24

SECTION 5: XE Series 4” Submersible Motors

5.8 4” Motor Overload Protection

Single Phase Motors

Single phase motors have overload protection either

in the motor or in the control box. Motors less than or

equal to 1HP have built-in protection. This automatic

protection will continue to cycle under a locked or stalled

rotorcondition.

Single phase motors larger than 1 HP use overload

protection located in the SMC (Submersible Motor

Controls) section. These are manual overloads and must

be manually reset if an overload condition occurs.

5.9 Motor Cooling

Pentek

®

4” XE Series motors are designed to operate to a

maximum SF (Service Factor) horsepower in water up to

86° F (30° C).

4” motors: Minimum cooling water flow 3 HP and over

I.D of casing Flow GPM (LPM) required

4 1.2 (4.5

5 7 (26.5)

6 13 (49)

7 20 (76)

8 30 (114)

10 50 (189)

12 80 (303)

14 110 (416)

16 150 (568)

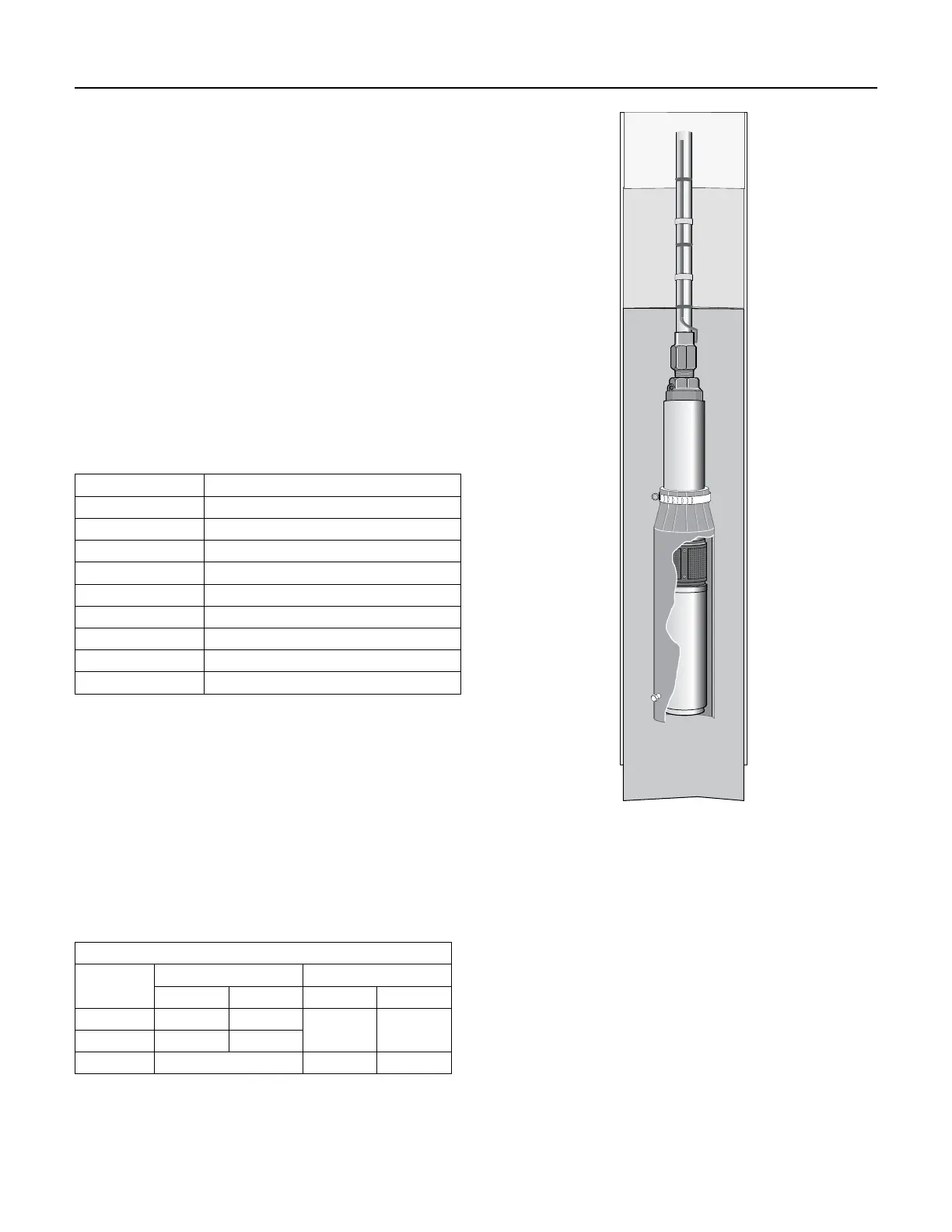

If the flow is less than specified, a flow-inducer sleeve

can be installed, as shown in Figure 5-2. The sleeve will

act like a smaller casing size to force flow around the

motor to aidcooling.

5.10 Starting Frequency

Recommended motor starting frequency is shown

below. Motor, pressure switch, tank, and pump life may

be extended by limiting starts per hour and starts per

day. Proper tank sizing is critical to control pump cycle

times. Excessive or rapid cycling creates heat which can

prematurely damage motors, switches, andcontrols.

Motor Starting Frequency

HP

Single Phase Three Phase

Starts/hr Starts/24hr Starts/hr Starts/24hr

1/2 thru 3/4 12.5 300

12.5 300

1 thru 5 4.2 100

7.5 thru 200 4.2 100

A one (1) minute minimum run time for pumps and motors up to 1.5HP and

two (2) minutes for 2HP and larger motors is recommended to dissipate heat

build-up from starting current.

Figure 5-2: Flow Inducer Sleeve

Loading...

Loading...