96

SECTION 13: Troubleshooting

13.3 Testing Submersible Motor

Insulation and Winding

Resistance

Insulation Resistance

1. Turn off power!

2. Set the ohmmeter to RX100K ohms.

3. Zero the ohmmeter.

4. Connect one lead to the metal drop pipe (or to ground

if the pipe is plastic).

5. Connect the other lead to any motor lead.

6. Check each power lead.

7. Compare results to the following table.

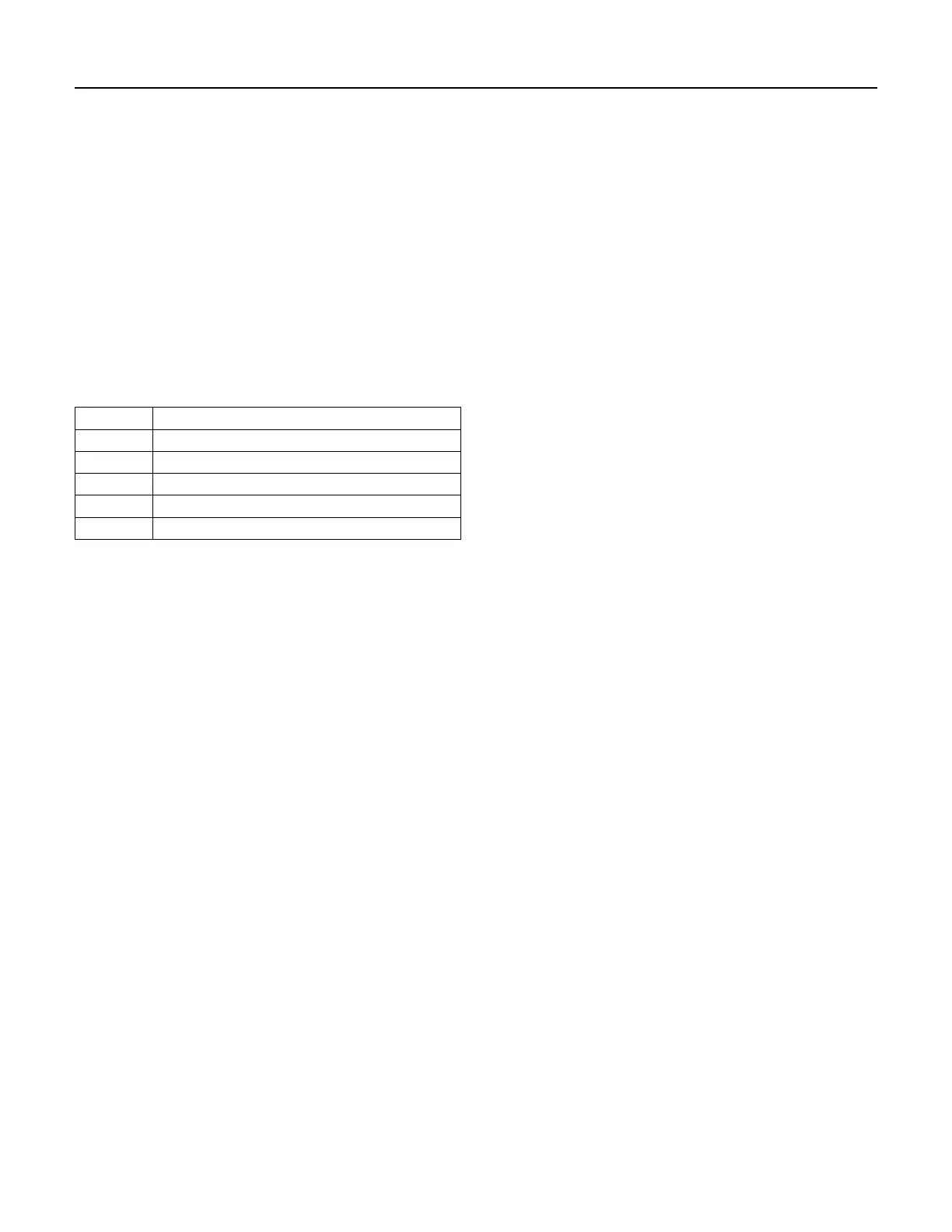

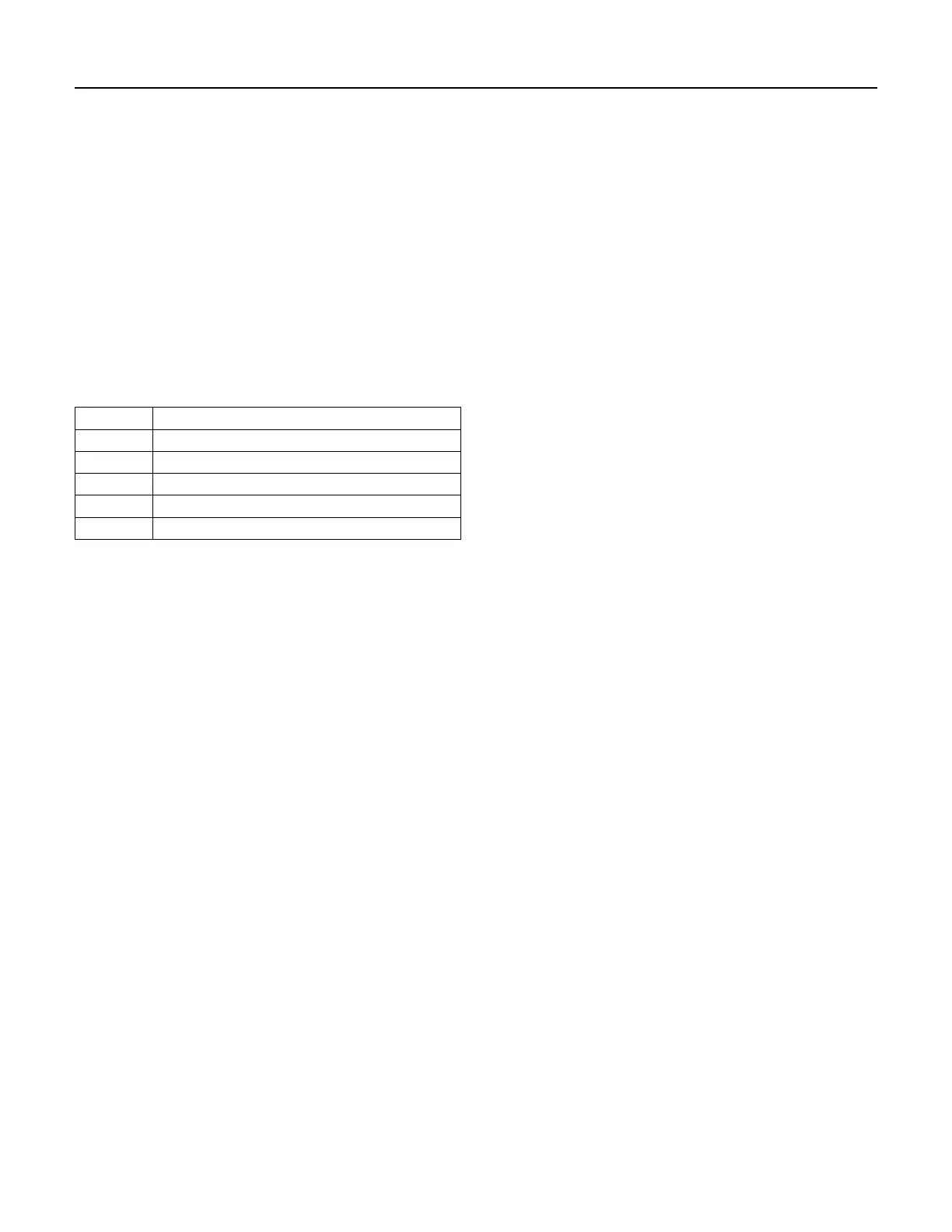

Resistance Indicates

20K ohm Damaged motor, possible result of lightning strike.

500K ohm Typical of older installed motor in well.

2 M ohm Newly installed motor

10 M ohm Used motor, measured outside of well

20 M ohm New motor without cable

Winding Resistance

1. Turn off power!

2. Set the ohmmeter to RX1 ohm range. For values over

10, use the RX10 ohm scale.

3. Zero the ohmmeter.

4. Compare results to resistance shown in motor

specifications table.

Three Phase Motors

Measure each line to each other (three readings).

Compare these to the line-to-line resistance shown in

motor specification table.

• Ifallleadsmeasurewithinthetablespecifications,

the leads and motor are okay.

• Ifaleadshowsahigherresistance,thenthereis

an open in the cable or winding. Check for secure

cableconnections.

• Ifaleadshowslowerresistance,thenthereisashort

circuit in the cable or winding.

Single Phase Motors: 3-wire

• Measurethemainwinding(blacktoyellow).

• Measurethestartwinding(redtoyellow).

• Comparethesereadingswiththemotor

specificationtable.

• Ifthereadingsvarywidely(somehigh,somelow),the

leads may be switched. Confirm that the cable colors

are correct.

Single Phase Motors: 2-wire

• Measuretheresistancebetweenthetwolines.

• Comparethereadingwiththemotor

specificationtable.

• Ifthereadingshowsahighresistance,theremay

be an open in the cable or motor. Check for secure

cableconnections.

• Ifthereadingshowsverylowresistance,theremaybe

a short in the cable or motor.

Loading...

Loading...