Back Bar Service Manual

Return to Table of Contents Refrigeration System Repair Instructions Page 6-8

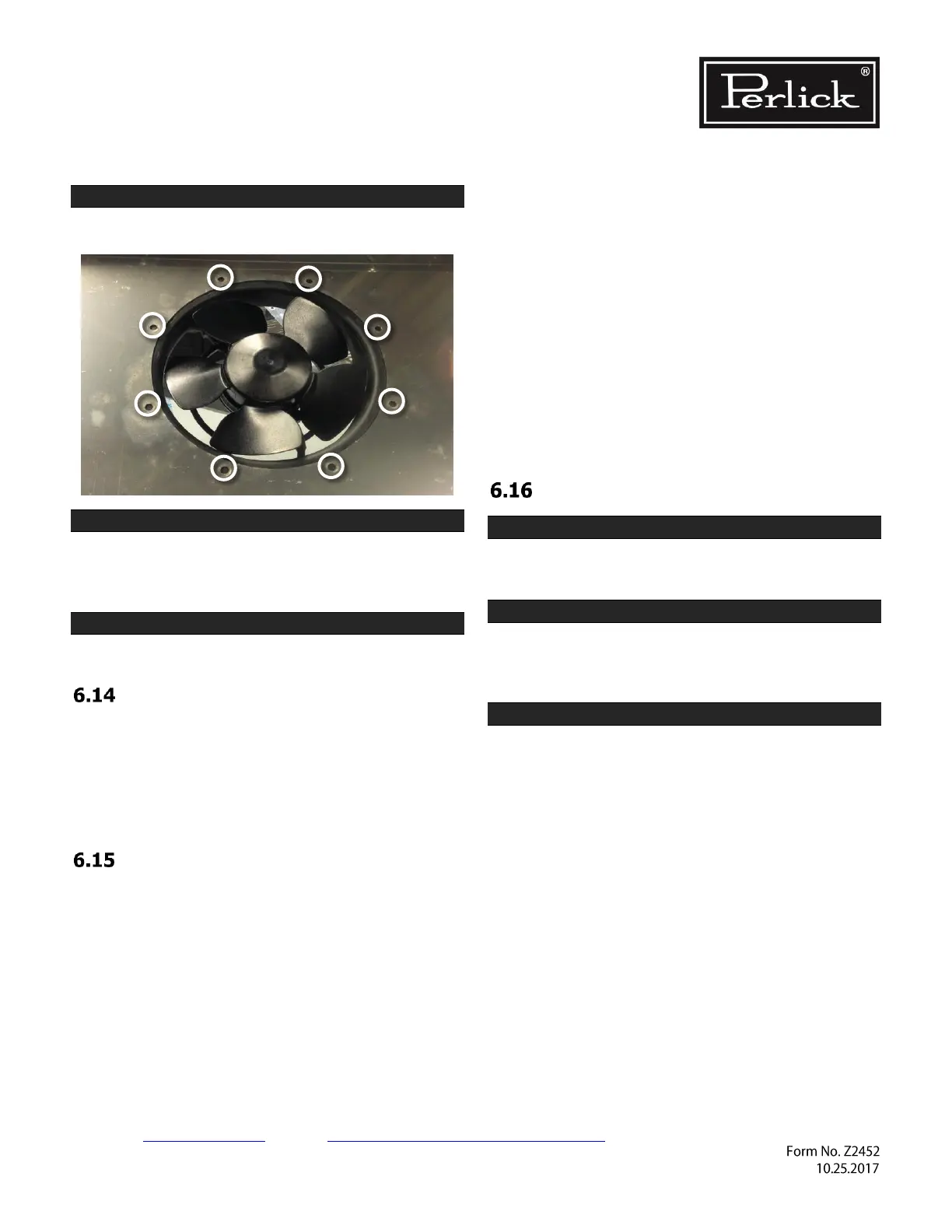

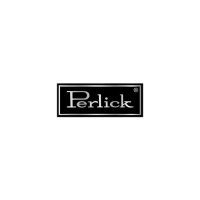

STEP 9.

Remove 8 fan mounting screws.

STEP 10.

Evaporator fan motor can now be replaced.

Evaporator fan motor should only be replaced with

Perlick OEM parts.

STEP 11.

Reverse steps 1-9 to close the unit.

Replace Compressor

To gain access to compressor, follow instructions

in Section 6.2.

Compressor should only be replaced with Perlick

OEM parts.

Always replace drier when replacing compressor.

Leak Detection

If during a check of operating system pressures, it

is determined that refrigerant level is low, you

must perform a leak test.

• Do not recharge a system without first

determining where original refrigerant charge

exited the sealed system!

• Placing a system that has lost refrigerant

under a vacuum without first repairing the

leak will draw contaminants into the system

through the point of leak. Find source of the

leak and correct it!

• The use of an electronic leak detector is

highly encouraged.

• If the entire charge has leaked out of the

unit, the sealed system should be pressurized

with 200 lbs. of dry nitrogen and tracer

refrigerant. Then use an ultrasonic leak

detector or a soap and water solution to

pinpoint the location of the leak.

• Be certain to check all brazed connections

thoroughly for leaks. Look for spots where

the sealed system components might have

been worn through by structural or cabinet

components.

• Check the service ports thoroughly for leaks

as well.

Recharge Procedure

STEP 1.

Check that the system been properly installed,

pressure tested, and evacuated.

STEP 2.

Condenser and evaporator must be clean.

Evaporator fan and condenser fan blades must be

able to move the correct amount of air.

STEP 3.

Before installing gauges, vent hoses and manifold

with refrigerant type used in unit. This avoids

introduction of air into system.

Continue to next page…

Loading...

Loading...