Instruction manual for use and maintenance

for WM1L/S WM1L/S-M WM1L/E Single

head machines

File: 1927.doc - 25/01/02 11:55

25

- When the time is run out (this timer concerns “cooling time”) the machine is completely

released, leaving the welded angle free.

5.4 Emergency device

At any time it is possible to stop the machine operations acting on the emergency push button

PE (DWG. A1.15). With this action, all cylinders return immediately into its home position.

To re-activate the machine, turn the push button in order to let it raise upwards.

5.5 Functionality of sensors

The machine uses three types of components to monitor the machine status.

1) Inductive sensor (which activates in the proximity of metallic objects)

2) reed sensors (which activates in the proximity of magnetic elements)

3) Thermocouple (supply a different tension value as the temperature varies)

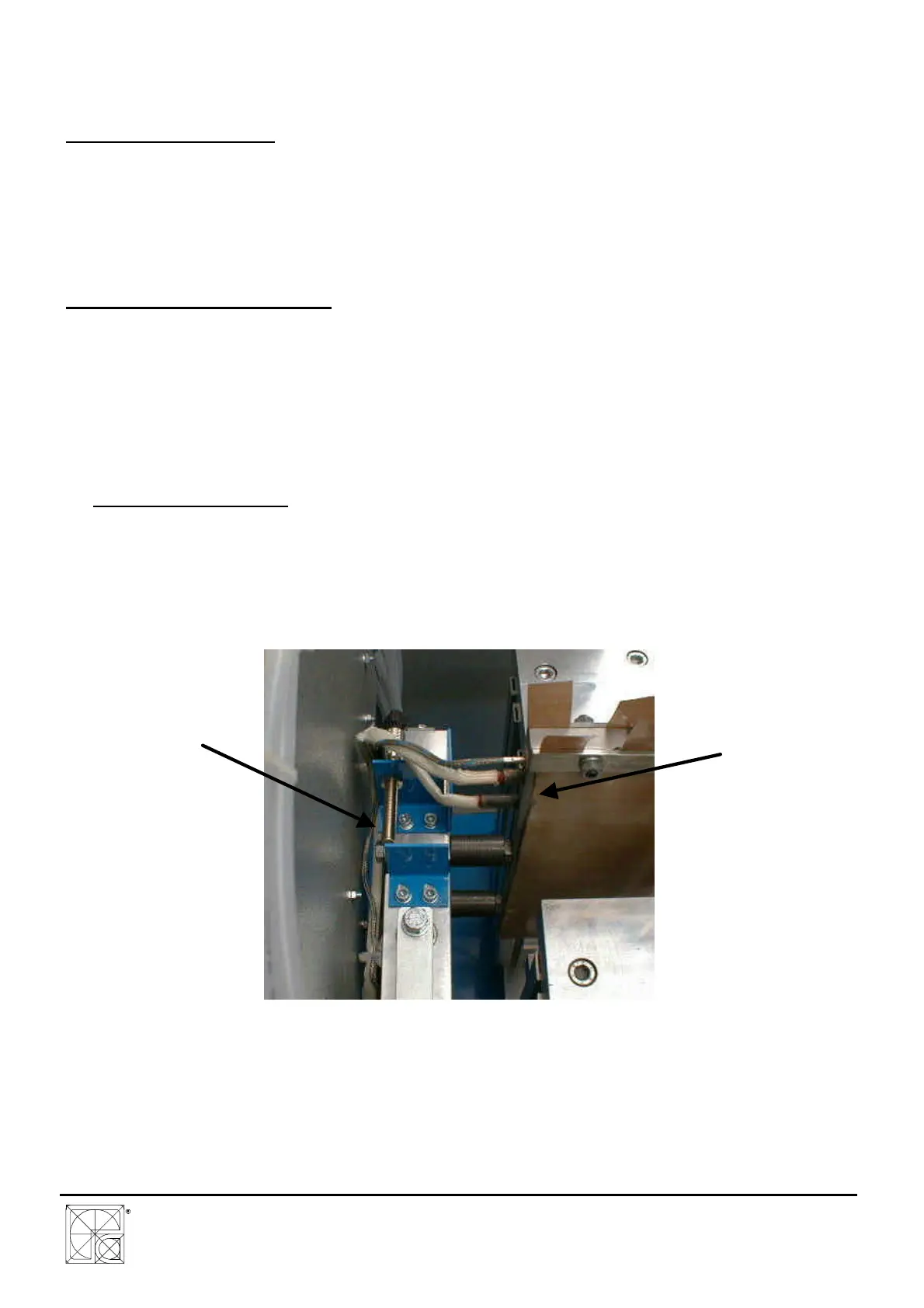

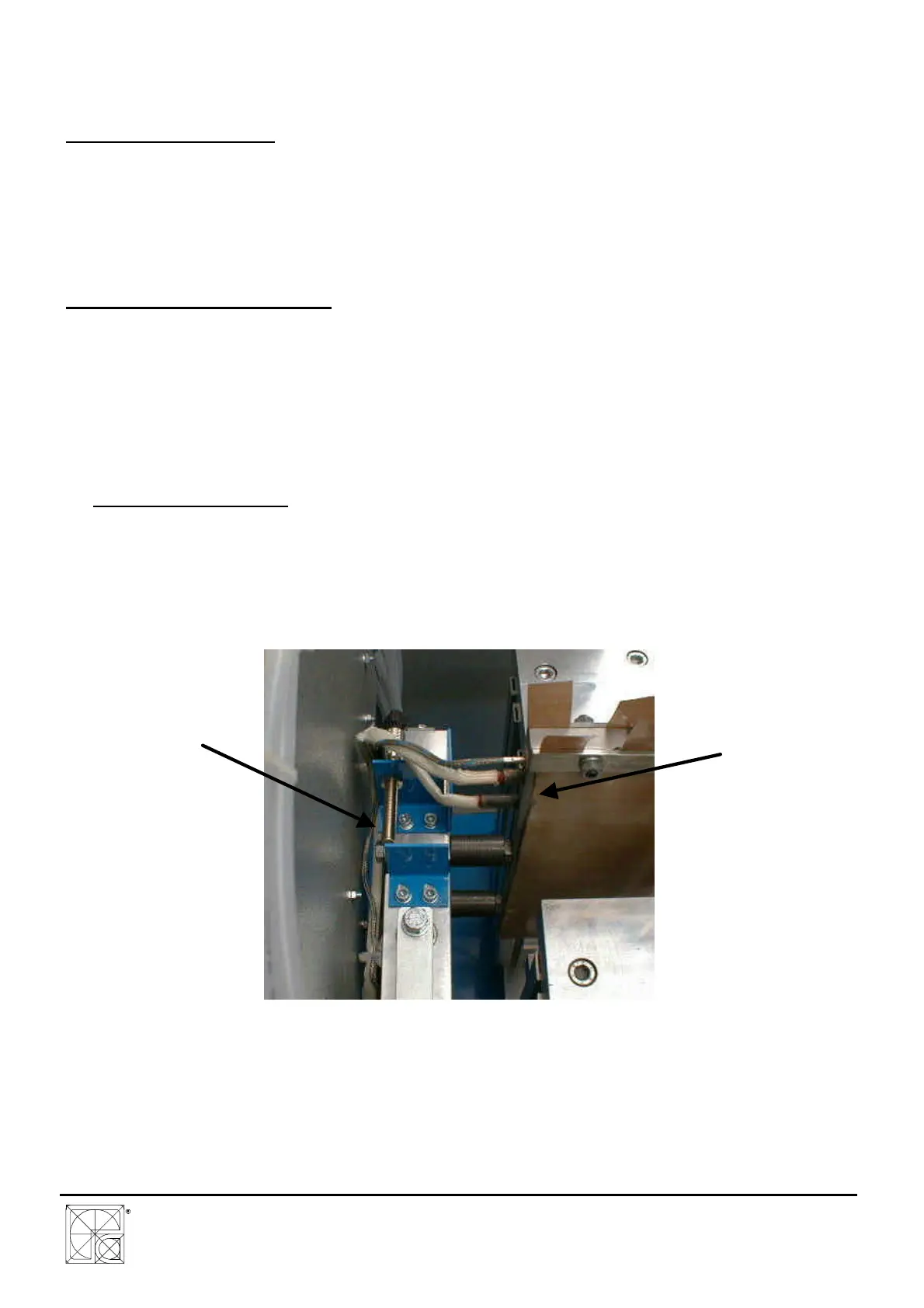

5.5.1 Inductive sensor

The inductive sensor controls the fusion state of the pieces (DWG. A1.19).

During the heating phase, all profiles as they get heat, reduce their length slightly, until they

reach a stop, which has previously been entered in the testing phase.

When the trolley reaches the mechanical stop, the inductive sensor activates and give the

enable signal to the PLC to go on with the working cycle.

DWG. A1.19

INDUCTIVE

SENSOR

THERMOCOUPL

Loading...

Loading...