6. SERVICE

. ..E. HYDRAULIC SYSTEM...

,.

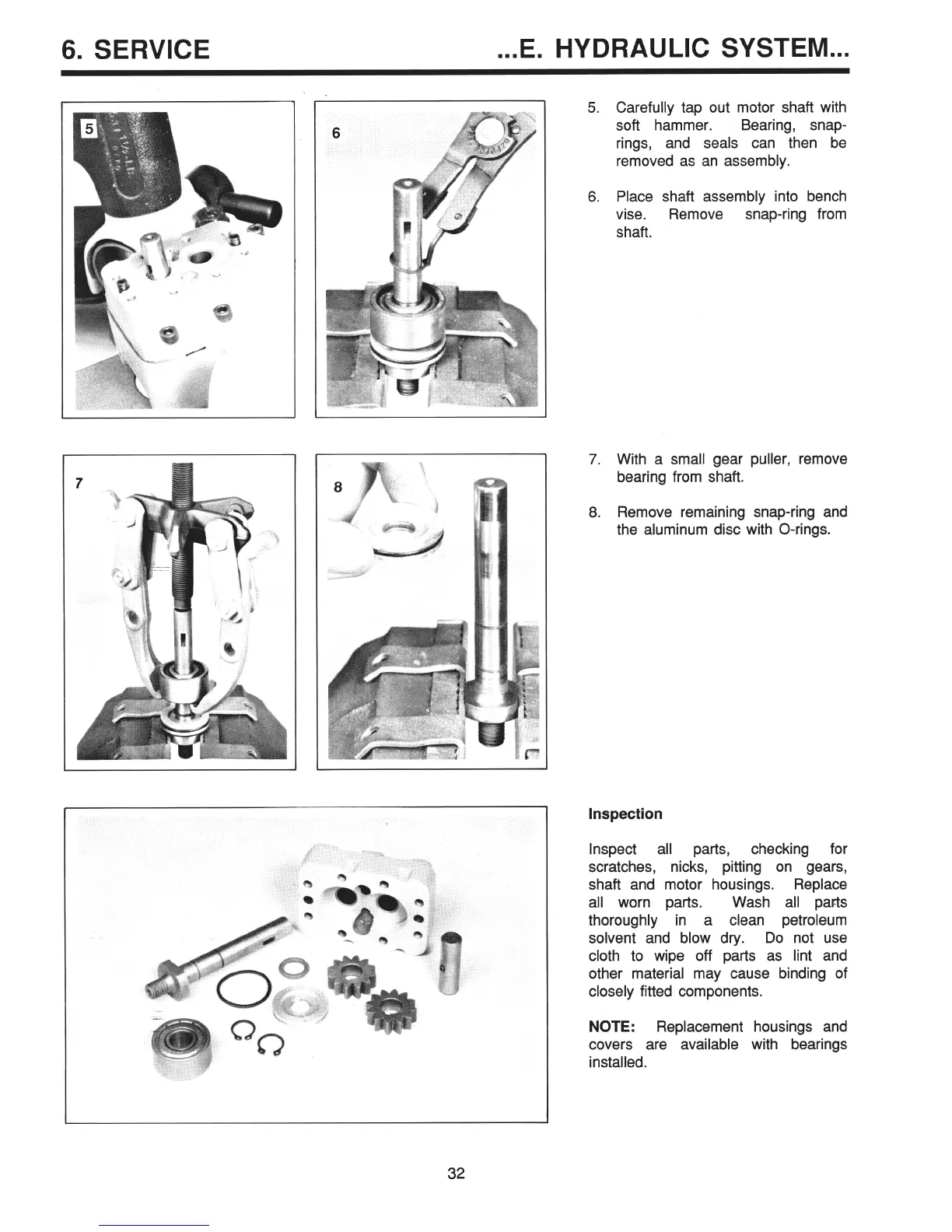

5. Carefully tap out motor shaft with

soft hammer.

Bearing, snap-

rings, and seals can then be

removed as an assembly.

6. Place shaft assembly into bench

vise. Remove

snap-ring from

shaft.

7. With a small gear puller, remove

bearing from shaft.

8. Remove remaining snap-ring and

the aluminum disc with O-rings.

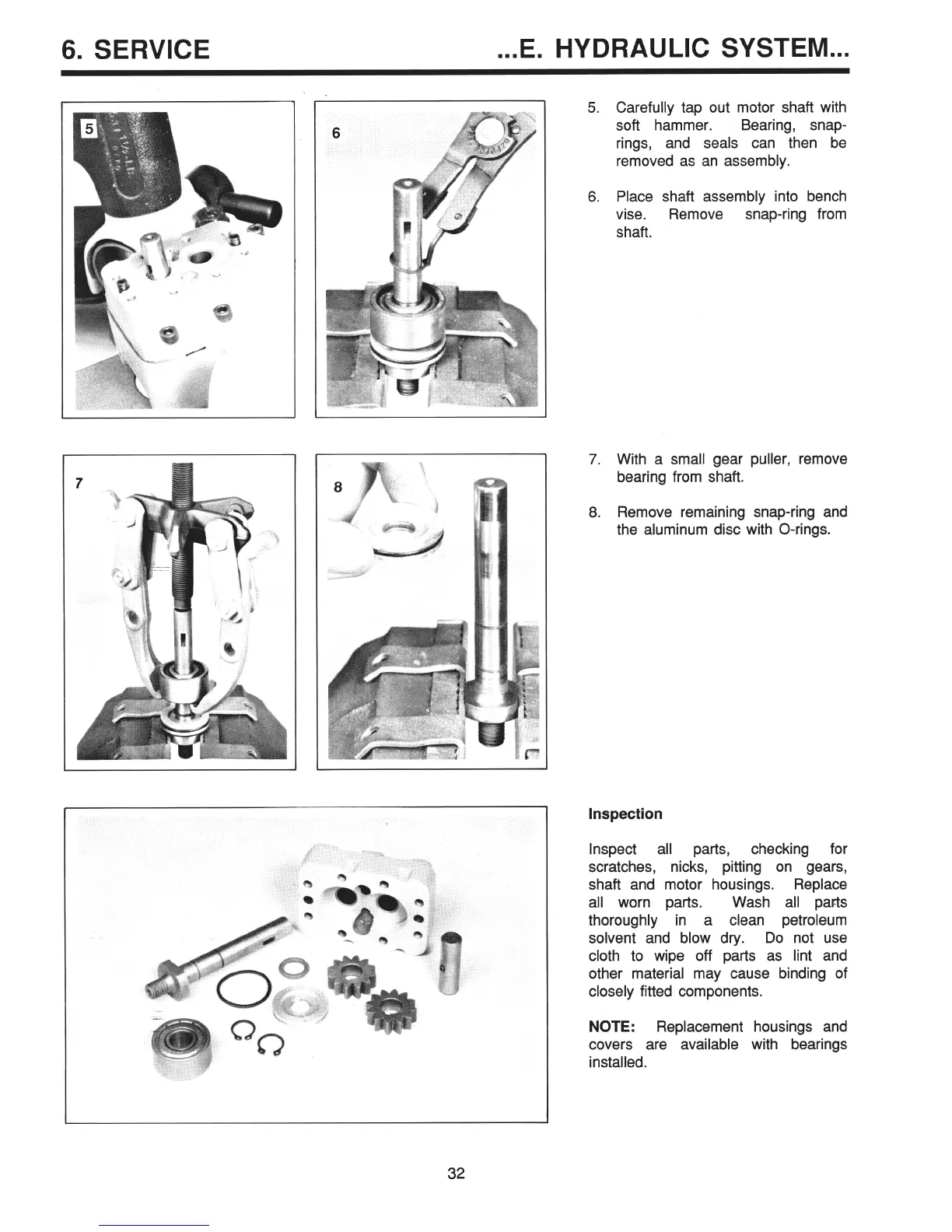

Inspection

Inspect all parts, checking for

scratches, nicks, pitting on gears,

shaft and motor housings.

Replace

all worn parts. Wash all parts

thoroughly in a clean petroleum

solvent and blow dry.

Do not use

cloth to wipe off parts as lint and

other material may cause binding of

closely fitted components.

NOTE: Replacement housings and

covers are available with bearings

installed.

32

Loading...

Loading...