Instruction manual for use and maintenance

for WM1L/S WM1L/S-M WM1L/E Single

head machines

File: 1927.doc - 25/01/02 11:55

14

4. COMMISSIONING

4.1 Transport

The welding machines type UNIVER are shipped fully greased and wrapped in heat-shrink

nylon.

The sturdy design and form of the machines guarantee their safe and damage-free shipment

and storage.

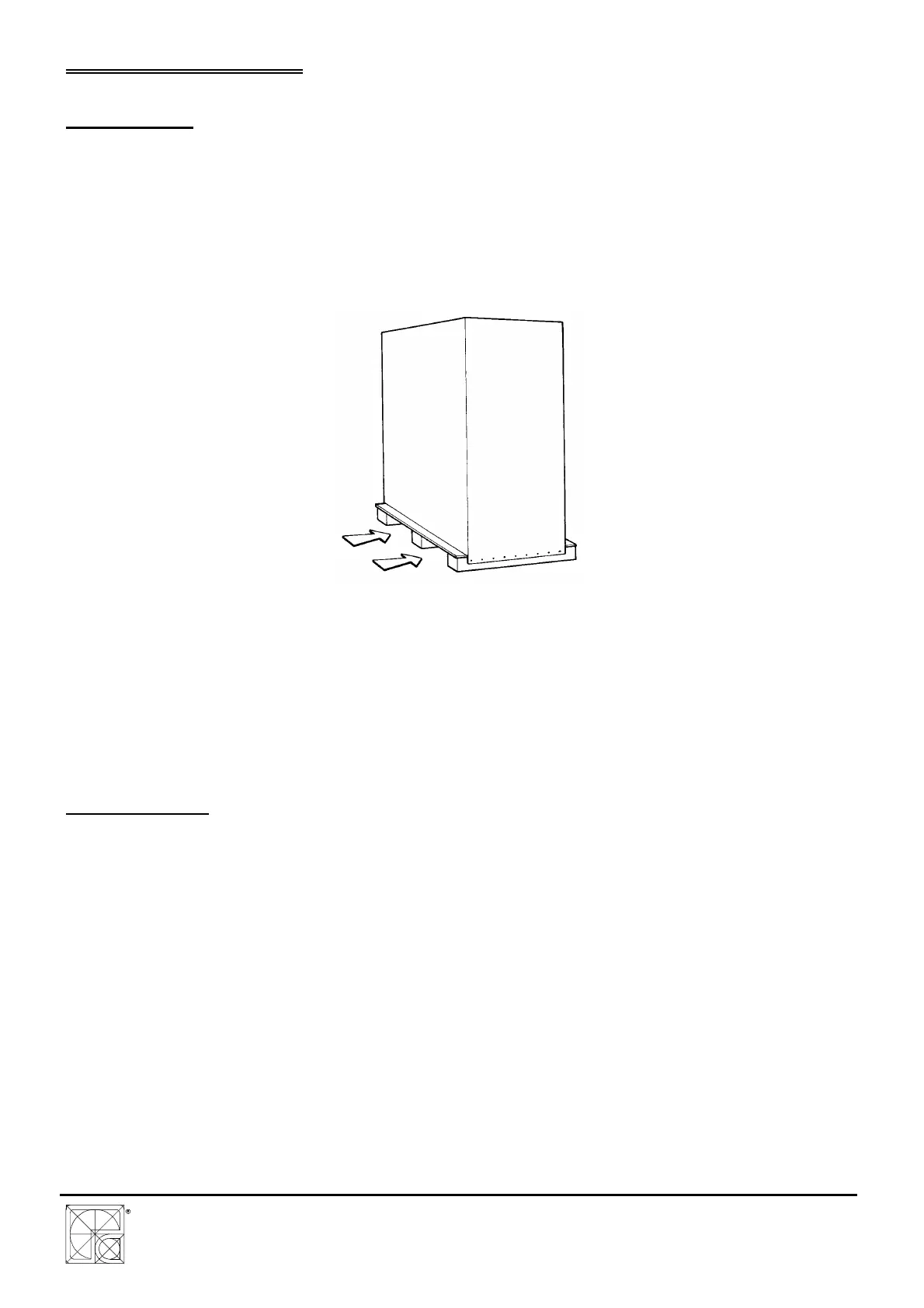

A forklift truck can lift the machines by inserting the forks at the points marked on the machine

packaging (DWG. A1.9).

DWG. A1.9

If the machine is packed in a wooden crate, the fork insertion points are marked on the crate

itself.

Take great care when performing these operations in order to avoid injury to persons and

damage to the machine or property.

4.2 Positioning

The machine must be positioned on a stable floor. Do not install the machine near to areas

containing gas or flammable substances, as the sparks and glowing fragments produced and

scattered may cause explosions or fires.

Position the machine in a place that is easily accessible for the various works and various

hook-ups to:

1) The electric equipment.

2) The compressed air circuit.

Make sure the lighting is adequate for the whole machine

Remove the machine from its packaging and make sure it has incurred no damage during

shipment.

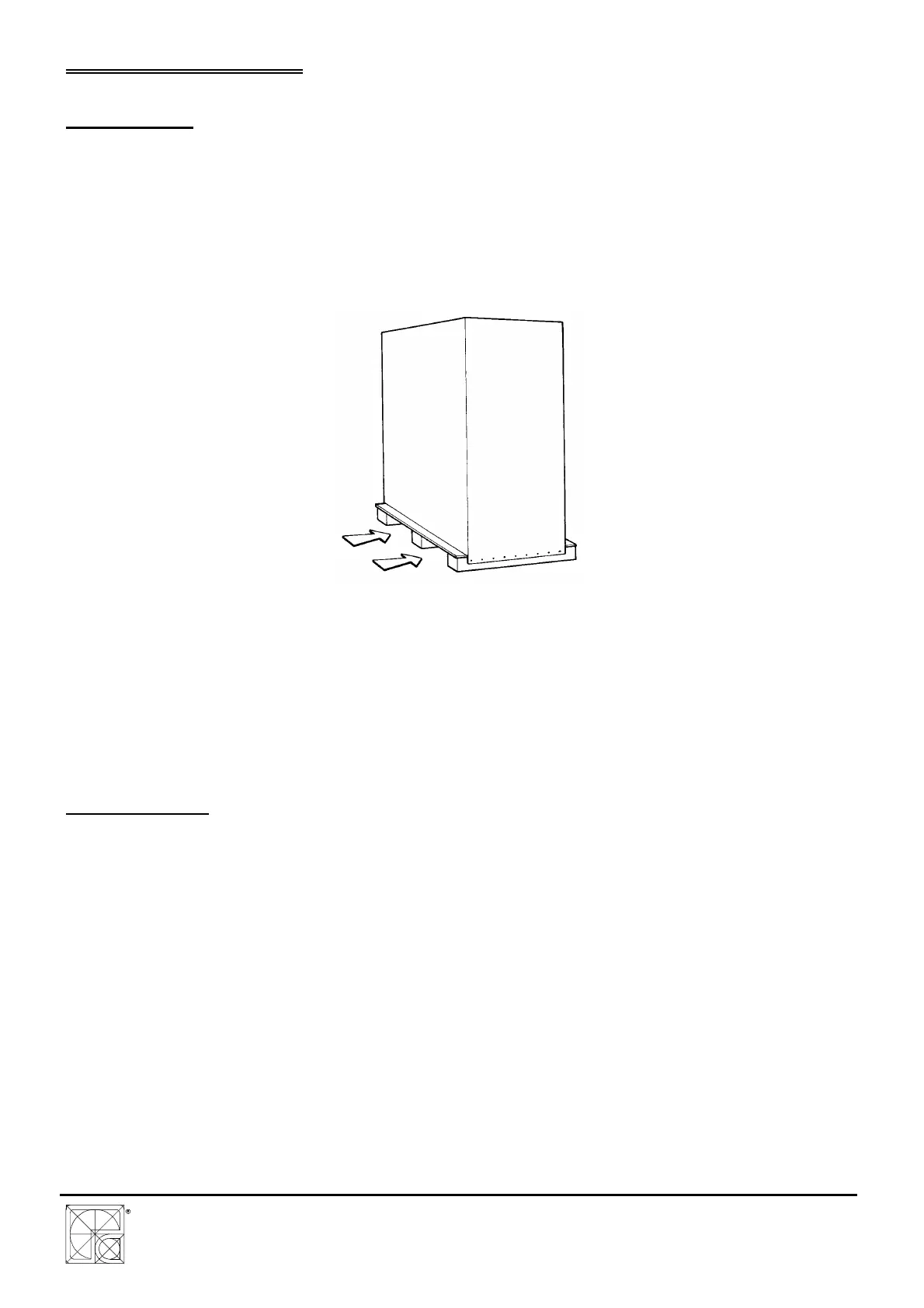

Remove the packaging: a forklift truck can now lift the machine. If transferred by forklift truck,

the forks must be inserted in the lower part of the base plate (DWG. A1.1). Avoid knocks, jolts

and sudden movements when handling the machine.

Loading...

Loading...