Action

Suspensions - check

Electrical system and battery - check

Headlight - adjustment

Tyre pressure and wear - check

Secondary air filter (250) - Cleaning

Vehicle and brake test - road test

(*) Vedere norme della sezione «Regolazione del minimo»

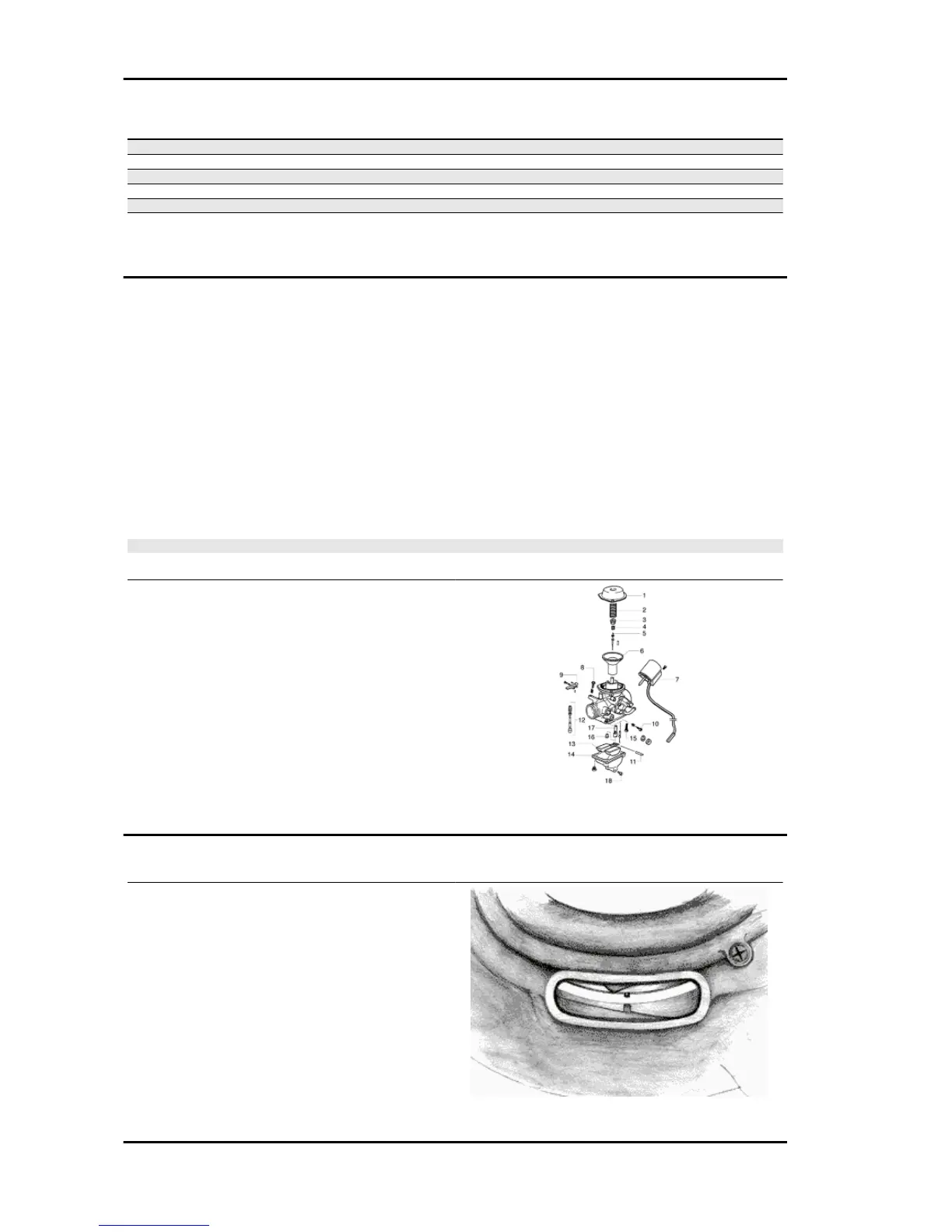

Carburettor

- Disassemble the carburettor in its parts, wash all of them with solvent, dry all body grooves with

compressed air to ensure adequate cleaning.

- Check carefully that the parts are in good condition.

- The throttle valve should move freely in the chamber. Replace it in case of excessive clearance due

to wear.

- If there are wear marks in the chamber causing inadequate tightness or a free valve slide (even if it

is new), replace the carburettor.

- It is advisable to replace the gaskets at every refit

WARNING

PETROL IS HIGHLY EXPLOSIVE ALWAYS REPLACE THE GASKETS TO AVOID PETROL LEAKS

1. Diaphragm cover - 2. Throttle valve spring - 3.

Conical needle support - 4. Conical needle spring

- 5. Conical needle - 6. Throttle valve diaphragm -

7. Automatic starting device - 8. Idle speed adjust-

ing screw - 9. Accelerating pump rocker - 10. Idle

mixture adjusting screw - 11. Float pin - 12. Accel-

erating pump assembly - 13. Float - 14. Float

chamber - 15. Idling jet - 16. Main jet - 17. Diffuser

- 18. Float chamber drain screw.

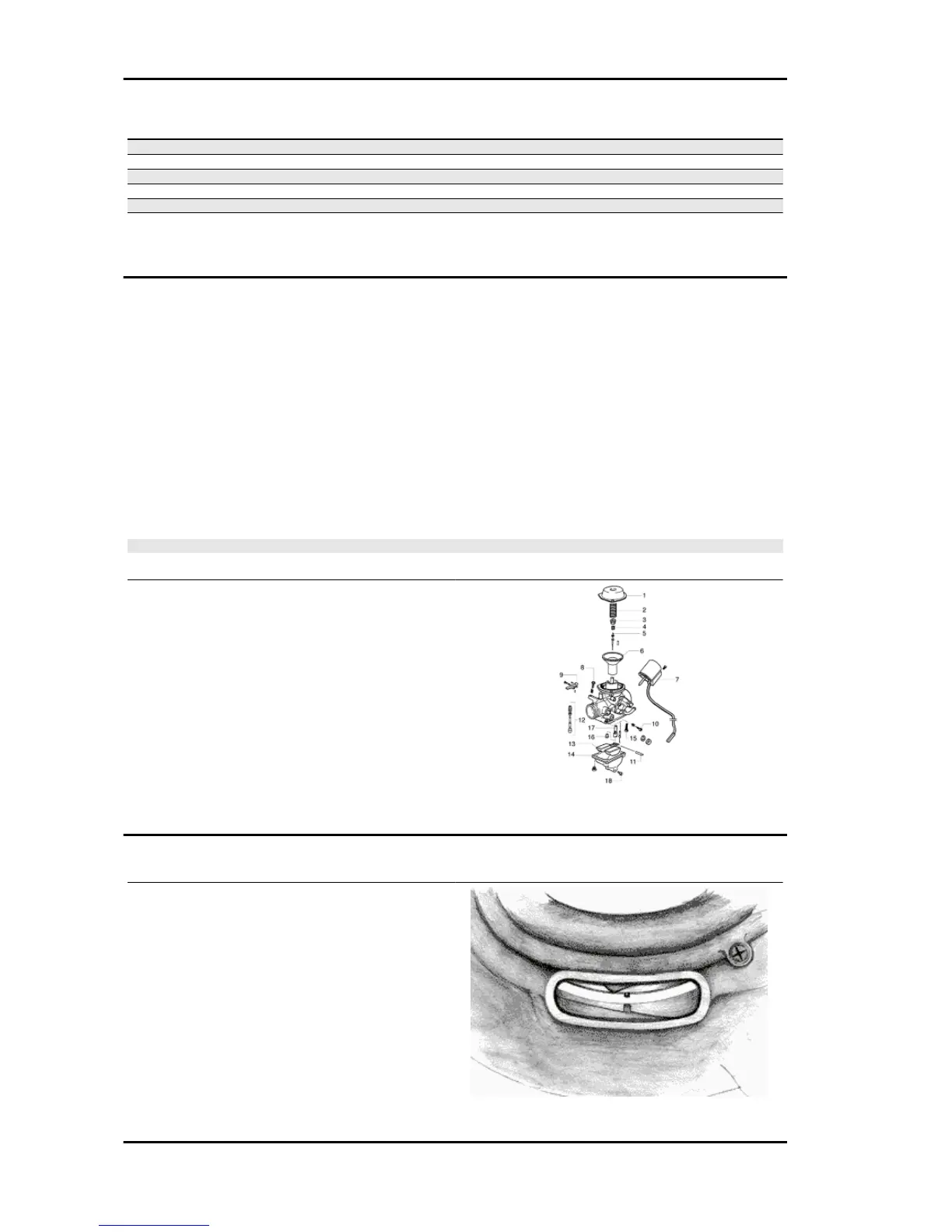

Checking the spark advance

- To check ignition advance, use the stroboscopic

light with induction pincers connected to the spark

plug power wire.

- Connect the induction pincers being careful to

respect the proper polarity (the arrow stamped on

the pincers must be pointing at the spark plug).

- Place the light selector in central position (1 spark

= 1 crankshaft turn as in 2-T engines).

Maintenance B 125-250

MAIN - 42

Loading...

Loading...