7. Force a prescribed negative pressure and check for leakage. Disassemble the fuel pump to check if

necessary.

Prescribed pressure: 50kPa

8. Remove four bolts, and separate fuel pump cover from fuel pump seat.

9. Remove the valve screw from fuel pump, and remove the valve plate.

10. Press the plunger and diaphragm, rotate the fuel pump seat, and align the notch with the notch on the

plunger. Take the roller needle out.

11. Inspect the diaphragm for crack and valve for damage. Replace if necessary.

12. Reverse above step 8 to step 10 to install the fuel pump.

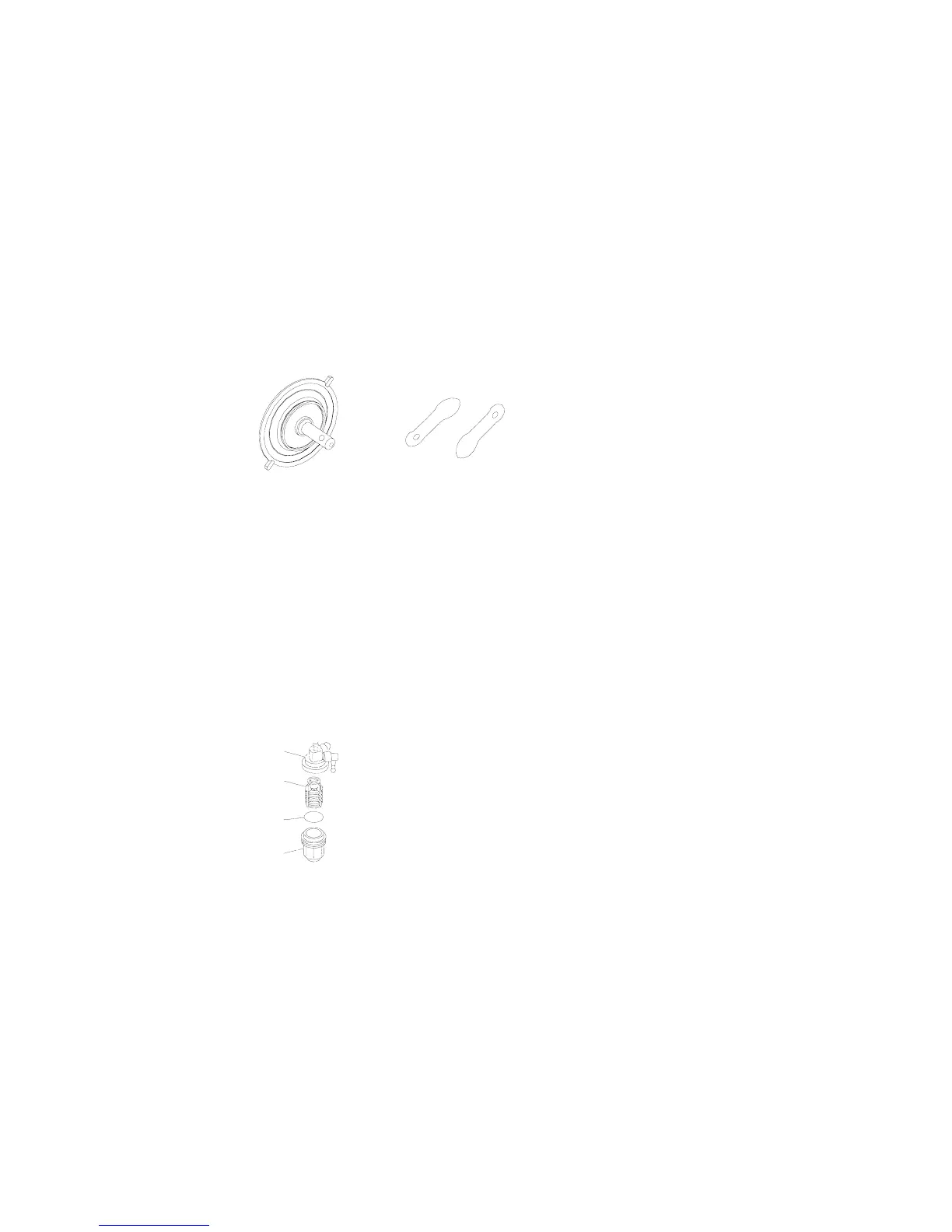

FILTER INSPECTION

Check if the filter element is clogged or with foreign matter. Check the filter cup for damage or leakage.

Use gasoline to clean it, or replace if necessary.

NOTE:

Coat a layer of gasoline onto the O-ring before installing the filter cup.

1. Filter cup

2. O-ring

3. Filter element

4. Filter cap

1

2

3

4

45

Loading...

Loading...