For more information on DEF, refer this Operation and

Maintenance Manual, “Fluid Recommendations”.

Engine Specifications

Note: The front end of the engine is opposite the

flywheel end of the engine. The left and the right

sides of the engine are determined from the flywheel

end. The number 1 cylinder is the front cylinder.

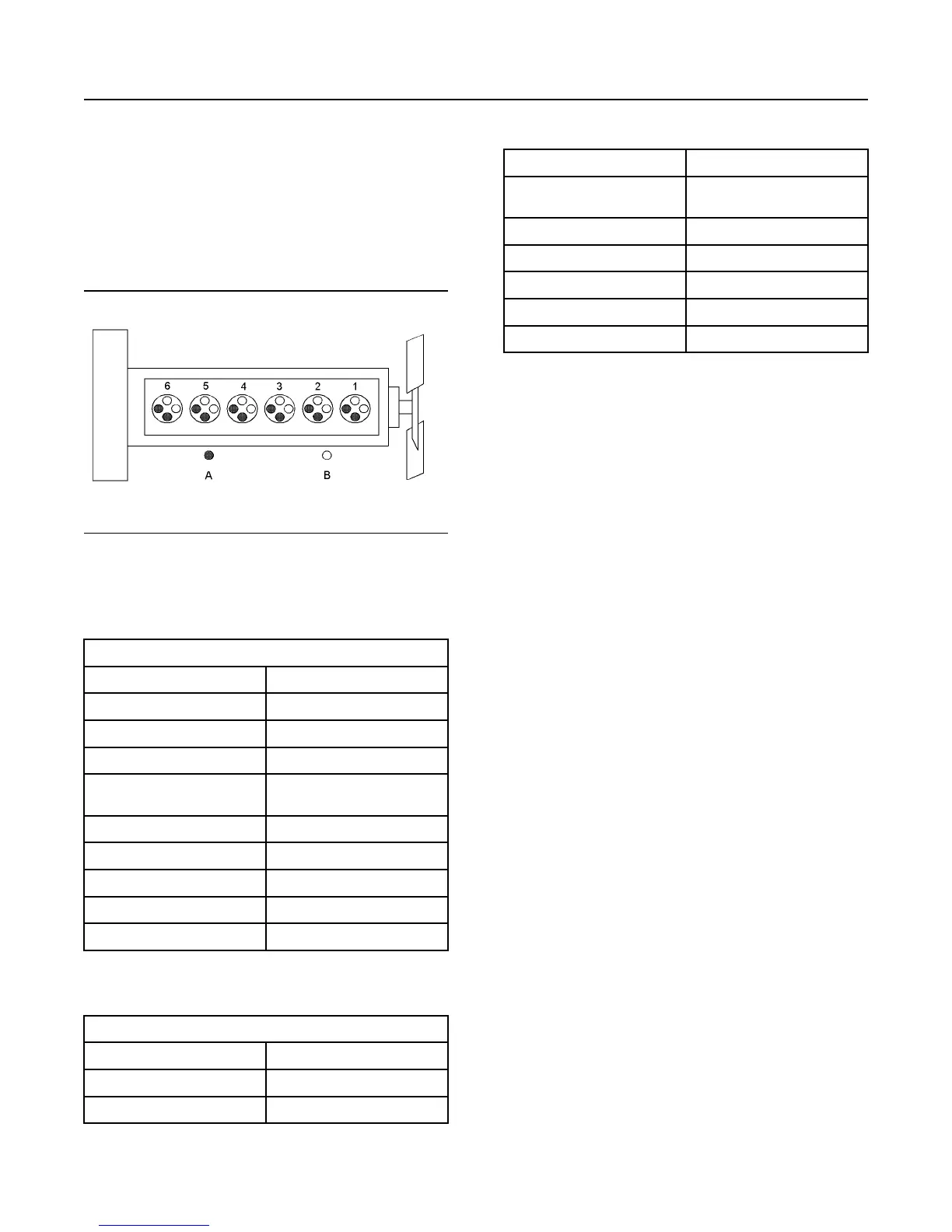

Illustration 22 g01127295

Cylinder and valve location

(A) Exhaust valves

(B) Inlet valves

Table 1

1206F-TA Single Turbocharged Engine Specifications

Operating Range (rpm)

900 to 2800

(1)

Number of Cylinders

6 In-Line

Bore 105 mm (4.13 inch)

Stroke 127 mm (5 inch)

Power

116 to 151 kW

(155.5 to 202.5 hp)

Aspiration Turbocharged charge cooled

Compression Ratio

16.4:1

Displacement 7.01 L (428 in

3

)

Firing Order

1-5-3-6-2-4

Rotation (flywheel end)

Counterclockwise

(1)

The operating rpm is dependent on the engine rating, the appli-

cation, and the configuration of the throttle.

Table 2

1206F-70TTA Series Turbocharged Engine Specifications

Operating Range (rpm)

900 to 2800

(1)

Number of Cylinders

6 In-Line

Bore 105 mm (4.13 inch)

(continued)

(Table 2, contd)

Stroke 135 mm (5.31495 inch)

Power

151 to 205 kW

(202.5 to 274.9 hp)

Aspiration Turbocharged charge cooled

Compression Ratio

16.4:1

Displacement 7.01 L (428 in

3

)

Firing Order

1-5-3-6-2-4

Rotation (flywheel end)

Counterclockwise

(1)

The operating rpm is dependent on the engine rating, the appli-

cation, and the configuration of the throttle.

Electronic Engine Features

The engine and aftertreatment operating conditions

are monitored. The Electronic Control Module (ECM)

controls the response of the engine to these

conditions and to the demands of the operator. These

conditions and operator demands determine the

precise control of fuel injection by the ECM. The

electronic engine control system provides the

following features:

• Engine monitoring

• Engine speed governing

• Control of the injection pressure

• Cold start strategy

• Automatic air/fuel ratio control

• Torque rise shaping

• Injection timing control

• System diagnostics

• NOx reduction system control

• Aftertreatment system control

The ECM provides an electronic governor that

controls the injector output in order to maintain the

desired engine speed.

For more information on electronic engine features,

refer to the Operation and Maintenance Manual,

“Features and Controls” topic (Operation Section).

Engine Diagnostics

The engine has built-in diagnostics in order to ensure

that the engine systems are functioning correctly. The

operator will be alerted to the condition by a “Stop or

Warning” lamp. Under certain conditions, the engine

horsepower and the vehicle speed may be limited.

The electronic service tool may be used to display the

diagnostic codes.

SEBU8732 27

General Information

Product Description

Loading...

Loading...