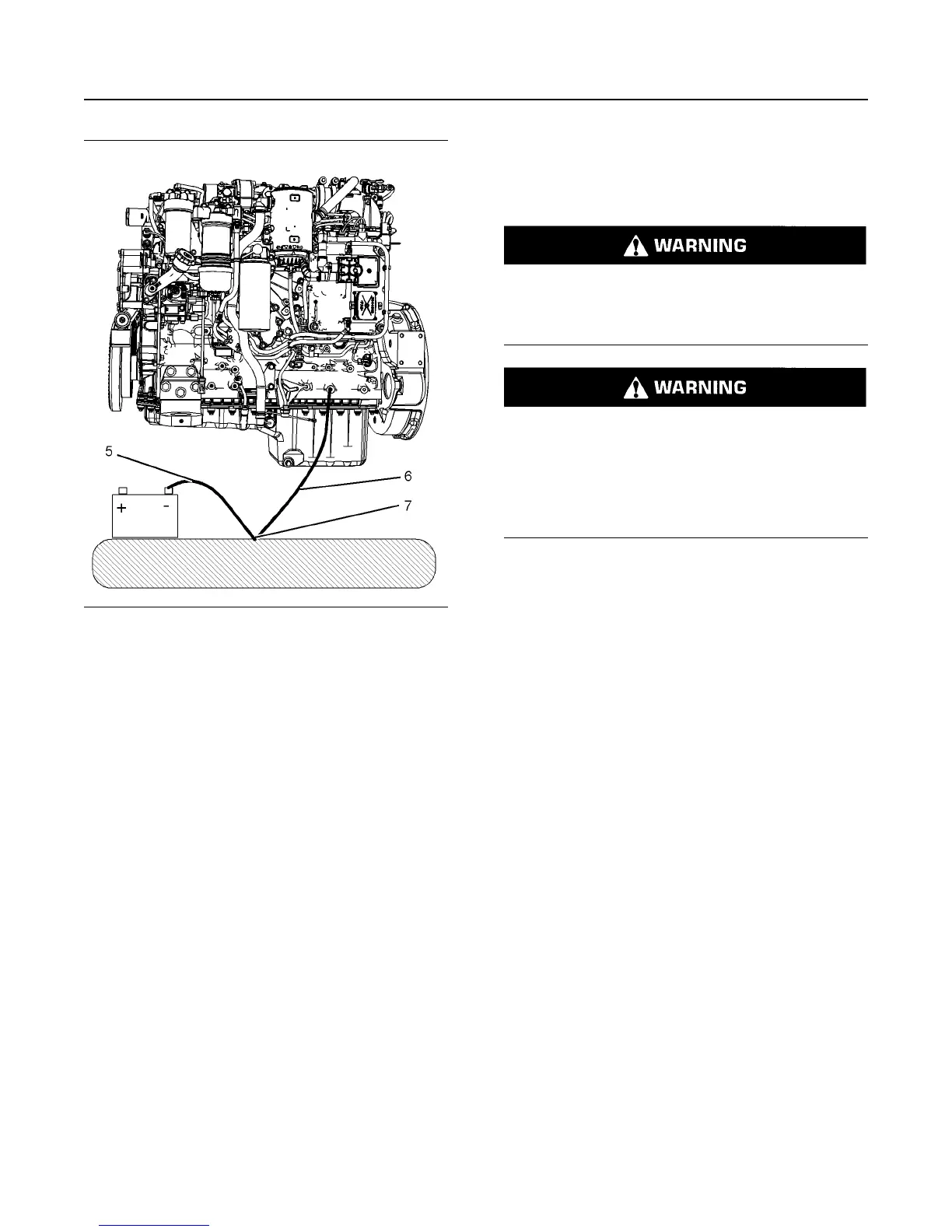

Illustration 14 g03027396

Typical example

(5) Ground to the battery

(6) Ground to the engine block

(7) Primary position for grounding

Correct grounding for the engine electrical system is

necessary for optimum engine performance and

reliability. Incorrect grounding will result in

uncontrolled electrical circuit paths and in unreliable

electrical circuit paths.

Uncontrolled electrical circuit paths can result in

damage to the crankshaft bearing journal surfaces

and to aluminum components.

Engines that are installed without engine-to-frame

ground straps can be damaged by electrical

discharge.

To ensure that the engine and the engine electrical

systems function correctly, an engine-to-frame

ground strap with a direct path to the battery must be

used. This path may be provided by way of a direct

engine ground to the frame.

The connections for the grounds should be tight and

free of corrosion. The engine alternator must be

grounded to the negative “-” battery terminal. The

wire used must be adequate to handle the full

charging current of the alternator.

The power supply connections and the ground

connections for the engine electronics should always

be from the isolator to the battery.

i05192488

Engine Electronics

Tampering with the electronic system installation

or the OEM wiring installation can be dangerous

and could result in personal injury or death and/or

engine damage.

Electrical Shock Hazard. The electronic unit injec-

tors use DC voltage. The ECM sends this voltage

to the electronic unit injectors. Do not come in

contact with the harness connector for the elec-

tronic unit injectors while the engine is operating.

Failure to follow this instruction could result in

personal injury or death.

This engine has a comprehensive, programmable

Engine Monitoring System. The Electronic Control

Module (ECM) monitors the engine operating

conditions. If any of the engine parameters extend

outside an allowable range, the ECM will initiate an

immediate action.

The following actions are available for engine

monitoring control:

• Warning

• Derate

• Shutdown

The following monitored engine operating conditions

and components can limit engine speed and/or the

engine power:

• Engine Coolant Temperature

• Engine Oil Pressure

• Engine Speed

• Intake Manifold Air Temperature

• Wastegate Regulator

• Supply Voltage to Sensors

• Fuel Temperature

• Fuel Pressure in Manifold (Rail)

• NOxReduction System

• Engine Aftertreatment System

18 SEBU8732

Safety Section

Engine Electronics

Loading...

Loading...