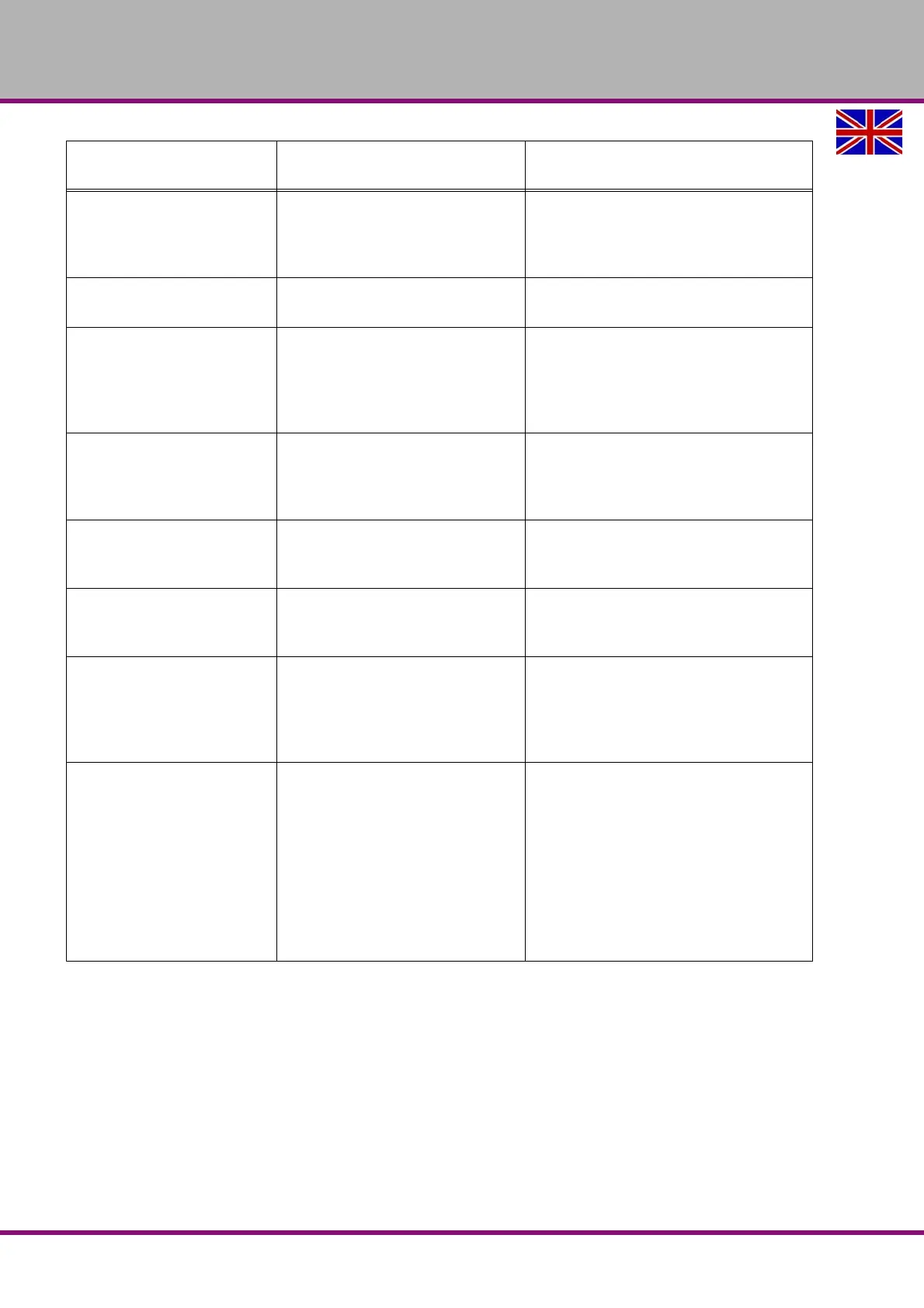

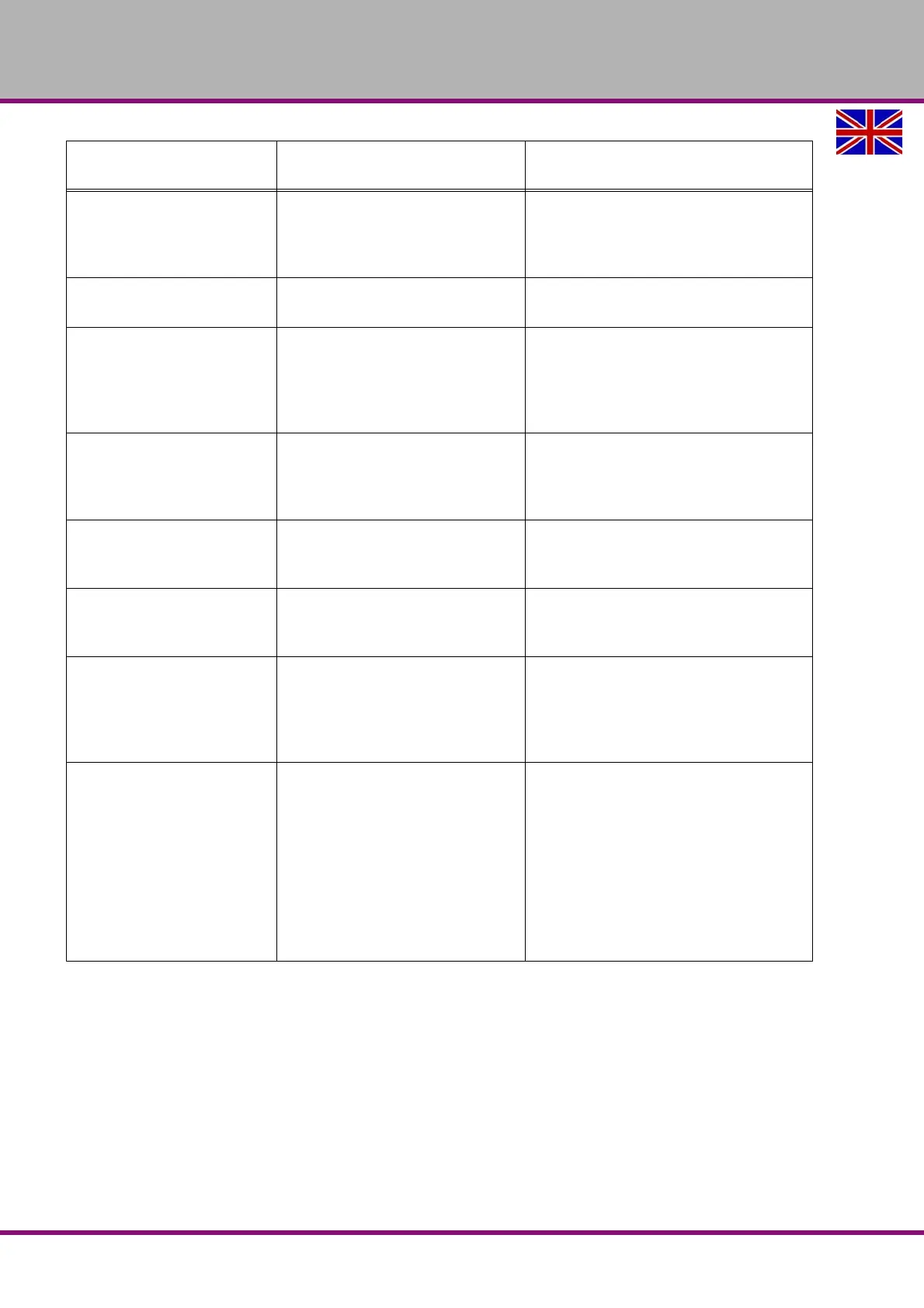

The drill chuck or the taper

mandrel cannot be inserted.

• Dirt, grease or oil on the taper

inside of the drill chuck or on

the taper surface of the drill

spindle

• Clean surfaces well

• Keep surfaces free of grease

Motor does not start.

• Motor is wrongly connected

• Fuse is defective

• Have it checked by qualified

Motor is overheating and there

is no power

• Motor overloaded?

• Too low mains voltage

• Motor is wrongly connected

• Reduce feed

Disconnect immediately and have it

checked by authorized personnel

• Have it checked by qualified

Precision of the work deficient

• Irregularly heavy or tensed

workpiece

• Inexact horizontal position of

the work-piece holder

• Balance the piece statically and

secure without straining

• Adjust workpiece-holder

Drilling spindle sleeve does not

return to its initial position

• Spindle return spring does not

work

• Locking bolt inserted

• Check spindle return spring, replace

it, if necessary

• Pull out locking pin

The drilling sleeve may not be

moved downwards.

• Locking bolt inserted

• Drill depth adjustment no

released

• Pull out locking pin

• Release drill depth adjustment

Spindle bearing overheating

• Bearing worn down

• Bearing pretension is too high

• Working at high drilling speed

over a longer period of time.

•Replacing

• Increase bearing clearance for fixed

bearing (taper roller bearing)

• Reduce drill speed and feed rate

Rattle the spindle if the work-

piece surface is rough.

• Excessive slack in bearing.

• Spindle moves up and down

• Adjustment strip loose

• Clamping chuck is loose

• Tool is blunt.

• Workpiece is loose

• Readjust the bearing slack or

replace the bearing.

• Readjust bearing clearance (fixed

bearing)?

• Adjust strip to the correct slack

using the adjusting screw

• Check, re-tighten

• Sharpen or renew the tool.

• Clamp the workpiece firmly.

Malfunction

Cause/

possible effects

Solution

Loading...

Loading...