>

8: 6. SERVICE

. ..E. HYDRAULIC SYSTEM...

..

:-“uA*a*-”

COUNTERBORE UP

10B

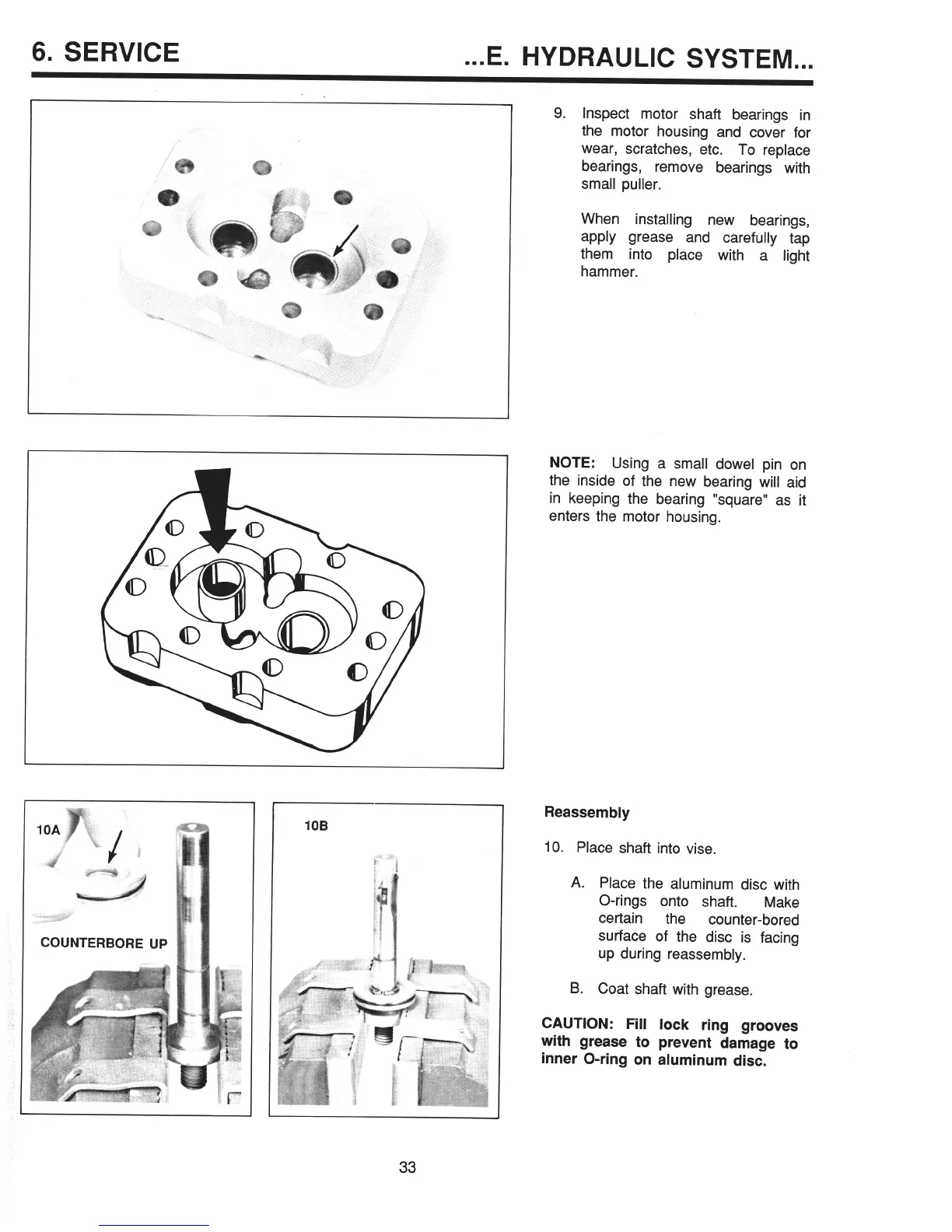

9. Inspect motor shaft bearings in

the motor housing and cover for

wear, scratches, etc. To replace

bearings, remove bearings with

small puller.

When installing new bearings,

apply grease and carefully tap

them into place with a light

hammer.

NOTE: Using a small dowel pin on

the inside of the new bearing will aid

in keeping the bearing “square” as it

enters the motor housing.

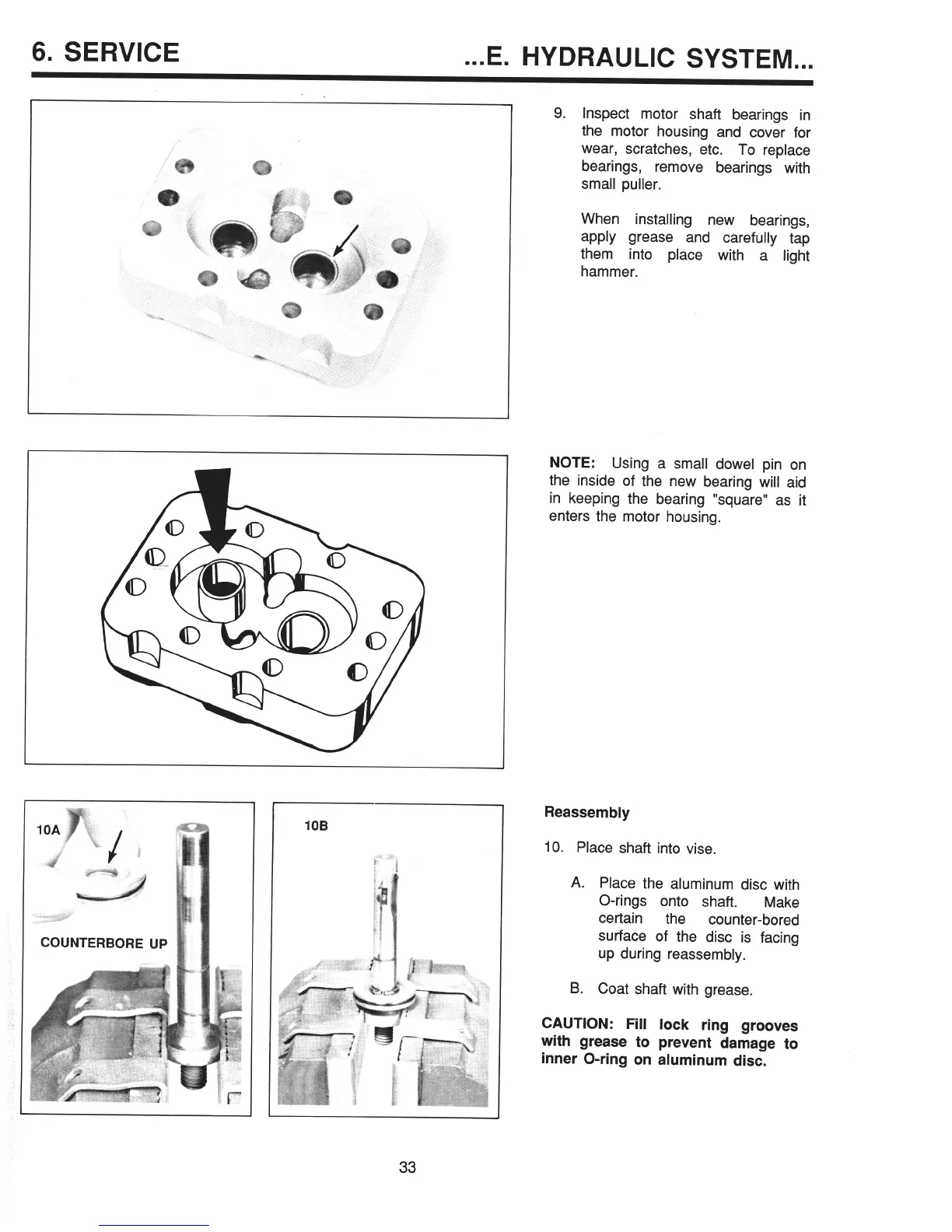

Reassembly

10. Place shaft into vise.

A. Place the aluminum disc with

O-rings onto shaft.

Make

certain

the

counter-bored

surface of the disc is facing

up during reassembly.

B. Coat shaft with grease.

CAUTION: Fill lock ring grooves

with grease to prevent damage to

inner O-ring on aluminum disc.

33

Loading...

Loading...