3. Lap the valve on valve seat by valve lapping tool.

4. Measure the valve seat width.

The valve face is with bluing dye.

If the valve and valve seat do not match, or the valve seat width does not conform to specified value,

reface and lap the valve seat.

If the contact surface is not even, replace the valve guide bush.

The valve seat width: 0.6~0.8mm

The maximum valve seat width: 1.1mm

Valve seat cutting

1. Use 45

o

valve seat cutter to adjust the valve seat width. Turn the cutter clockwise until the valve

seat face is smooth.

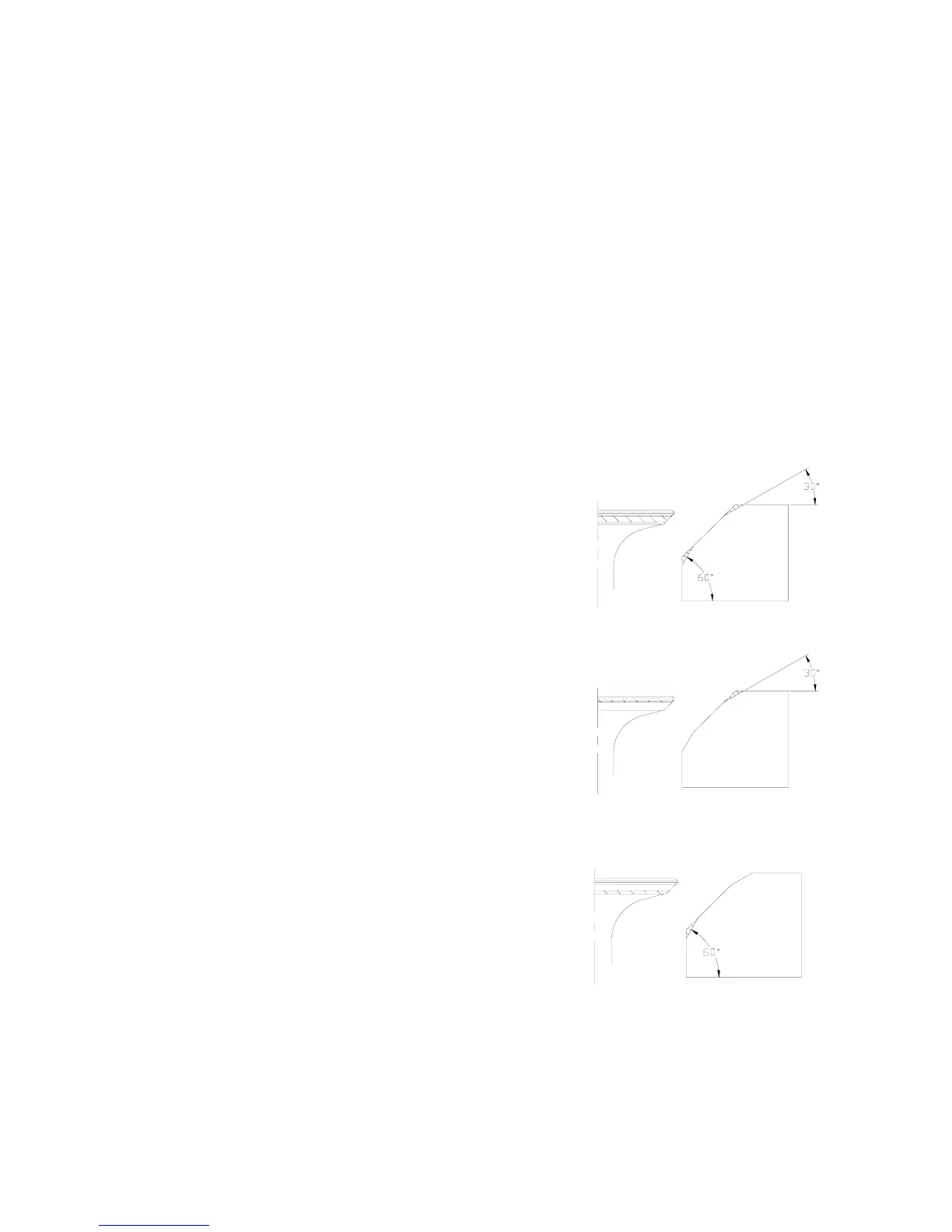

2. If the valve seat is centered on the valve face but it’s too wide, to reduce the valve seat width, use

30

o

cutter to adjust the top edge of the seat, and use 60

o

cutter to adjust the bottom edge of the seat.

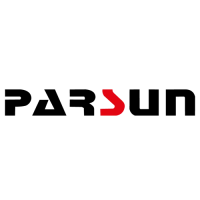

3. If the valve seat is too narrow and on the top edge of valve surface, use 30

o

cutter to adjust the top

margin of the seat, and use 45

o

cutter to adjust the valve seat width if necessary.

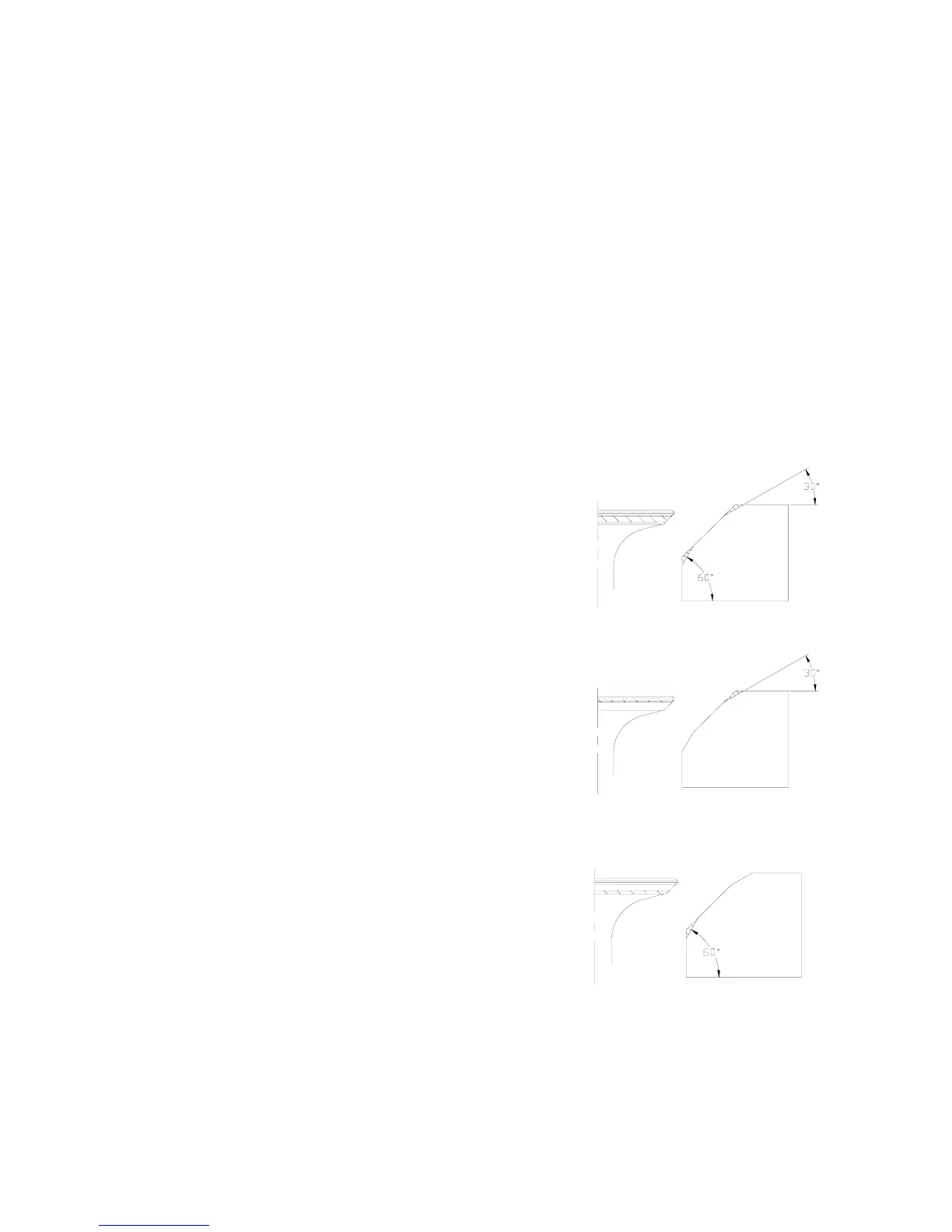

4. If the valve seal surface is too narrow and on the bottom edge of valve surface, use 60

o

cutter to

adjust the bottom edge of the seat, and use 45

o

cutter to adjust the valve seat width if necessary.

5. Coat evenly a thin layer of lapping compound onto valve seat, and lap the valve by lapping tool.

6. Clean up the remaining lapping compound.

7. Inspect again the valve seat width.

60

Loading...

Loading...