Disassembling and inspection

1. Drain oil, and remove the cotter pin.

2. Put a piece of wood between propeller and anti-swirl baffle. Remove hexagon nut, anode and

water inlet.

3. Remove propeller assembly and cushion.

4. Remove anode.

5. Remove the lower casing cover.

Remove reverse gear and shim. Remove oil seal.

6. Remove propeller shaft assembly.

7. Remove shift plunger.

8. Remove clutch ring, remove clutch pin and dog clutch. Remove clutch spring.

9. Remove the drive shaft by using female spline spanner. Remove forward gear.

Female spline spanner

10. Remove drive shaft base.

11. Remove shift rod cam assy.

12. Remove rolling needle bearing from lower unit.

Rolling needle bearing installer

13. Remove oil seal and barrel bearing with guard board from the drive shaft base.

Propeller shaft and clutch block

1. Check dog clutch for crack or damage. Replace if necessary.

2. Check propeller shaft for wear or crank. Replace if necessary.

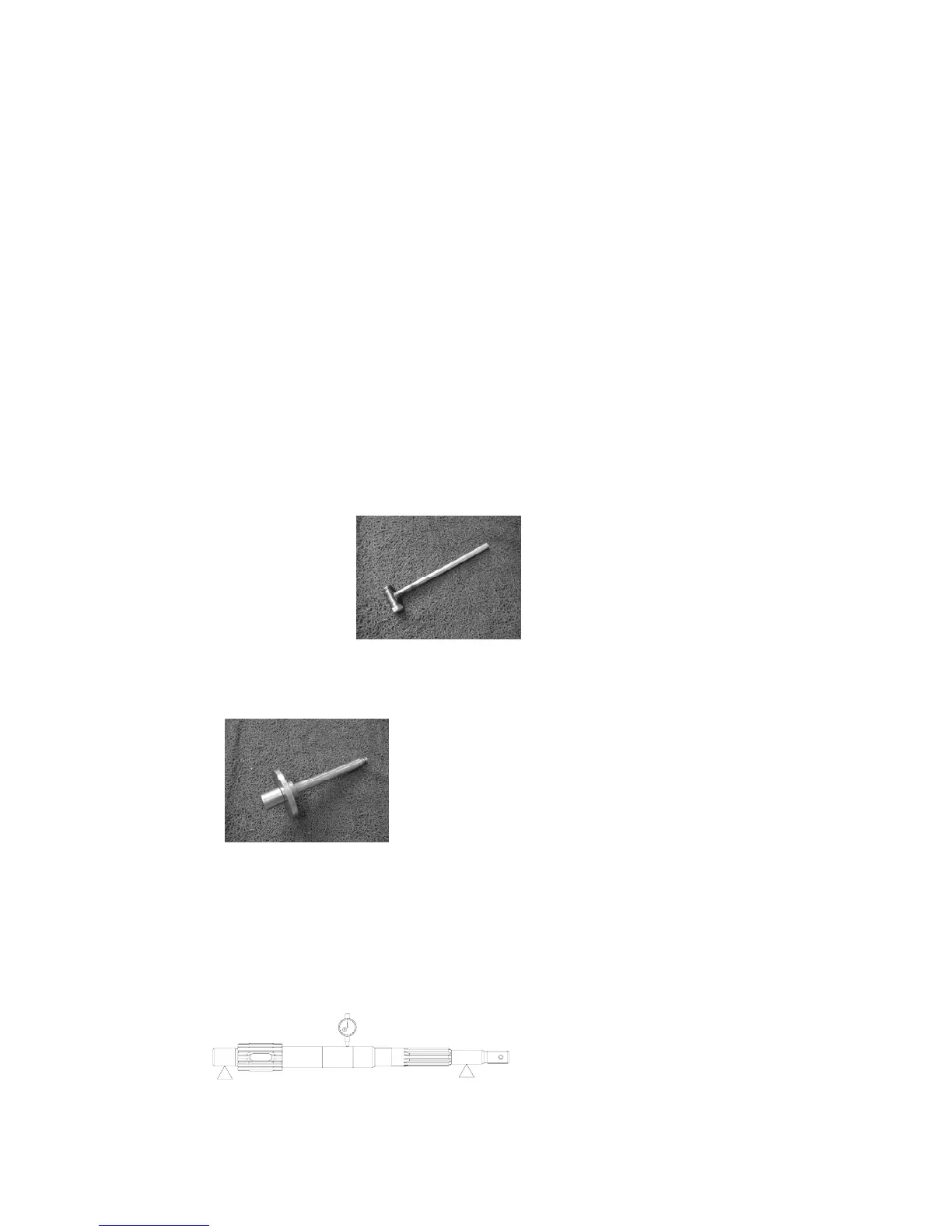

3. Check the run out of propeller shaft. If out of specification, replace.

Run out limit: 0.05mm

94

Loading...

Loading...