C. ACCESSIBILITY CLEARANCES

1. The PUREFIRE

®

boiler is certified for closet installations

with zero clearance to combustible construction. In

addition, it is design certified for use on combustible

floors. Do not install on carpeting.

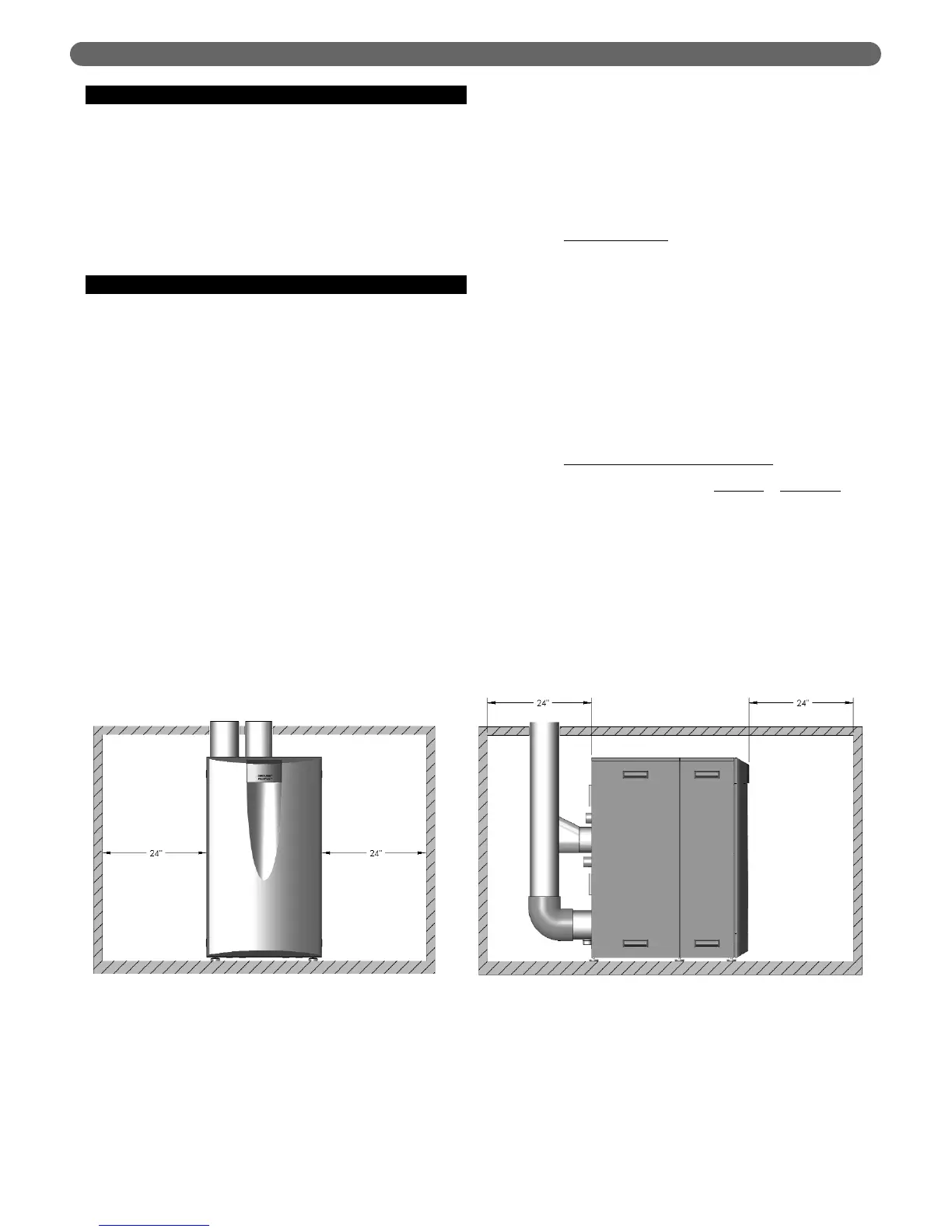

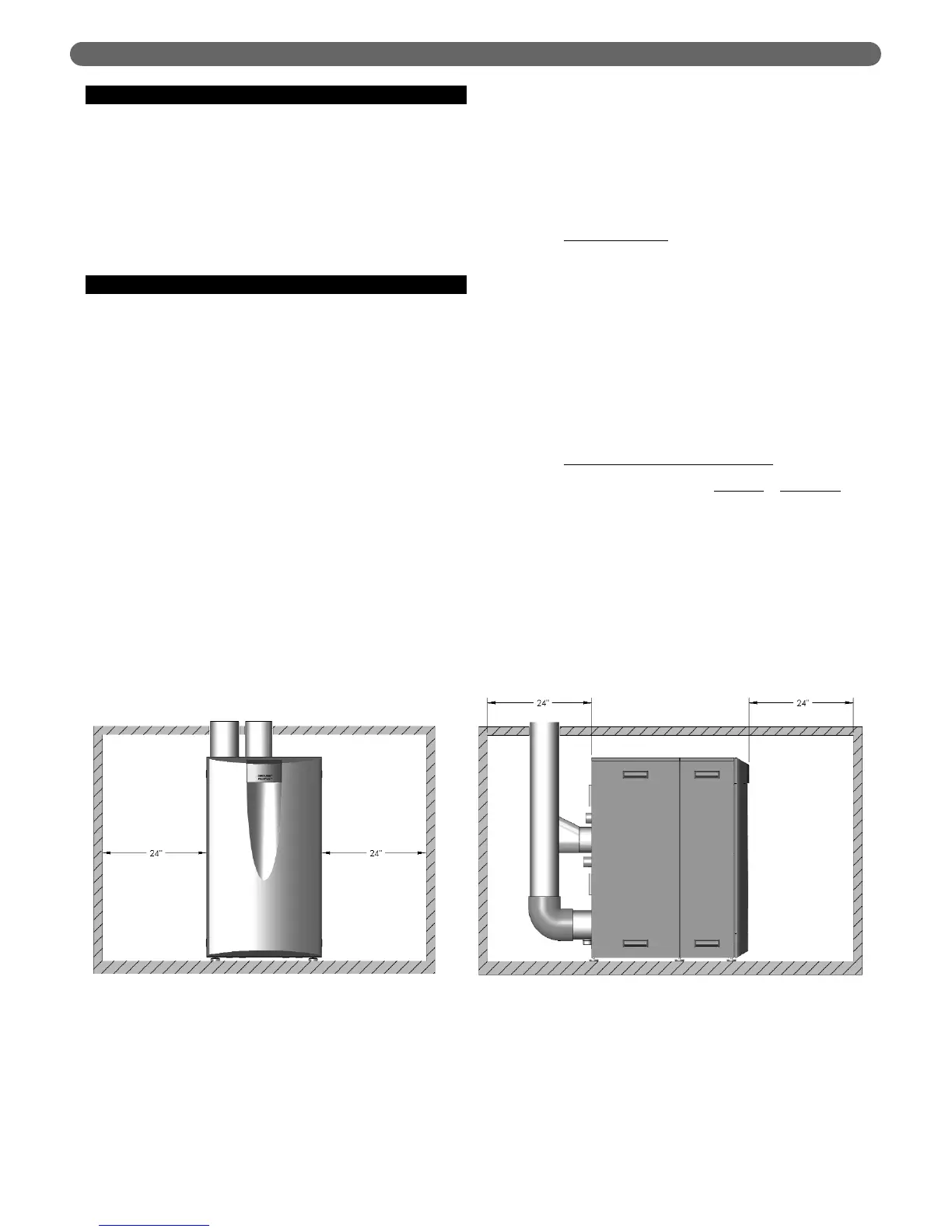

2. Figure 1.1 shows the minimum recommended

clearances to allow reasonable access to the boiler for

inspection and maintenance. However, local codes or

special conditions may require greater clearances.

D. COMBUSTION AND VENTILATION AIR

1. The PUREFIRE

®

boiler is designed for operation with

combustion air piped directly to the boiler from

outside the building (sealed combustion). Combustion

air can be supplied from within the building only if

adequate combustion and ventilation air is provided

in accordance with the section of the National Fuel

Gas Code entitled, “Air for Combustion and

Ventilation” or applicable provisions of the local

building codes.

2. If the combustion air is piped directly to the boiler

from outside the building, no additional combustion

or ventilation air is required. Otherwise, follow the

National Fuel Gas Code recommendations

summarized in subsections 3 through 10.

3. Required Combustion Air Volume: The total required

volume of indoor air is to be the sum of the required

volumes for all appliances located within the space.

Rooms communicating directly with the space in

which the appliances are installed and through

combustion air openings sized as indicated in

Subsection 3 are considered part of the required

volume. The required volume of indoor air is to be

determined by one of two methods.

a. Standard Method

: The minimum required volume

of indoor air (room volume) shall be 50 cubic feet

per 1000 BTU/Hr (4.8 m3/kW). This method is to

be used if the air infiltration rate is unknown or if

the rate of air infiltration is known to be greater

than 0.6 air changes per hour. As an option, this

method may be used if the air infiltration rate is

known to be between 0.6 and 0.4 air changes per

hour. If the air infiltration rate is known to be

below 0.4 then the Known Air Infiltration Rate

Method must be used. If the building in which this

appliance is to be installed is unusually tight, PB

Heat recommends that the air infiltration rate be

determined.

b. Known Air Infiltration Rate Method

:

where:

I

fan

= Input of the fan assisted appliances

in Btu/hr

ACH = air change per hour (percent of the

volume of the space exchanged per

hour, expressed as a decimal)

Note: These calculations are not to be used for

infiltration rates greater than 0.60 ACH.

3

PREINSTALLATION

Figure 1.1: Minimum Accessibility Clearances – PF-850, PF-1000

15 ft

3

I

fan

ACH 1000

Btu

/

hr

Required Volume

fan

=

⎛

⎜

⎝

⎛

⎜

⎝

Loading...

Loading...