6. SERVICE

. ..E. HYDRAULIC SYSTEM...

Hydraulic Motor

1. Make certain the pump and control valve have

been checked for proper flow and pressure before

attributing a “loss of power” problem to the

hydraulic motor.

2. Individual components of hydraulic motors are

repairable as indicated in the parts drawing.

Replacement of the complete assembly is not

necessary or authorized in the warranty period

unless the combined cost of the worn, damaged

3.

or defective parts exceeds the cost of the

assembly.

Before disassembling the motor, try turning the

shaft manually. The shaft should turn smoothly

with light to moderate resistance. If the shaft

fails to turn, is very hard to turn, or turns

roughly, this may indicate internal damage,

misalignment, etc.

Disassembly

IMPORTANPI’NOTE: Before repairing the hydraulic

NOTE: Repair of the motor itself does not require

motor, clean it thoroughly to prevent dirt from

removing the motor from the saw frame. However,

contaminating the internal parts. Also make sure the

control valve repair does require removing motor from

work area is clean.

saw frame.

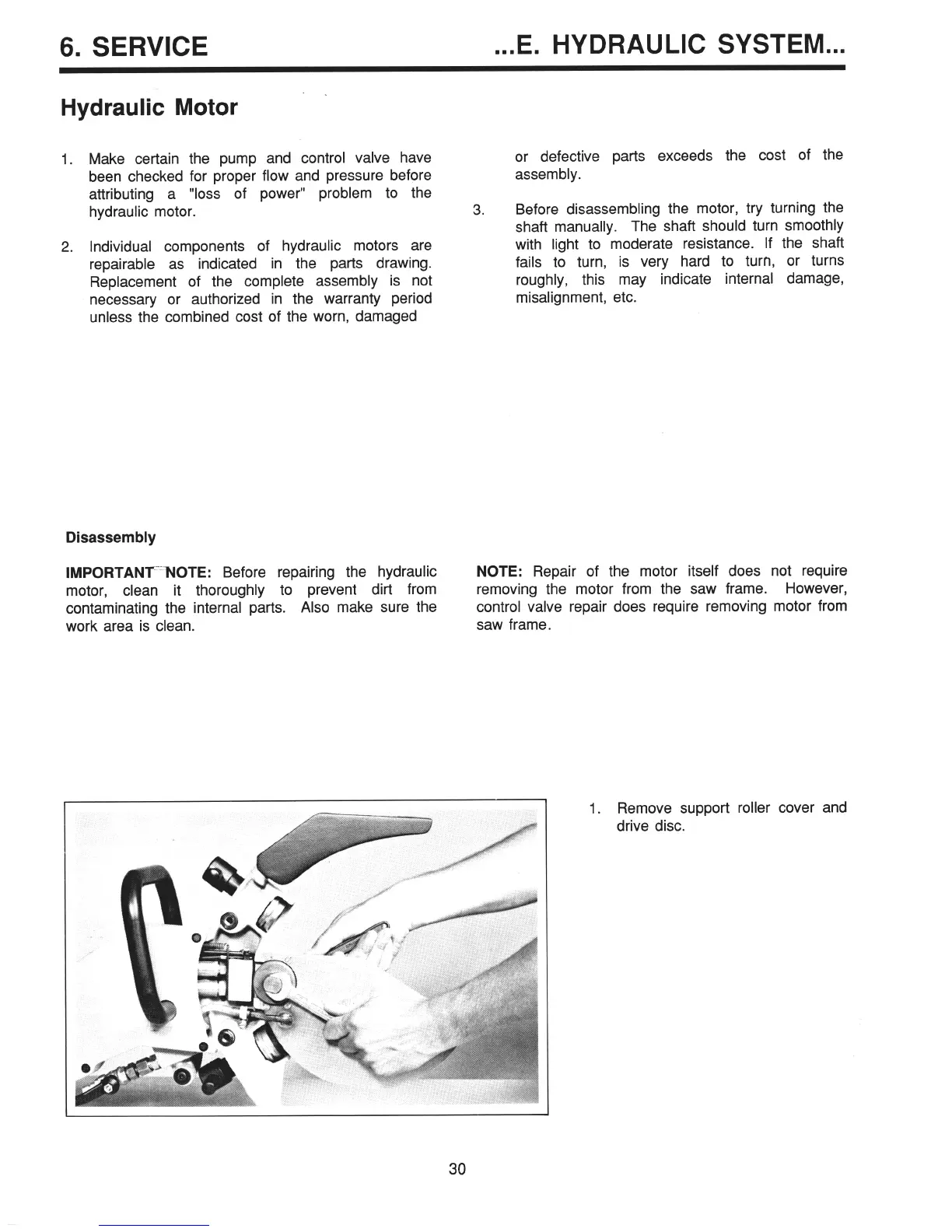

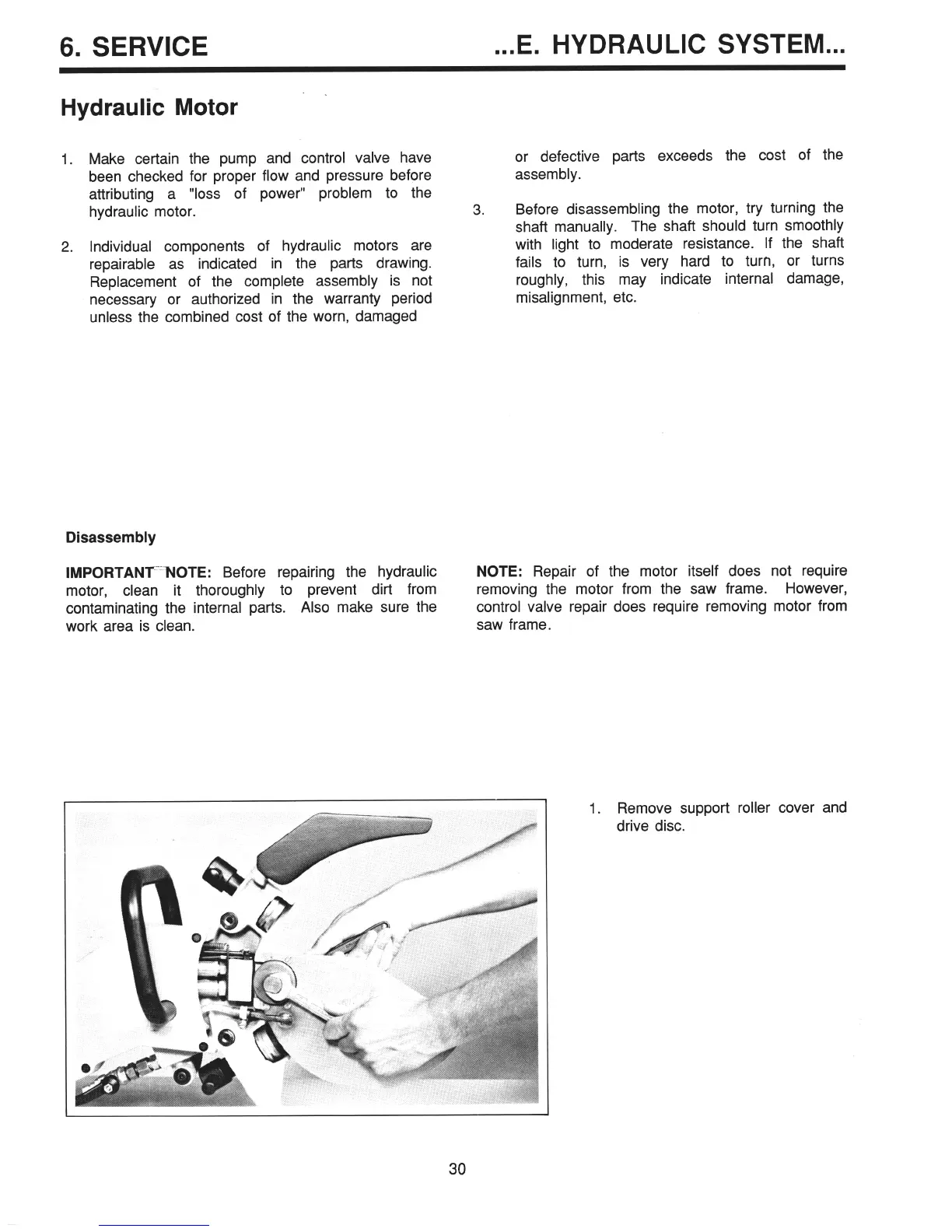

1. Remove support roller cover and

drive disc.

Loading...

Loading...