NOTE:

Don’t remove bearing unless you replace it.

Oil seal housing

1. Inspect oil seal housing for crack/damage. Replace if necessary.

2. Inspect O-ring for crack/damage. Replace if necessary.

Crankcase and crankcase cover

1. Inspect crankcase cover. If cracked/damaged, replace.

2. Inspect cooling water passage for dirt or clog. Clean if necessary.

FULL INSTALLATION

Piston connecting rod installation

Install piston, connecting rod, piston pin and piston pin circlip.

NOTE:

When installing, make sure that the mark on the connecting rod is at the same side of the mark on

the piston crown.

Use new piston pin circlip. Make sure that circlip gap is not aligned with the circlip slot gap.

Piston ring installation

1. Install oil ring, 2nd ring and top ring.

NOTE:

Make sure that the mark is toward the piston crown when installing the 2nd ring.

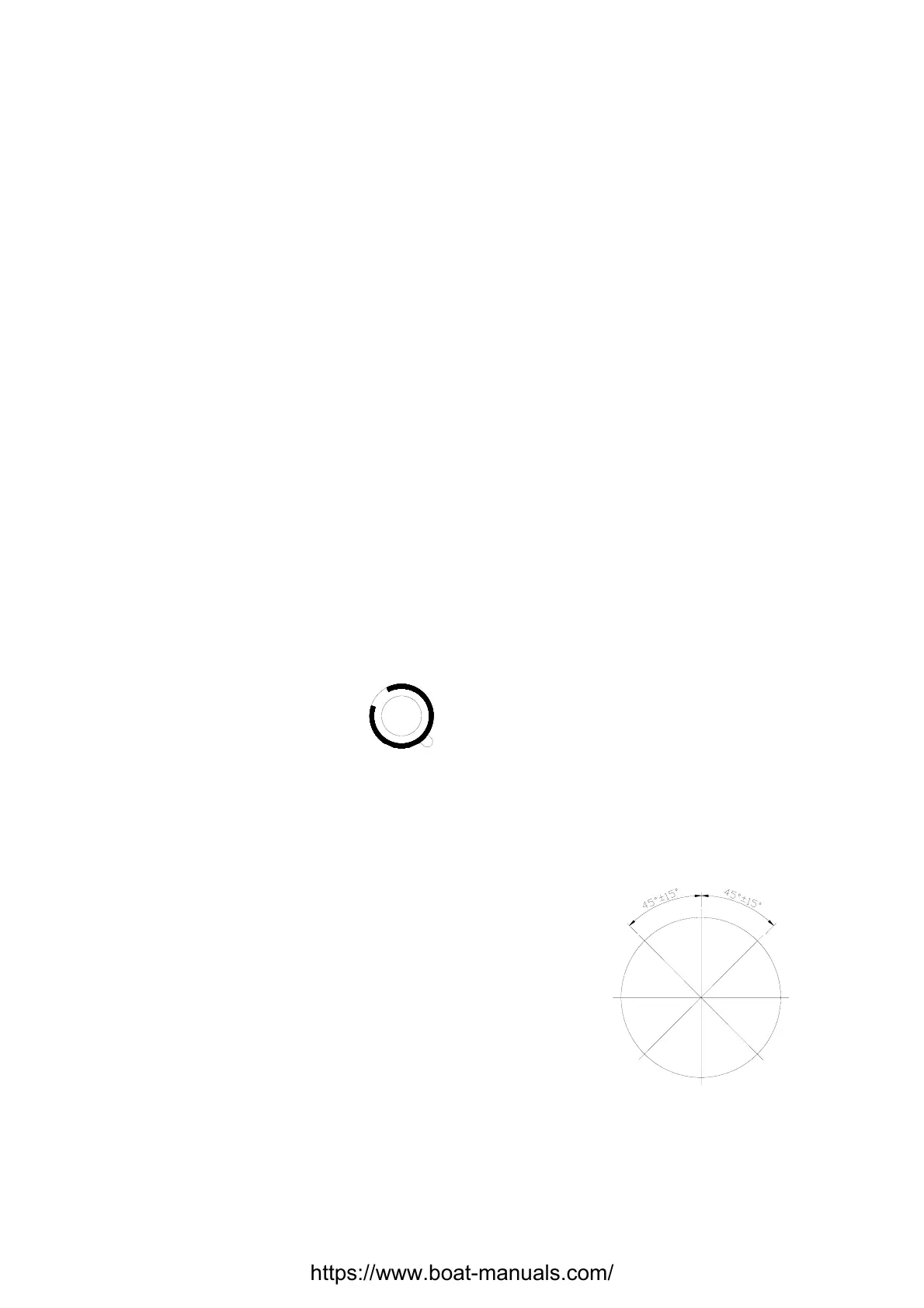

2. Picture of the piston ring gap

Oil ring end gap 1 (lower rail)

Oil ring end gap 2 (expanded ring)

Oil ring end gap 3 (upper rail)

2nd piston ring end gap 4

Top piston ring end gap 5

UP

34

12、5

Piston installation

Use piston slider to install piston, and make sure the piston crown “UP” is toward the flywheel side.

56

https://www.boat-manuals.com/

Loading...

Loading...