4

P1D Cylinder

05.03

www.parker.com/euro_pneumatic

P1D Standard

The innovative P1D is a future-proof generation of ISO/

VDMA cylinders. The cylinders are double-acting, with a

new design of air cushioning. The light, stiff body extrusion

has sensor grooves for simple and protected sensor

installation.

Installation dimensions according to international

standards

The new P1D complies with the current ISO 6431,

ISO 15552, VDMA 24562 and AFNOR installation

dimension standards. For customer reassurance world-

wide.

High technology design

The best materials, manufacturing methods and design of

every detail have been carefully tested, to give the best

possible product. The internal components are made of

high strength plastics, for quiet operation and long service

life. The aluminium end caps and the torsionally stiff

aluminium body extrusion make the cylinder robust and

suitable for a wide range of applications.

High quality

The P1D has been developed with quality in all phases –

requirement specification, design, planning, purchasing,

production, distribution and service. We have been

certified under the ISO 9001 QA standard for the past ten

years. Quality in all our products and services is our

watchword.

Even more functions and variants

The P1D is available with all the usual optional designs,

such as: Through piston rod, high and low temperature,

hydraulic operation, extended piston rod etc.

A new special variant is the unique self-lubricating

HDPE scraper ring and piston rod seal, specially

designed for operation with a completely dry piston rod

(i.e. applications where the film of grease on the piston rod

is regularly washed off).

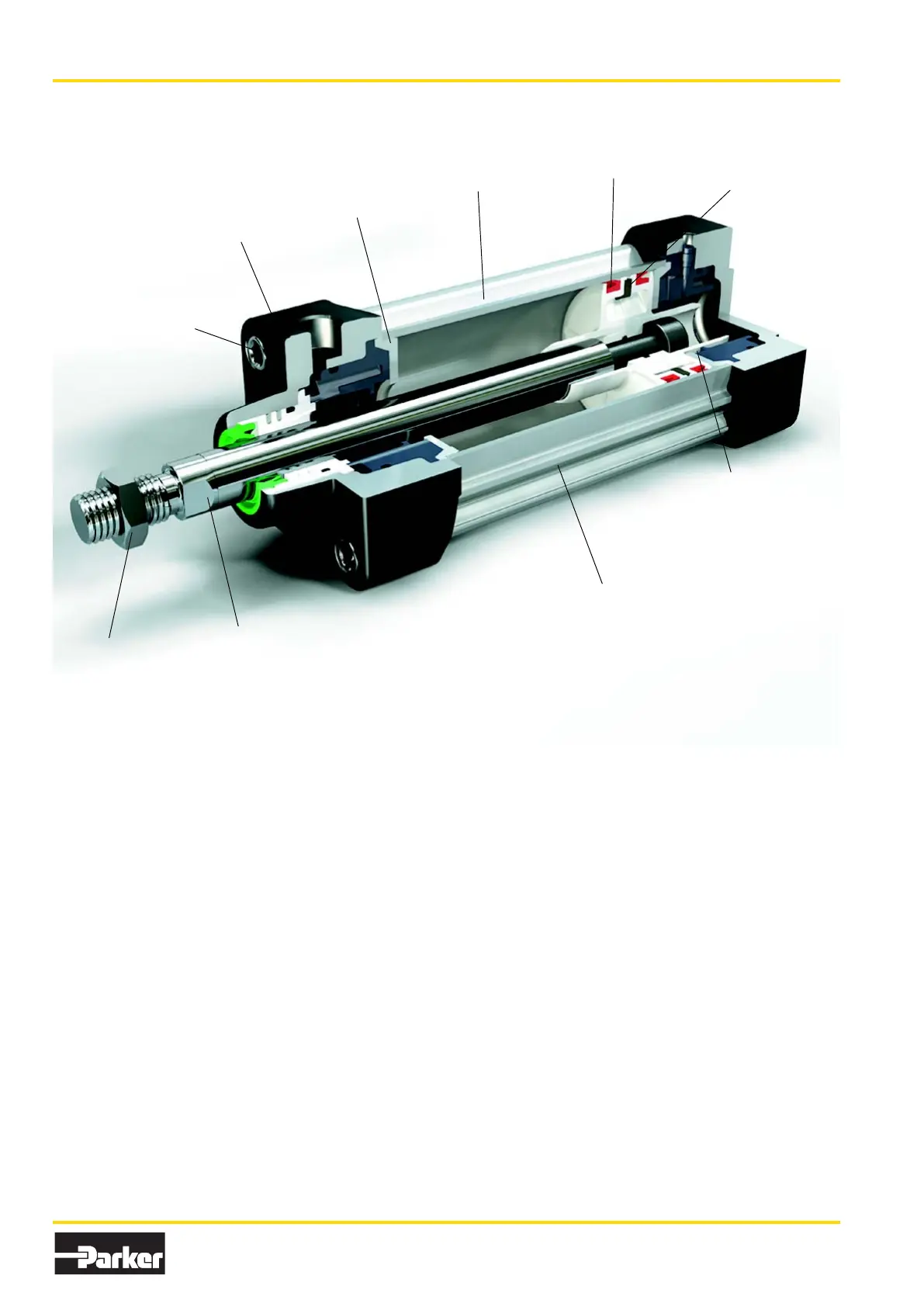

Surface treated steel

end cover nuts for

tough environments.

Sealing plugs are

available for all P1D

cylinders.

All seals are made from

polyurethane, which

gives P1D cylinders

extra long service life.

P1D Standard has a

further development

of our famous body

extrusion with

grooves for the new

”drop-in” sensors.

The cylinder end covers

do not have any cavities

or pockets which could

collect water or dirt. This

facilitates effective

cleaning.

The body extrusion is

anodised inside and

outside, for long life

and low friction.

The cylinders have

magnetic pistons

as standard.

Polyurethane end-

of-stroke washers

give smooth and

quiet operation.

One piston rod

nut according

to ISO 439B is

included as

standard.

P1D has a stainless steel

piston rod as standard.

Hard chromed steel, hard

chromed stainless steel

and acid-proof steel are

available as options.

All P1D cylinders for

normal temperature

have initial greasing of a

transparent, non-toxic

grease, approved by

the food industry, which

is entirely free from

PTFE and silicone.

The cushioning has

individual flow geometry

for each cylinder size.

This gives effective

cushioning which is

easier to set and adjust.

Loading...

Loading...