i05424317

Battery or Battery Cable -

Disconnect

The battery cables or the batteries should not be

removed with the battery cover in place. The bat-

tery cover should be removed before any servic-

ing is attempted.

Removing the battery cables or the batteries with

the cover in place may cause a battery explosion

resulting in personal injury.

1. Turn the start switch to the OFF position. Turn the

ignition switch (if equipped) to the OFF position

and remove the key and all electrical loads.

Note: After the engine has stopped, allow 2 minutes

in order for the diesel exhaust fluid lines to be purged

before disconnecting the power.

2. Disconnect the negative battery terminal. Ensure

that the cable cannot contact the terminal. When

four 12 V batteries are involved, 2 negative

connections must be disconnected.

3. Remove the positive connection.

4. Clean all disconnected connection and battery

terminals.

5. Use a fine grade of sandpaper to clean the

terminals and the cable clamps. Clean the items

until the surfaces are bright or shiny. DO NOT

remove material excessively. Excessive removal of

material can cause the clamps to fit incorrectly.

Coat the clamps and the terminals with a suitable

silicone lubricant or petroleum jelly.

6. Tape the cable connections in order to help prevent

accidental starting.

7. Proceed with necessary system repairs.

8. In order to connect the battery, connect the positive

connection before the negative connector.

i04907925

Belt Tensioner - Check

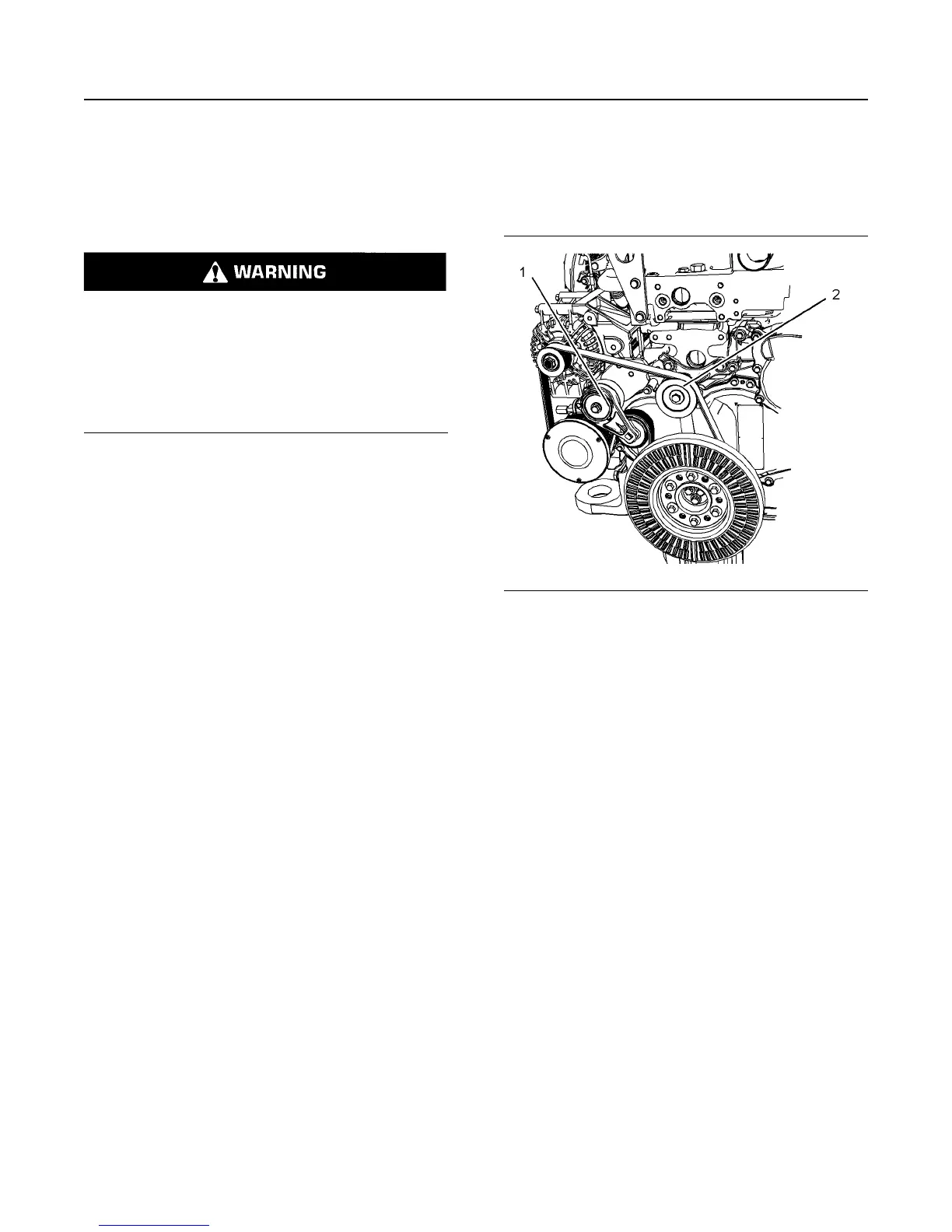

Illustration 60 g03074016

Typical example

Remove the belt. Refer to Disassembly and

Assembly, “Alternator Belt - Remove and Install”.

Ensure that the belt tensioner is securely installed.

Visually inspect the belt tensioner (1) for damage.

Check that the pulley on the tensioner rotates freely

and that the bearing is not loose. Some engines have

an idler pulley (2). Ensure that the idler pulley is

securely installed. Visually inspect the idler pulley for

damage. Ensure that the idler pulley can rotate freely

and that the bearing is not loose. If necessary,

replace damaged components.

Install the belt. Refer to Disassembly and Assembly,

“Alternator Belt - Remove and Install”.

94 SEBU8732

Maintenance Recommendations

Battery or Battery Cable - Disconnect

Loading...

Loading...