LiquidWatch Installation Manual

19

3.6 PHLR Hydrocarbon Probe

The PHLR series is a reusable hydrocarbon probe that detects hydrocarbon liquids in sumps, interstitial

spaces of pipes and any other areas where hydrocarbon liquids can accumulate to a depth of ¼”. The

probe is designed to detect fuels (gasoline, diesel fuel, jet fuel, crude oil, etc.) and many hydrocarbon

solvents. The probe is reusable by cleaning or replacing the sensor elements. There are 2 models of

the PHLR probe available:

The standard PHLR is designed for non-pressurized locations such as sumps, manholes, and non-

pressurized containments. The PHLR can be installed in any orientation – vertical or horizontal.

The PHLR-P is designed for pressurized containment applications. This model is ideal for typical

sealed, containment piping systems which are maintained under pressure with a nitrogen or air

blanket. The PHLR-P should be installed in a vertical orientation. The PHLR-P has vent holes that

must not be submerged in a liquid before the containment is pressurized (see Figure 10).

An extension to the probe housing can easily be added with standard ¾” Schedule 40 PVC pipe to

accommodate installation requirements.

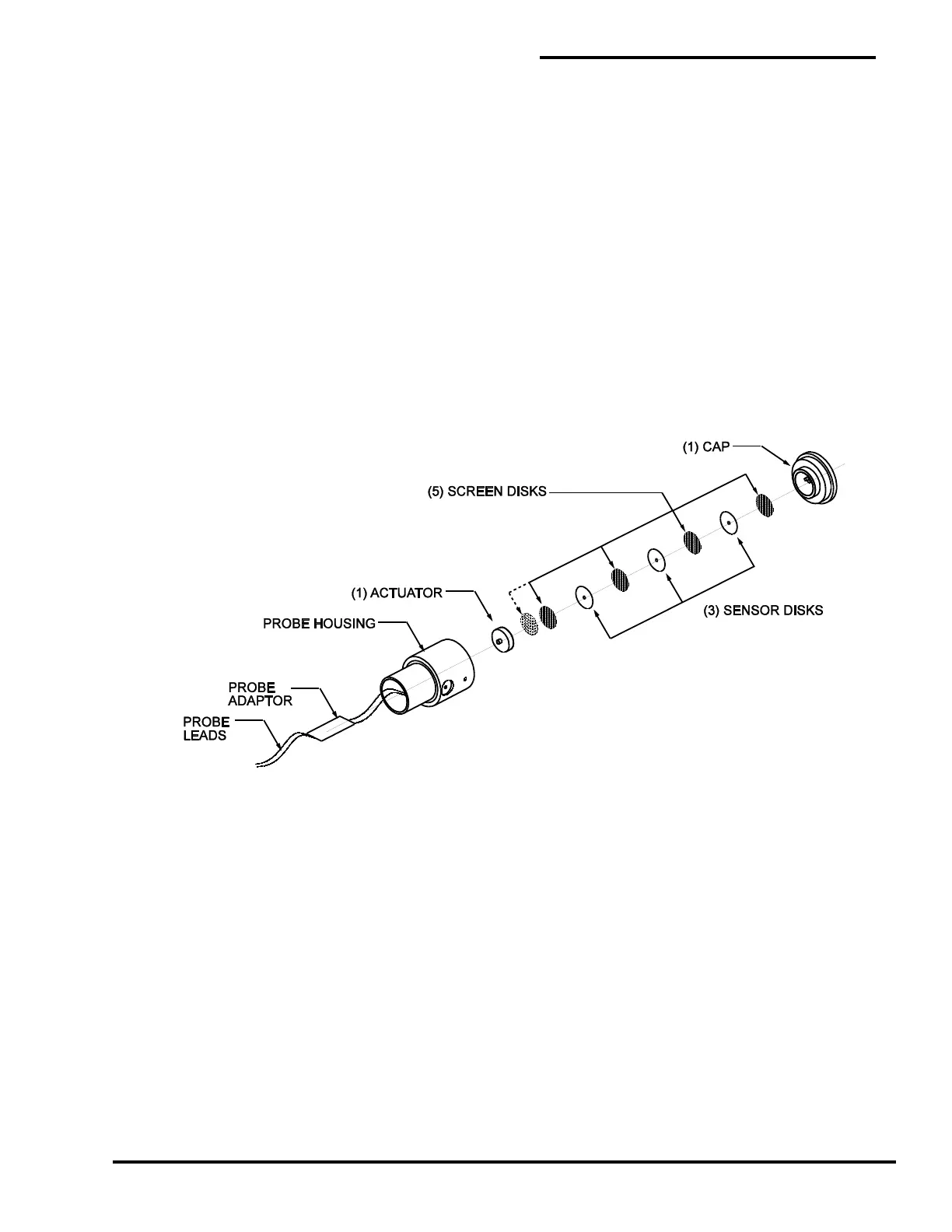

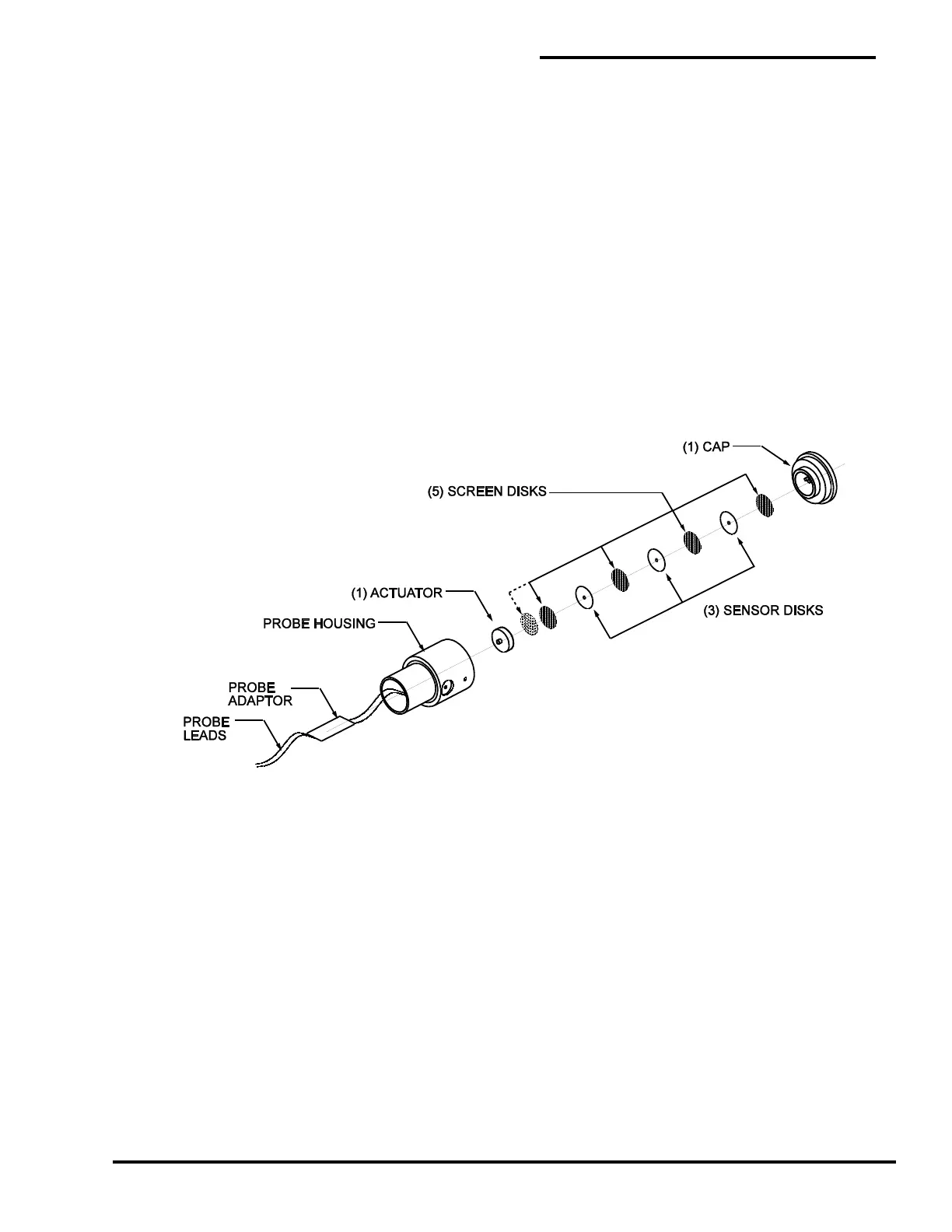

Figure 15

PHLR Sensor Package

3.6.1 Cleaning Sensor Elements Procedure

The replacement sensor package consists of 8 disks: 5 screen disks and 3 sensor disks as shown in

Figure 15. The replacement package includes all removable parts: probe cap, sensor elements, and

actuator. Replacement sensor elements only can also be purchased.

The following procedure is a general guideline to follow to clean the probe and sensor elements after

exposure to hydrocarbon liquids. Caution: It is the user’s responsibility to determine safety

precautions and the suitability of exposing personnel to the hydrocarbon liquid on the probes

and various cleaning solvents suggested.

The sensor disks swell after exposure to fuels and solvents. The swelling forces the actuator to move

and operate a low-force sealed switch. Volatile hydrocarbon liquids, such as gasoline, will eventually

evaporate after a period of time resulting in the sensor disks returning to their original size. This allows

the switch to return to the normal position. A faster resetting process is to disassemble the probe to

speed the evaporation of the liquid. Other liquids such as diesel fuel and jet fuel, which do not

Loading...

Loading...