12 - PVD 3674_GB_K Series_CE-November 2016.Docx

3.1.3. Thermal equivalent torque (rms torque)

The selection of the right kit can be made through the calculation of the rms torque

M

rms

(i.e. root mean squared torque) (sometimes called equivalent torque).

This calculation does not take into account the thermal time constant. It can be used

only if the overload time is much shorter than the copper thermal time constant.

The rms torque M

rms

reflects the heating of the kit during its duty cycle.

Let us consider:

- the period of the cycle T [s],

- the successively samples of movements i characterized each ones by the maximal

torque M

i

[Nm] reached during the duration

t

i

[s].

So, the rms torque M

rms

can be calculated through the following basic formula:

Example:

For a cycle of 2s at 0 Nm and 2s at 10Nm and a period of 4 s, the rms torque is

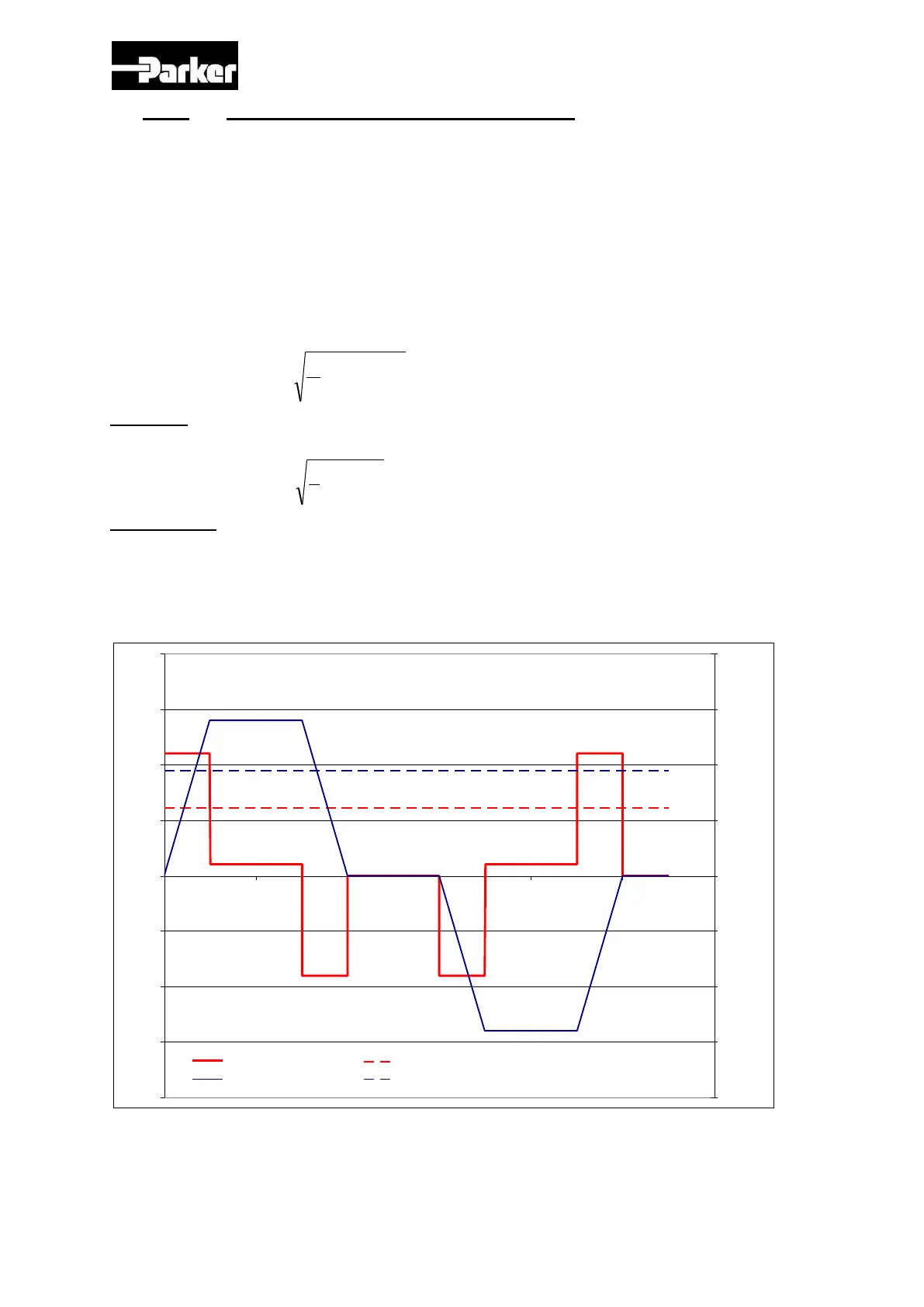

Illustration :

Acceleration-deceleration torque: 10 Nm for 0,1 s.

Resistant torque: 1 Nm during all the movement.

Max-min speed: 2800 rpm during 0,2 s.

Max torque provided by the motor: 11 Nm.

rms torque: 6 Nm.

The maximal torque M

i

delivered by the kit at each segment i of movement is obtained

by the algebric sum of the acceleration-deceleration torque and the resistant torque.

Therefore, M

max

corresponds to the maximal value of M

i

.

Loading...

Loading...