104

SECTION 14: Appendix

EXAMPLE

Assume we want 16 GPM at 60 PSI from a pump

drawdown level (pumping level) 100 feet below the

serviceinlet.

We have a 35 foot horizontal run of 1 1/4” plastic pipe

with two gate valves and four 90° elbows.

To find the Friction losses we must refer to friction loss

charts for pipe and fittings.

We find:

• 135feetofpipeforthetotalpiperun(100+35).

• 10equivalentfeetofpipeforthegatevalves(2x5)

• 28equivalentfeetofpipefortheelbows(7x4)

Add these for the total equivalent length of pipe = 173

• Inthefrictionlosscharts,findthelossofheadfor

173feet of 1 1/4” pipe at 16 gpm. (3.96 per 100’) =3.96

x 1.73 = 6.8 (round to 7.0)

Add: 7 Friction loss

100 Pumping level

139 60 PSI service pressure required (60

x2.31=138.6. Round to 139)

= 246 Total Dynamic Head.

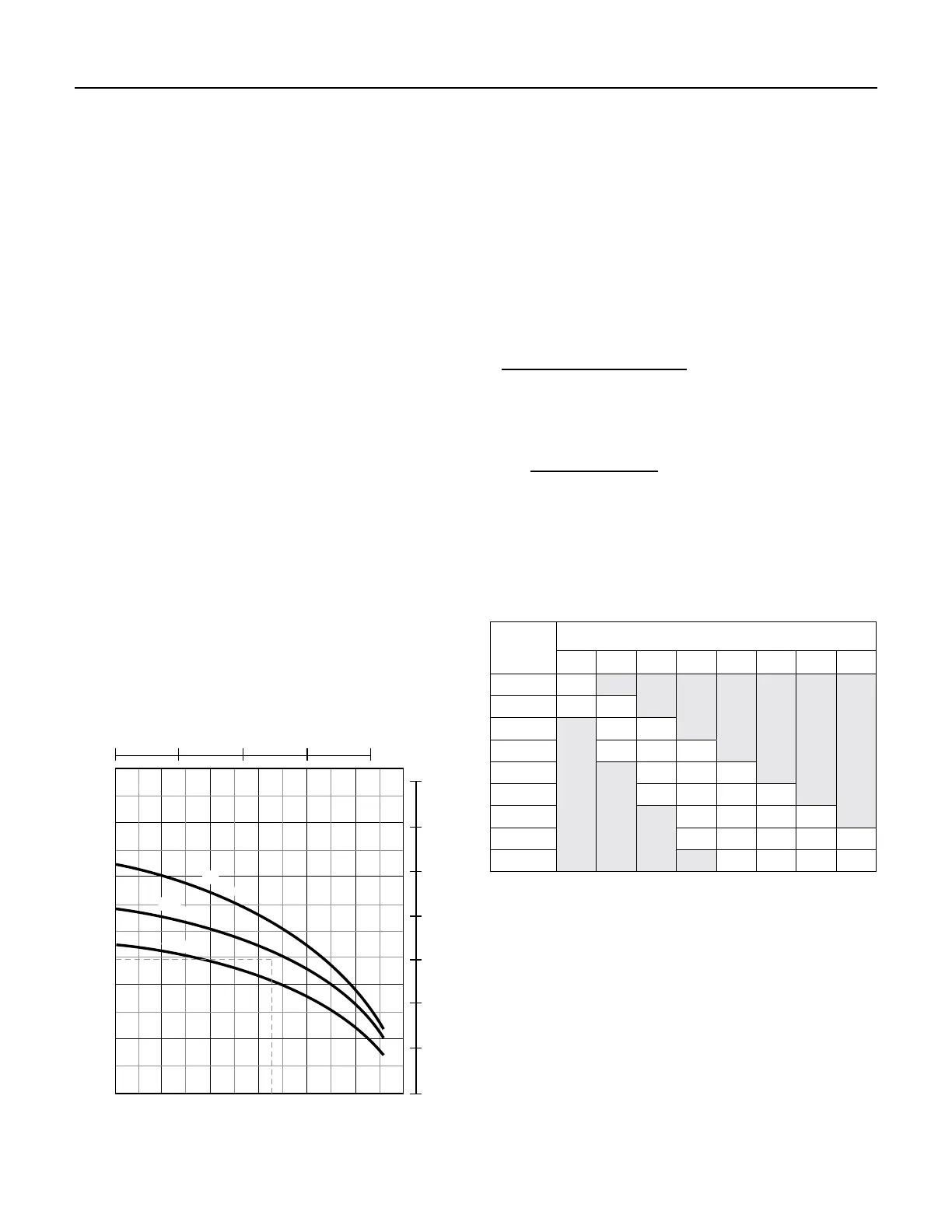

From this sample curve we would choose the

11/2HPpump.

Locate a pump with a best efficiency point near the

desired flow rate (16 GPM) that meets the total head

requirements (246 TDH).

Selecting a pump in this manner gives you the most

efficient pump for your application.

14.5 Sizing Tanks

Tank should be sized to accomodate starting frequency in

Section 5.10.

Refer to the dealer catalog for tank selection. Otherwise,

the following procedure can be used.

Drawdown based on Boyle’s Law

Procedure:

1. Identify drawdown multiplier relating to

specific application.

2. Insert multiplier (X) into the following formula:

Pump GPM x Min Run Time = Minimum Tank

Multiplier (X) Capacity Required

Example: An example of a 20 GPM pump with a

minimum run time of 1 minute, installed on a

50-70 PSIG system pressure range:

20 GPM x 1 minute = 83.3 minimum U.S.

.24 (factor) gallon tank capacity

NOTICE: Drawdown will be affected by operating

temperature of the system, accuracy of the pressure

switch and gauge, the actual pre-charge pressure and the

rate offill.

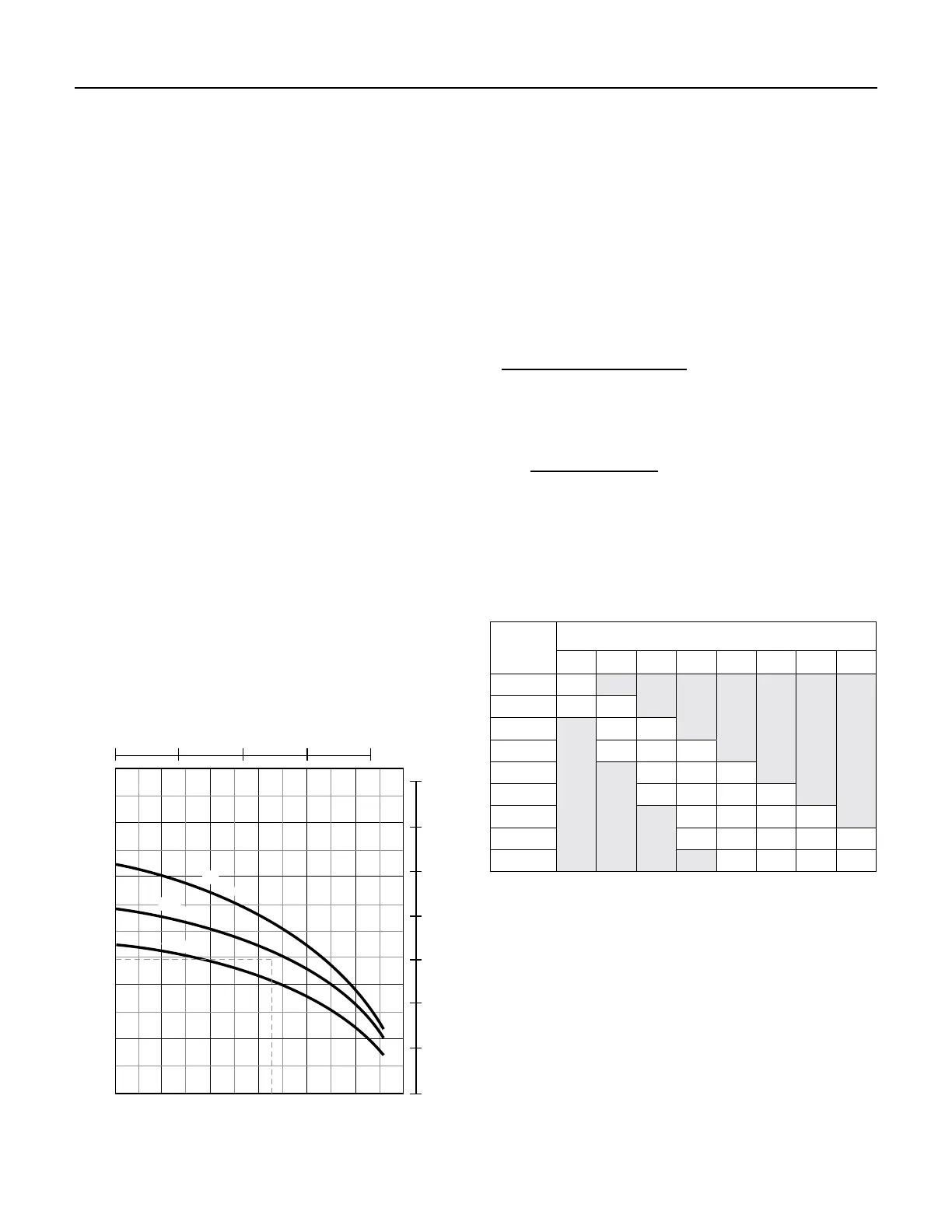

Table 12-2: Drawdown Volume Multiplier

(Approximate)

Pump Off

Pressure

PSI

Pump Start Pressure –PSI

10 20 30 40 50 60 70 80

20 0.26

30 0.41 0.22

40 0.37 0.18

50 0.46 0.31 0.15

60 0.40 0.27 0.13

70 0.47 0.35 0.24 0.12

80 0.42 0.32 0.21 0.11

90 0.48 0.38 0.29 0.19 0.10

100 0.44 0.35 0.26 0.17

Ta nk sizing for Variable Frequency Drives

Variable Frequency Drives (VFD) may require slightly

different methods for figuring tank size. Refer to

Section 8 for VFD information.

Sample Pump Curve

600

500

400

300

200

100

0 20 10 5 25 30 15

1 HP

1-1/2 HP

2 HP

CAPACITY GALLONS PER MINUTE

CAPACITY LITRES PER MINUTE

TOTAL HEAD IN METERS

25 0 50 75 100

175

150

125

100

75

50

25

0

Loading...

Loading...