Don’t rotate the flywheel counter clockwise in case the valve system is damaged.

NOTE:

Adjust the valve clearance when the engine is cold.

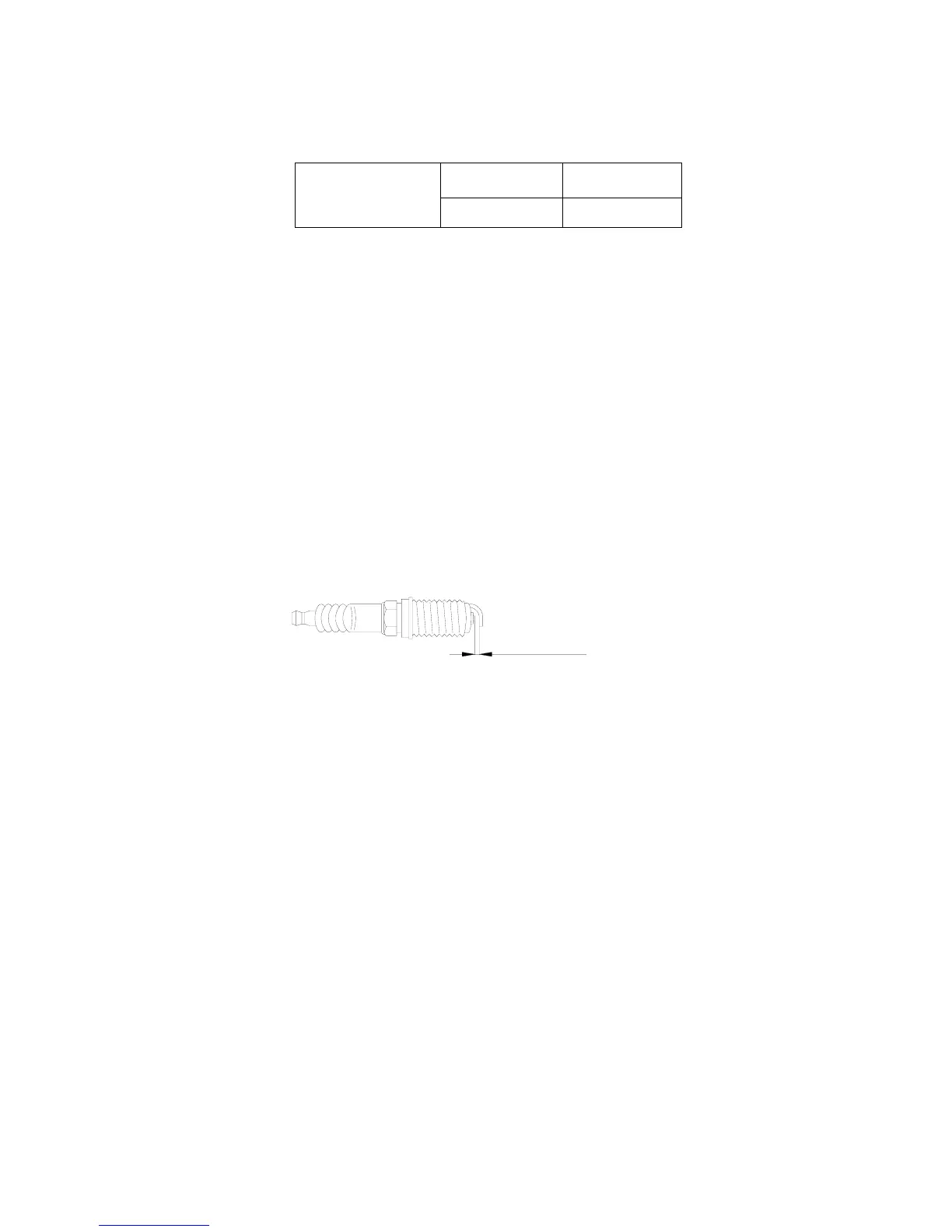

Intake valve 0.15~0.25mm

Valve clearance

(cold position)

Exhaust valve 0.20~0.30mm

6. Loose lock nut, rotate adjusting bolt to reach the specified valve clearance.

NOTE:

Rotate adjusting bolt clockwise to reduce the valve clearance.

Rotate adjusting bolt counter clockwise to increase the valve clearance.

7. Re-assemble the spare parts.

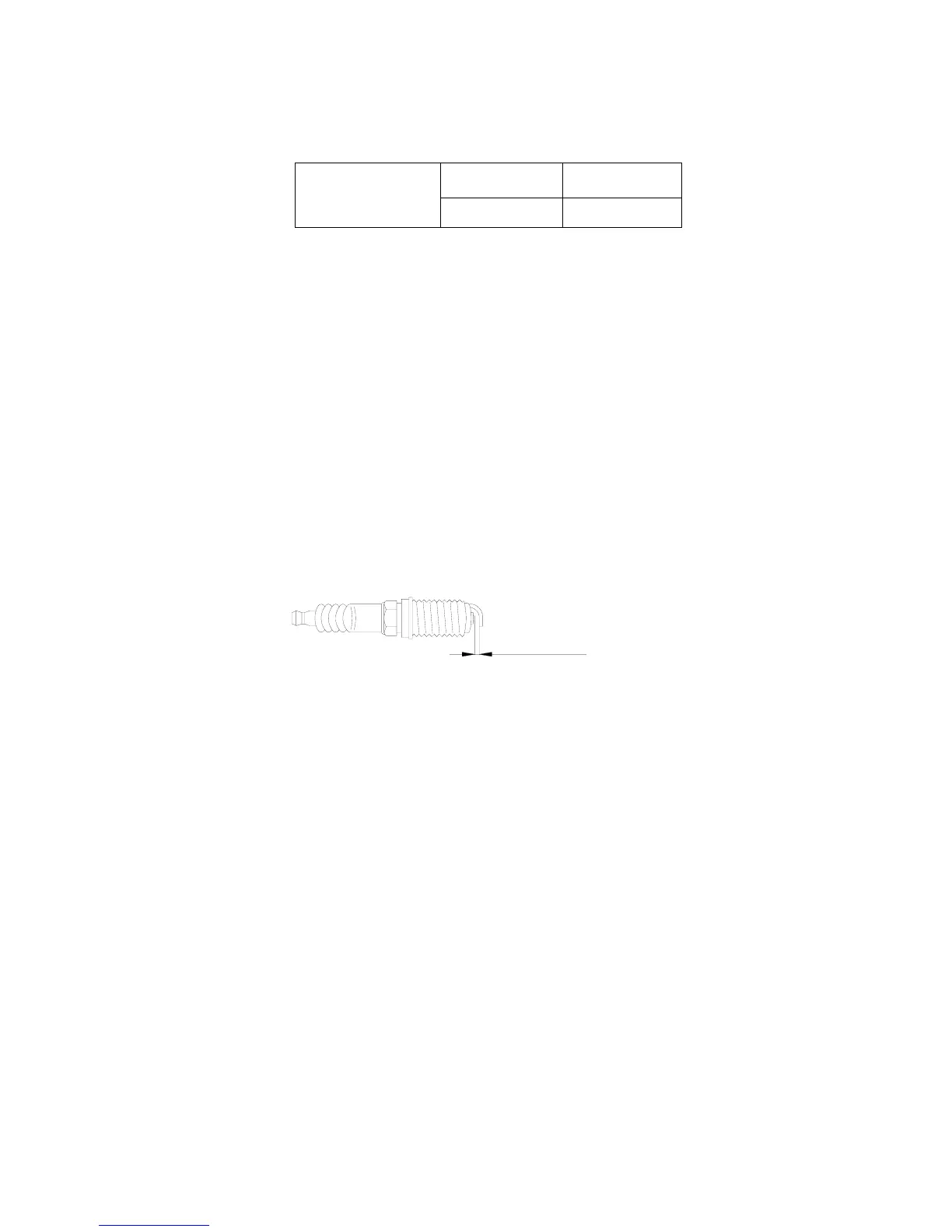

Spark plug

1. Remove spark plug cap and spark plug.

2. Clean off carbon build-up on the electrodes.

3. Check if the electrodes are corroded or have deposit, or if the washer is damaged. If necessary,

change the spark plug.

Spark plug type:DPR7HS

4. Inspect if the spark plug gap is within specification. If necessary, change the spark plug.

0.8-0.9mm

5. Install spark plug. Use spark plug spanner to t rding to specified torque.

CONTROL SYSTEM

Recoil start type

e grip to fully closed position.

Check if the throttle cable is slack, if the throttle lever touches the throttle stop screw, or if the

Loosen the throttle cable adjusting screw, adjust the throttle cable position, and tighten throttle cable

ighten it acco

Specified torque: 18 Nm

Throttle grip

1. Turn the throttl

2.

arresting stop on the throttle accelerograph enforce touches the check plate on the fixed mount.

3.

adjusting screw.

17

Loading...

Loading...