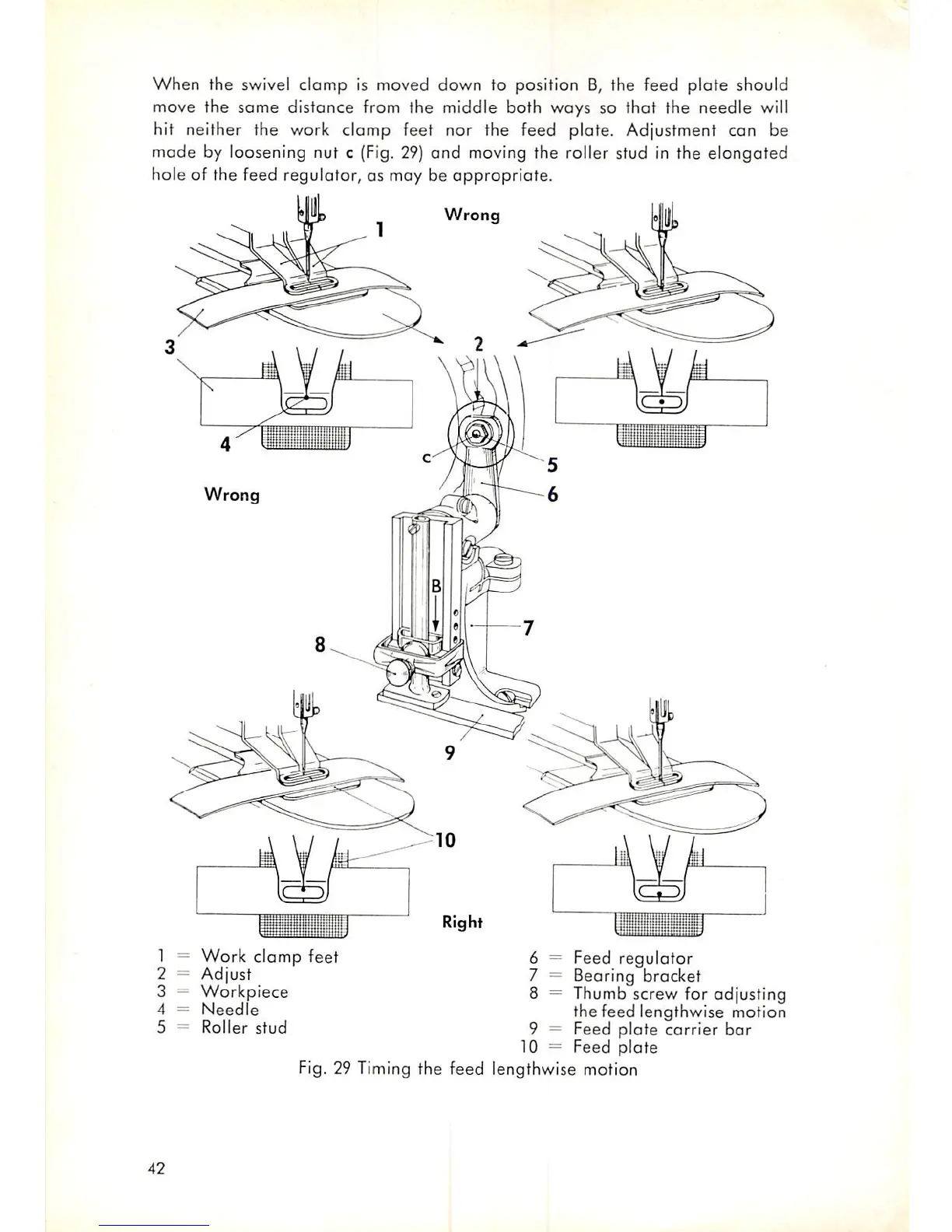

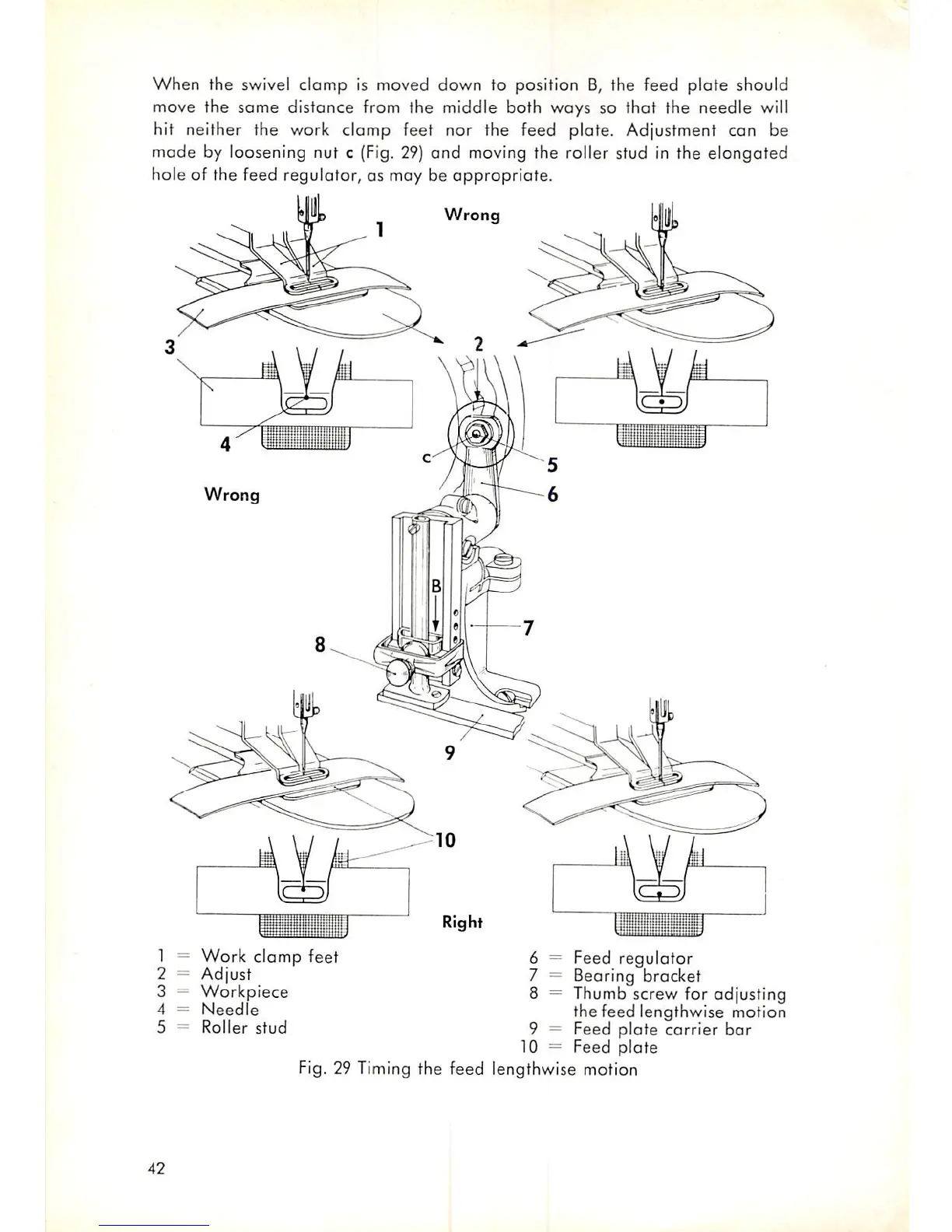

When the swivel clamp is moved down to position B, the feed plate should

move the some distance from the middle both ways so that the needle will

hit neither the work clamp feet nor the feed plate. Adjustment can be

made by loosening nut c (Fig. 29) and moving the roller stud in the elongated

hole of the feed regulator, as may be appropriate.

42

4'

« I

Wrong

Work

clamp feet

Adjust

Workpiece

Needle

Roller

stud

Wrong

Right

Fig. 29 Timing the feed

6 = Feed

regulator

7 = Bearing bracket

8 = Thumb screw for adjusting

the feed lengthwise motion

9 =

Feed

plote

carrier

bar

10 =

Feed

plate

lengthwise

motion

Loading...

Loading...