Instruction manual for use and maintenance

for WM1L/S WM1L/S-M WM1L/E Single

head machines

File: 1927.doc - 25/01/02 11:55

26

5.5.2 Reed sensors

The Reed sensors (installed only on versions WM1L/S and WM1L/S-M) are installed on the

cylinder for the vertical blocking, of the welding plate and of the right movable plane.

These sensors do not need regulation in any case. In case of malfunction, the PLC will send a

message on the display.

5.5.3 Thermocouples

The thermocouple is sensor, which feels temperature.

The welding machine can be provided with one or two thermocouples: the first is installed on

the heating plate, the second is installed only if the machine is provided with the optional

“Heatable welding seal limitation blades”.

In this case the thermocouple is installed in the rear part of the of the lower left blade.

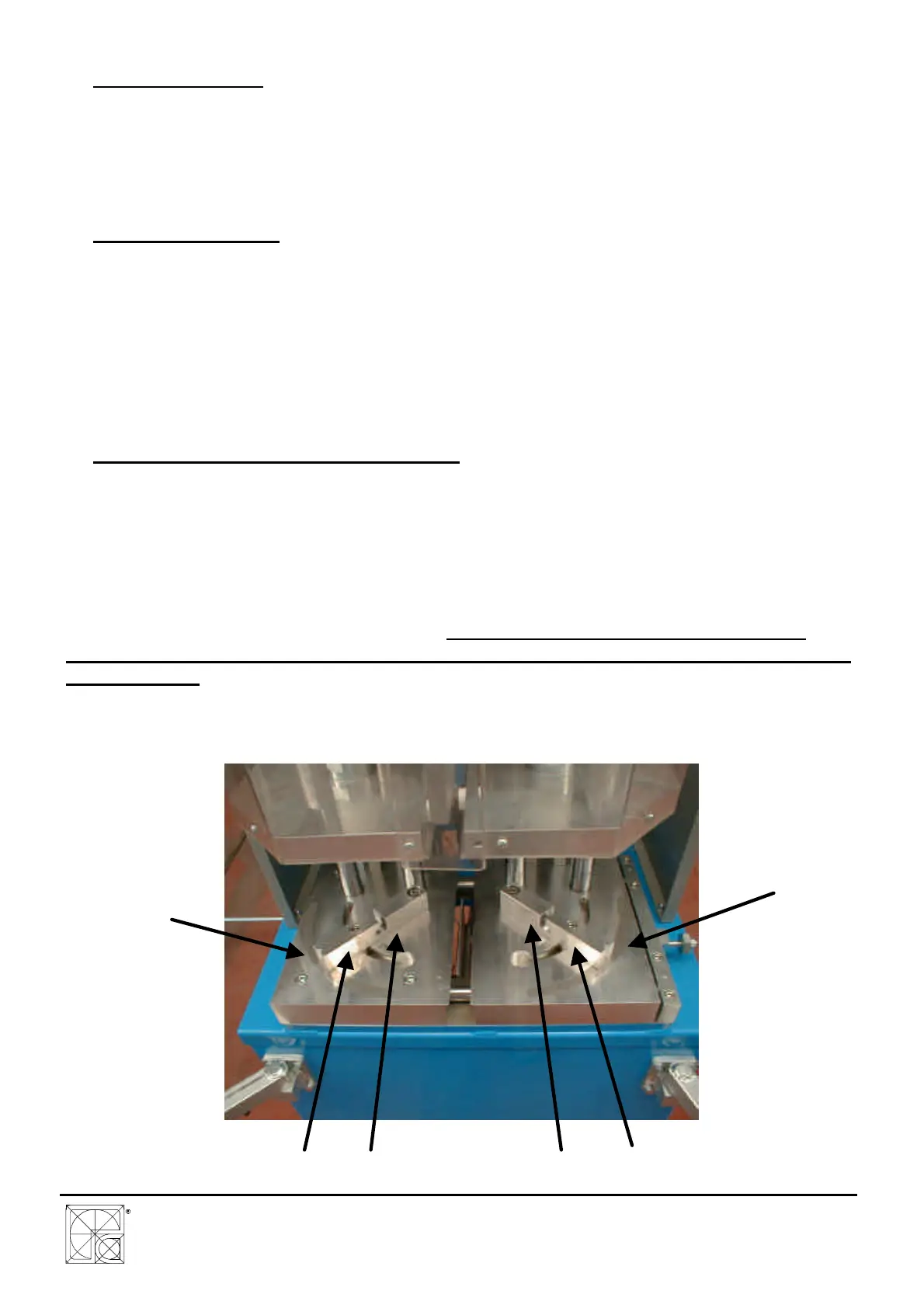

5.5.4 Welding at anlges different from 90°

The machine has the possibility to weld angles also with graduations different from 90°, it can

weld angles from a maximum of 180° to a minimum of 40°. To carry out this type of welding, the

operator will have to regulate the lateral profile holders. In order to do this proceed as follows:

- Partially loosen screws (1) and (2) (DWG. A1.20)

- Move holders (3) and (4) (DWG. A1.20) to the required graduation, matching the “V”-shaped

final parts of the holders with the value of the desired angle, which you will be able to read in

the relevant labels (5) and (6) (DWG. A1.20). Example: if the required angle is 60°, the

operator will have to move both holders (3) and (4) to the value 30°, that is the half of the

required angle.

- Tighten screws (1) and (2) (DWG. A1.20) completely and proceed with the normal processing,

as for angles at 90°.

DWG. A1.20

Loading...

Loading...