PHILIPS 3000 V2 01 INTRODUCTION

3/13

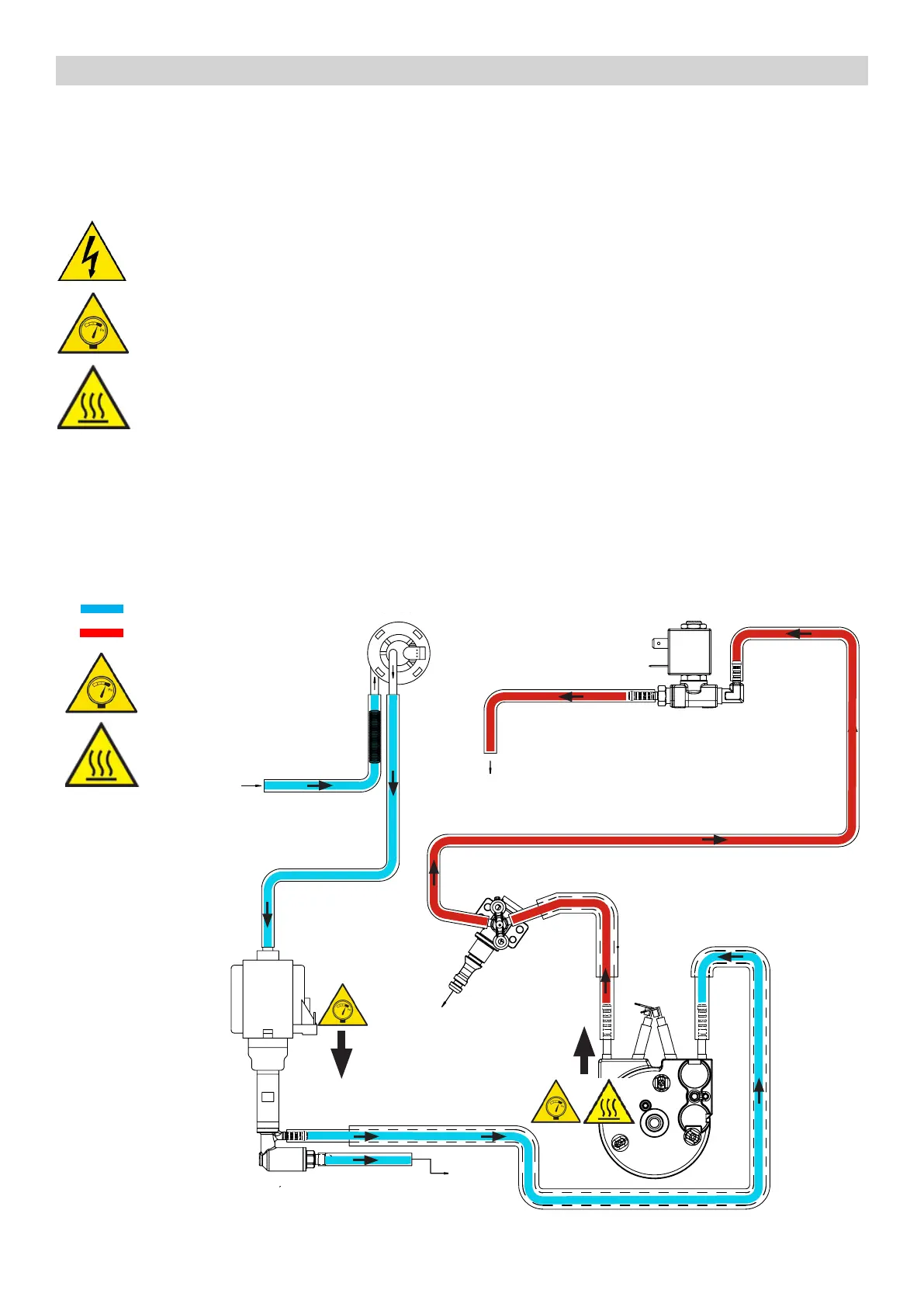

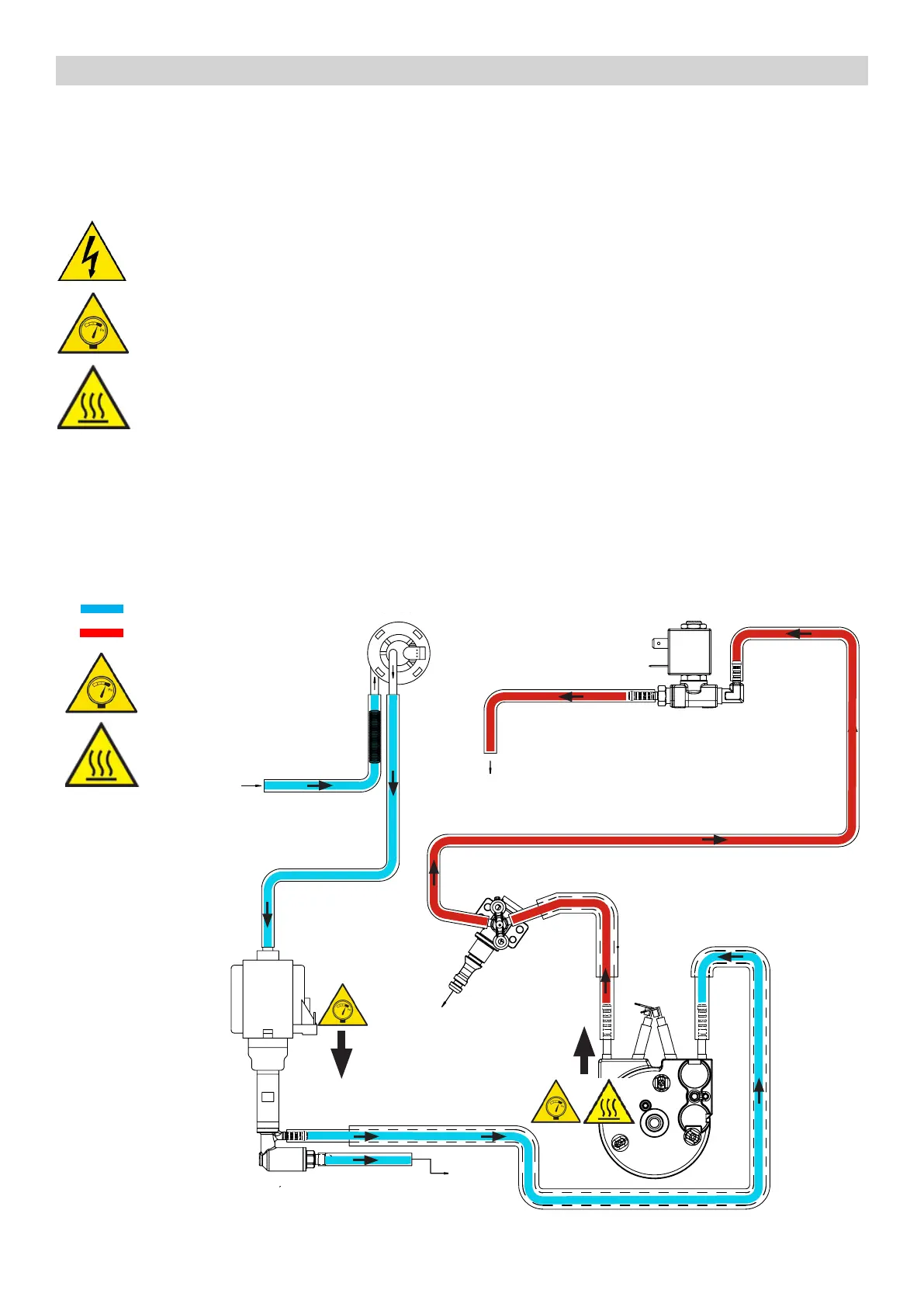

1.4. Safety warnings

Please, read the Service manual of the machine before starting any maintenance.

Operation, maintenance and/or repair of this device has to be carried out only by qualied persons, trained

for work at or with electric devices.

During the machine disassembly the operator has to pay attention to hot and under pressure parts.

All parts involved can be nd in the hydraulic circuit below schema.

e machine hydraulic circuit can reach maximum pressure of 16/18 bar.

When the machine arrives at the Service Center in descaling mode interrupted, or making Descaling , take

EXTREME CARE to avoid any unintentional contacts with the descaler.

Aer the product has been repaired, it should function properly and has to meet the safety requirements and

legal regulations as ocially laid down at this moment.

e technicians to operate under safety conditions, needs to:

1. Use personal safety devices;

2. Disconnect the appliance from the power mains before repairing;

3. Before and aer repair, it is recommended to perform dielectric strength tests (is domestic

appliance is rated as insulation class 1).

Pump

Safety valve

Water

discharge

Steam pipe

ter tank

Brewing Unit

Boiler

Water

Hot water /steam

From this point circuit

High temperaure

From this point circuit

in pressure

Flowmeter

Steam and hot water

Two-way solenoid valve

Pump

Brewing Unit

Boiler

Safety valve

Water

discharge

Water tank

Image 1

1.5. Water circuit diagram

Loading...

Loading...