2. Maintain the coolant level at the maximum mark

that is correct for your application. If the engine is

equipped with a sight glass, maintain the coolant

level to the correct level in the sight glass.

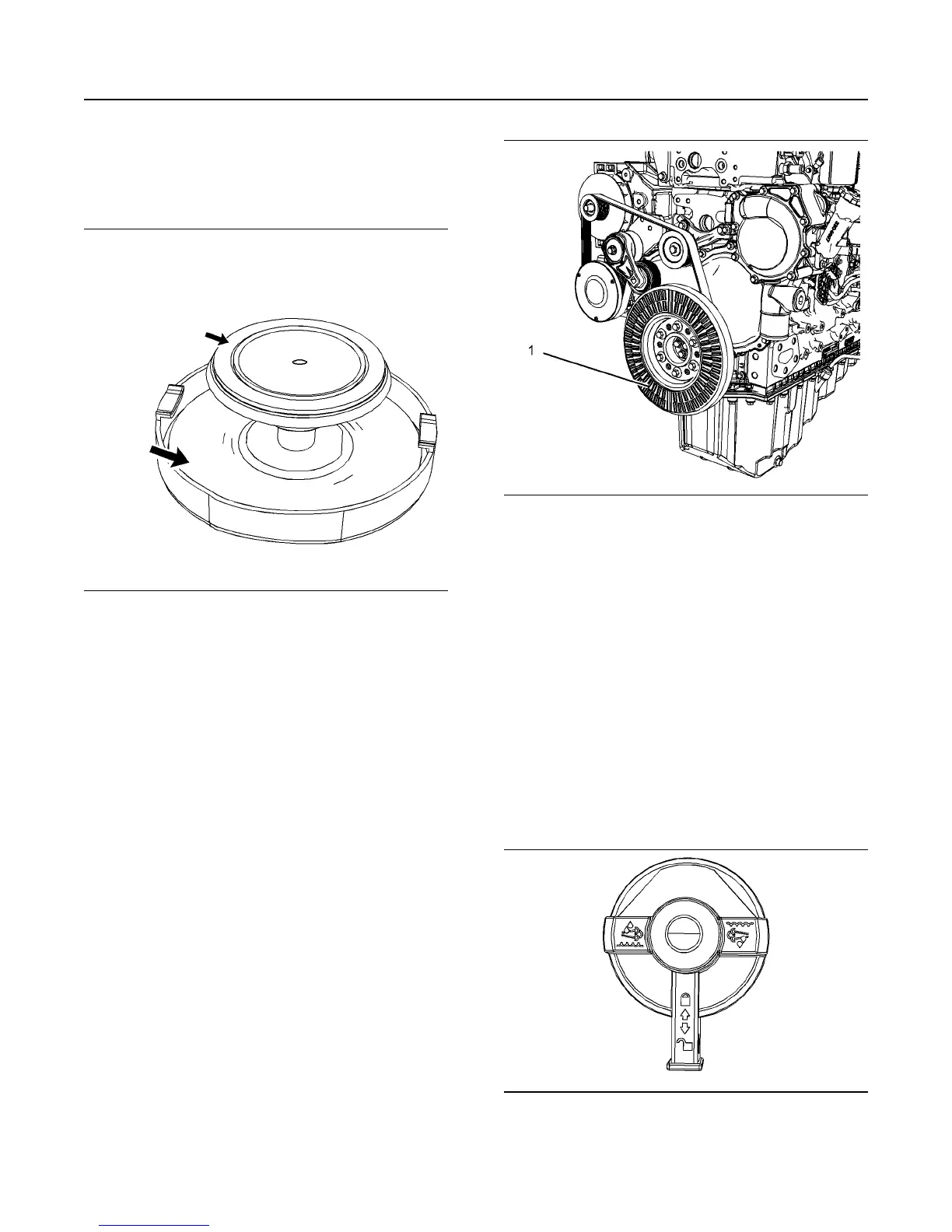

Illustration 67 g02590196

Typical filler cap gaskets

3. Clean the cooling system filler cap and check the

condition of the filler cap gaskets. Replace the

cooling system filler cap if the filler cap gaskets are

damaged. Reinstall the cooling system filler cap.

4. Inspect the cooling system for leaks.

Note: The Diesel Exhaust Fluid (DEF) tank requires

coolant flow around the tank. The Coolant Diverter

Valve (CDV) will turn the flow on or off. If the coolant

system has been filled with the CDV in the closed

position, coolant level will drop because of the

opening of the CDV.

i03634651

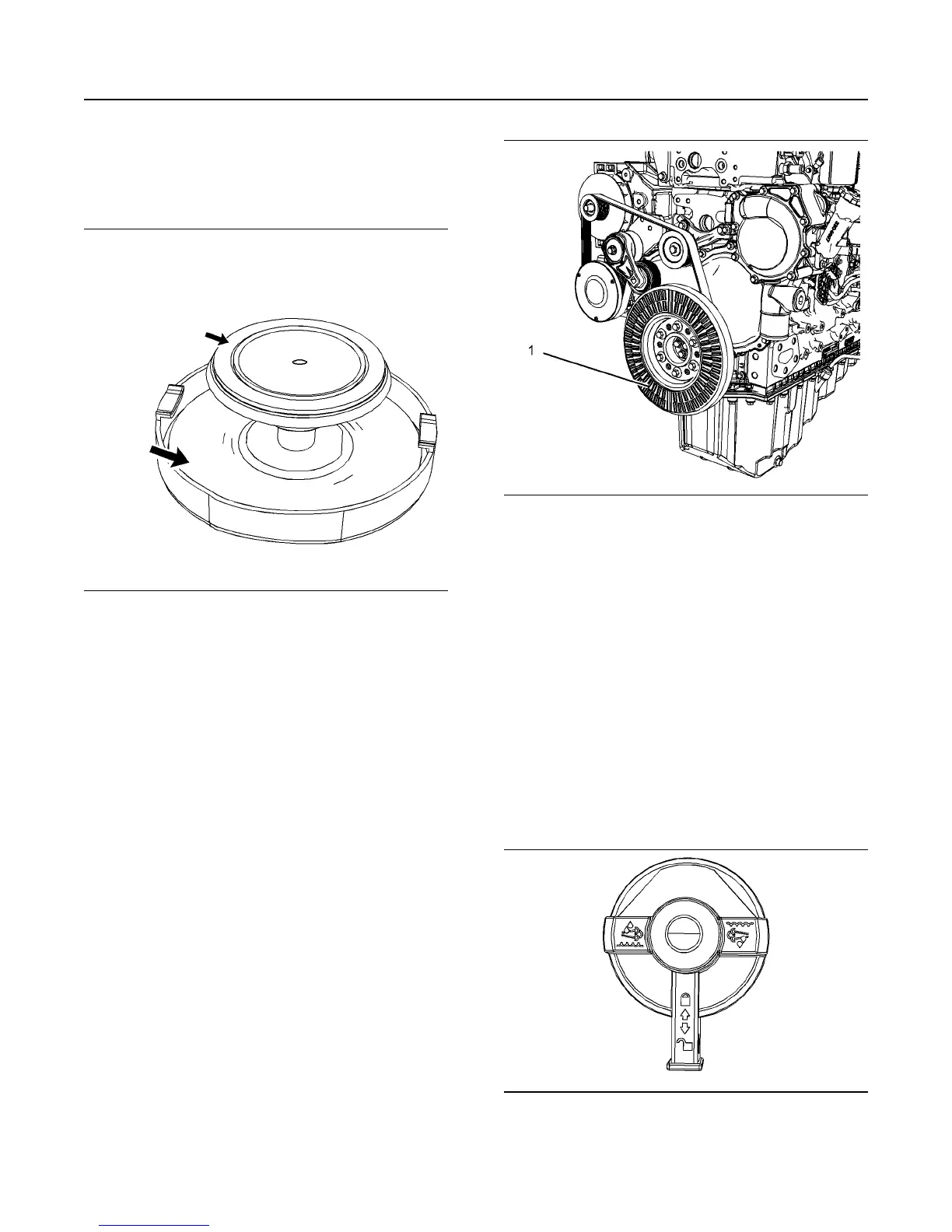

Crankshaft Vibration Damper -

Inspect

Viscous Damper

The viscous damper has a inertia weight that is

located inside a fluid filled case. The inertia weight

moves in the case in order to limit torsional vibration.

Visually inspect the crankshaft damper. Ensure that

the cooling fins (1) on the crankshaft damper are

clean and free from dirt.

Illustration 68 g01950241

Typical example

Inspect the damper and replace the damper for any of

the following reasons:

• The damper is dented, cracked, or leaking.

For information on removal of the crankshaft damper,

refer to Disassembly and Assembly, “Vibration

Damper and Pulley - Remove and Install”.

i05413412

Diesel Exhaust Fluid - Fill

Refer to the original equipment manufacture

information for the Diesel Exhaust Fluid (DEF) tank

capacity.

Illustration 69 g03379943

Lockable type DEF Filler cap

100 SEBU8732

Maintenance Recommendations

Crankshaft Vibration Damper - Inspect

Loading...

Loading...