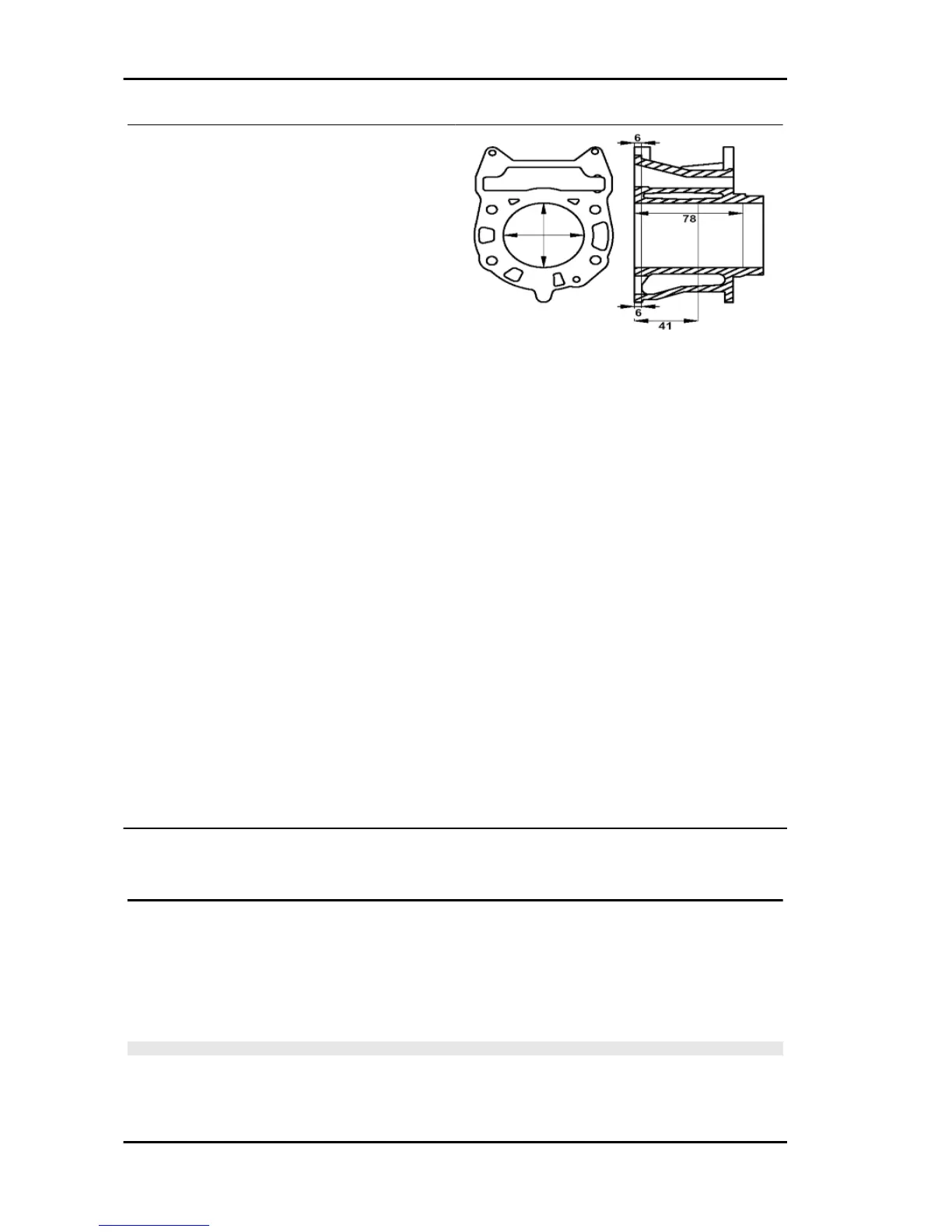

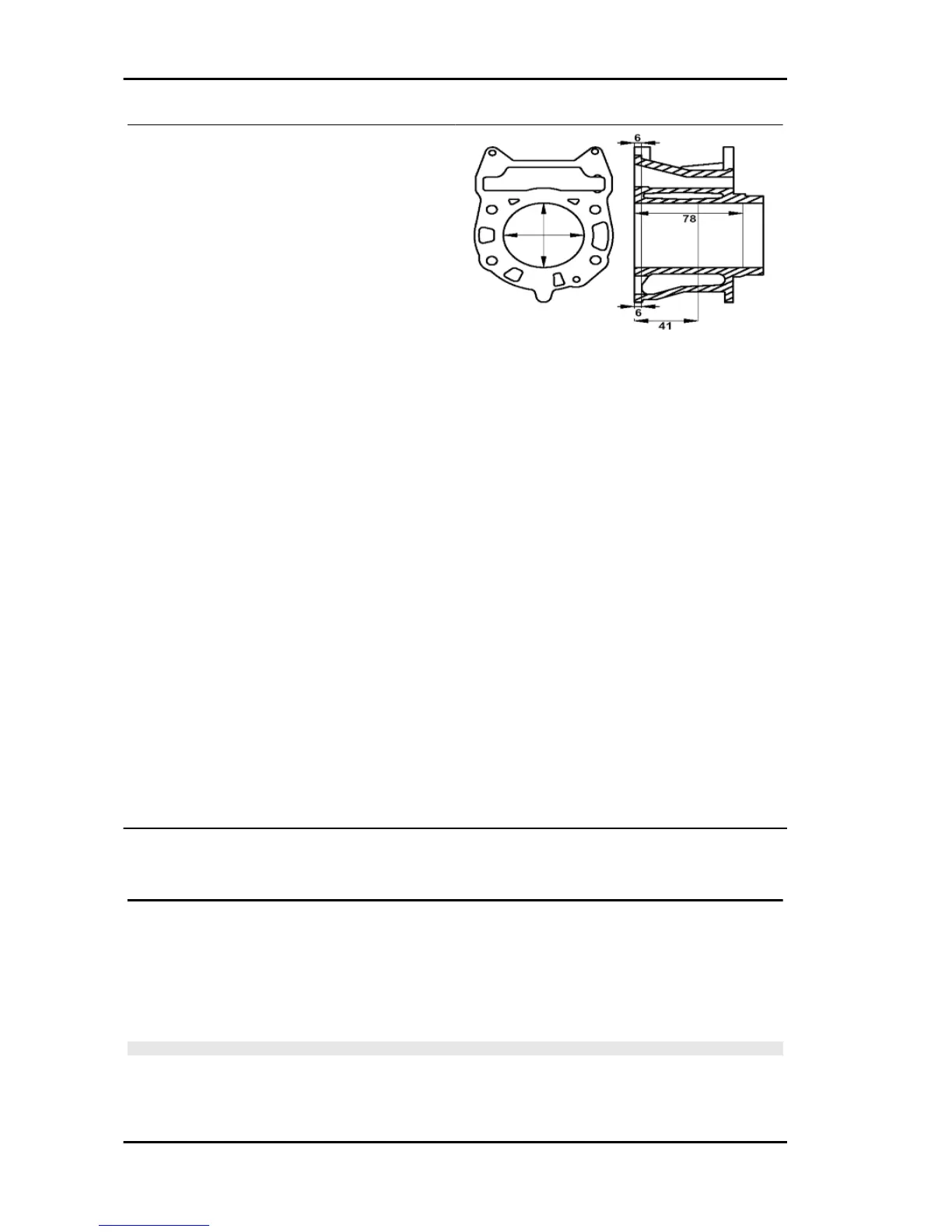

- Using a bore meter, measure the inner cylinder

diameter at three different points according to the

directions shown in the figure.

- Check that the head coupling surface is not worn

or misshapen.

- Pistons and cylinders are classified according to

diameter. The coupling is carried out in pairs (A-A,

B-B, C-C, D-D).

- The cylinder rectifying operation should be car-

ried out with a surfacing that respects the original

angle.

- The cylinder surface roughness should be 0.9

micron.

- This is indispensable for a good seating of the

sealing rings, which in turn minimises oil consump-

tion and guarantees optimum performance.

- The pistons are oversized due to cylinder grind-

ing and are subdivided into three categories- 1st,

2nd, 3rd corresponding to 0.2-0.4-0.6 mm oversi-

zes. They are also classified into 4 categories A-

A, B-B, C-C, D-D.

Characteristic

cylinder: standard diameter

56.997 - 57.025 mm (at 41 mm)

Maximum allowable run-out:

0.05 mm

Inspecting the piston rings

Version 125

Sealing rings

- Alternately insert the three sealing rings into the cylinder, in the area where it retains its original di-

ameter. Using the piston, insert the rings perpendicularly to the cylinder axis.

- Measure the opening (see figure) of the sealing rings using a feeler gauge.

- If any measurements are greater than specified, replace the piston rings.

N.B.

BEFORE REPLACING ONLY THE PISTON RINGS, ENSURE THAT THE CLEARANCE BETWEEN

THE PISTON RINGS AND THE PISTON RING GROOVES, AND BETWEEN THE PISTON AND THE

CYLINDER, IS AS SPECIFIED. IN ANY CASE, NEW PISTON RINGS USED IN COMBINATION WITH

A USED CYLINDER MAY HAVE DIFFERENT BEDDING CONDITIONS THAN THE STANDARD.

Engine B 125-250

ENG - 148

Loading...

Loading...