9

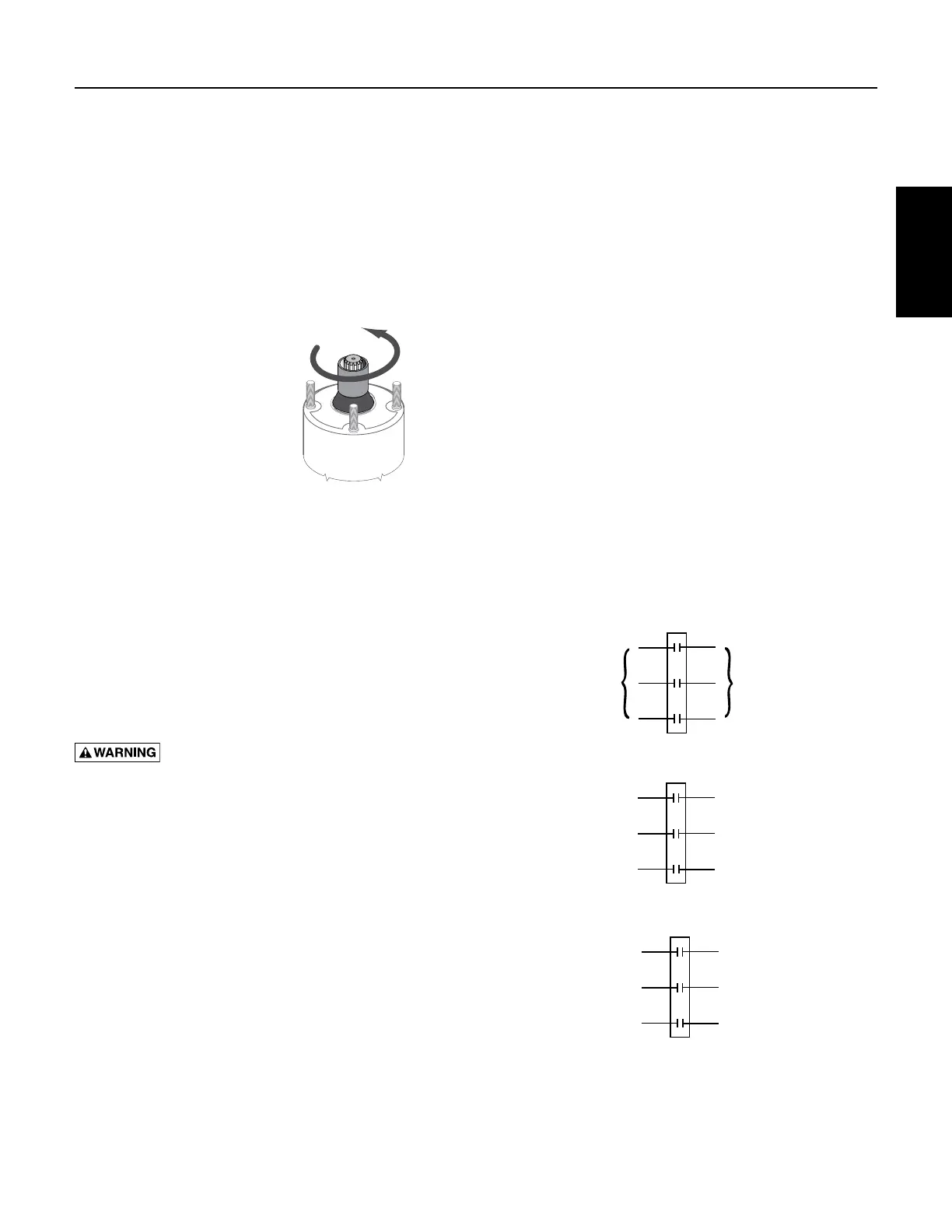

4.4 Checking Motor Rotation

To check rotation before the pump is installed, follow

thesesteps:

During testing or checking rotation (such as “bumping”

or “inching”) the number of “starts” should be limited to

3and total run time of less than 15 seconds.

Bumping must be done while motor is in horizontal

position and followed by a full 15 minute cooling-off

period before any additional “starts” are attempted.

Energize the motor

briefly, and observe the

direction of rotation.

It should be counter-

clockwise when viewed

from the pump (shaft)

end.

To check rotation after

the pump is installed:

NOTICE: NEVER

continuously operate a

pump with the discharge

valve completely closed

(dead head). This can overload the motor due to lack of

cooling, or destroy the pump and will void the warranty.

After energizing the motor, check the flow and pressure

of the pump to make sure that the motor is rotating in the

correct direction. To correct a wrong rotation, switch any

two of the three cable connections (three-phase motor

only). The setting that gives the most flow and pressure is

correct.

A cooling-off period of 15 minutes is required

betweenstarts.

Hazardous voltage. Disconnect power

before working on wiring.

Input voltage, current and insulation resistance values

should be recorded throughout the installation and

should be used for preventive maintenance.

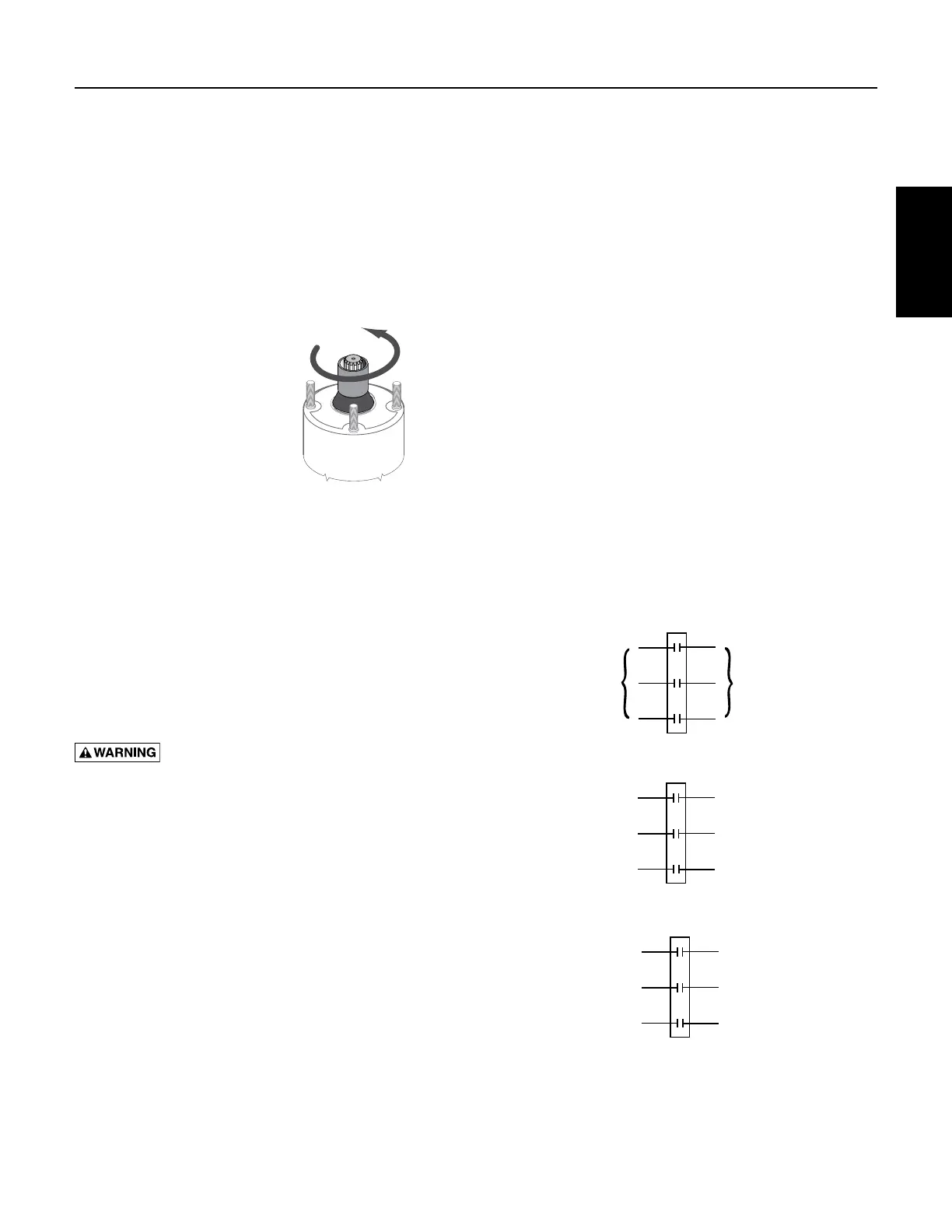

4.5 3-Phase Current Balancing

Current Unbalance Test

Before checking for current unbalance, the pump must

be started, and rotation direction determined.

Determine current unbalance by measuring current in

each power lead. Measure current for all three possible

hookups (Figure 4-11). Use example and worksheet on

the Installation Checklist and Record in Section 12 to

calculate current unbalance on a three phase supply

system and retain for future reference.

NOTICE: Current unbalance between leads should not

exceed 5%. If unbalance cannot be corrected by rolling

the leads, locate the source of the unbalance.

Here is an example of current readings at maximum

pump loads on each leg of a three wire hookup. Make

calculations for all three possible hookups.

A. For each hookup, add the readings for the three legs.

B. Divide each total by three to get average amps.

C. For each hookup, find current value farthest from

average (Calculate the greatest current difference

from the average).

D. Divide this difference by the average and multiply by

100 to obtain the percentage of unbalance.

Use smallest percentage unbalance, in this case

Arrangement 2 (Table 4.1).

Us e the Current-Balance worksheet

located in the Installation Record

After trying all three lead hookups, if the reading furthest

from average continues to show on the same power lead,

most of the unbalance is coming from the power source.

Call the power company.

If the reading furthest from average changes leads as the

hookup changes (that is, stays with a particular motor

lead), most of the unbalance is on the motor side of the

starter. This could be caused by a damaged cable, leaking

splice, poor connection, or faulty motor winding.

SECTION 4: Electrical Power

Figure 4-10: Motor Rotation

Starter

Electrical

Power

Supply

To Motor

L1

L2

L3

T1

T2

T3

Starter

L1

L2

L3

T1

T2

T3

Arrangement 1

Starter

L1

L2

L3

T1

T2

T3

Arrangement 2 Arrangement 3

Starter

Electrical

Power

Supply

To Motor

L1

L2

L3

T1

T2

T3

Starter

L1

L2

L3

T1

T2

T3

Arrangement 1

Starter

L1

L2

L3

T1

T2

T3

Arrangement 2

Starter

Electrical

Power

Supply

To Motor

L1

L2

L3

T1

T2

T3

Starter

L1

L2

L3

T1

T2

T3

Arrangement 1

Starter

L1

L2

L3

T1

T2

T3

Arrangement 2

Arrangement 3

Figure 4-11: 3-Phase Current Unbalance: Example

Electrical Power

Loading...

Loading...