14-21. CHECKING COMPRESSOR OIL. The oil level should be checked any time the system is discharged.

The following steps should be followed to perform this check.

a. It will be necessary to discharge the system. (Refer to Paragraph 14-12.)

b. Fabricate an oil dipstick. (Refer to Figure 14-9.)

c. Remove the oil fill plug. (A .375 inch plug in the top side of the compressor crankcase.)

d. Before inserting the dipstick, the crankshaft Woodruff key should be located in the up position. (The

front face of the compressor clutch is marked with a stamped “K” indicating the key position.) The oil

level should be measured from the lowest point in the crankcase. Use the long end of the dipstick. (See

Figure 14-9.)

e. With the compressor in the installed position use Table XIV-III to determine the amount of oil in the

crankcase.

f. The compressor should never be operated with less than 6 ounces of oil. When oil is added the level

should not go above 10 ounces. Piper refrigerant oil PMS-L2000 or equivalent 500 viscosity

refrigerant oil must be used.

g. Evacuate and charge system. (Per Paragraphs 14-13 and 14-14.)

NOTE

The 10 ounce oil level is required in compressors installed on new systems.

Some oil is distributed in the system during operation. Replacement

compressors should be charged with 10 ounces of oil.

CAUTION

The oil plug should not be removed with pressure in the system.

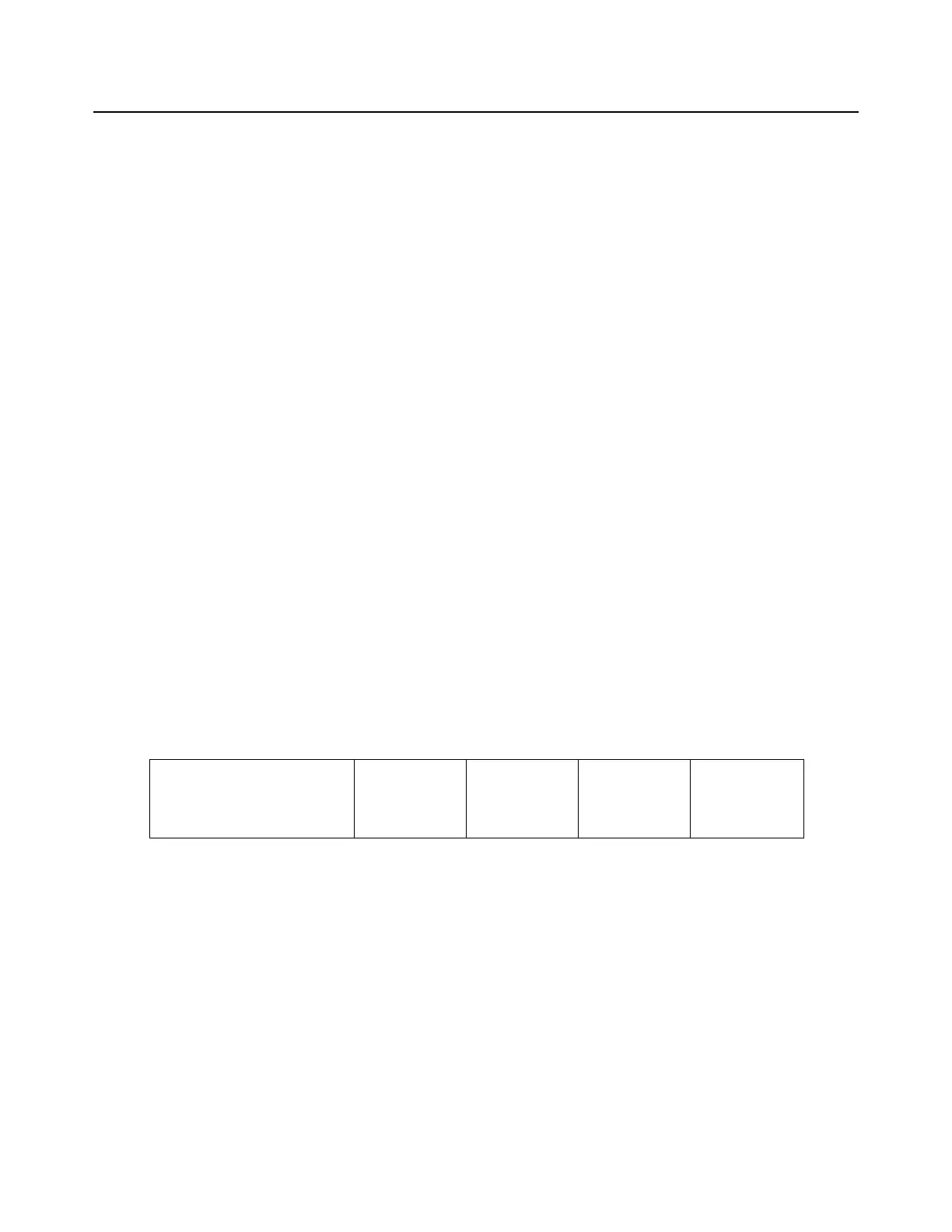

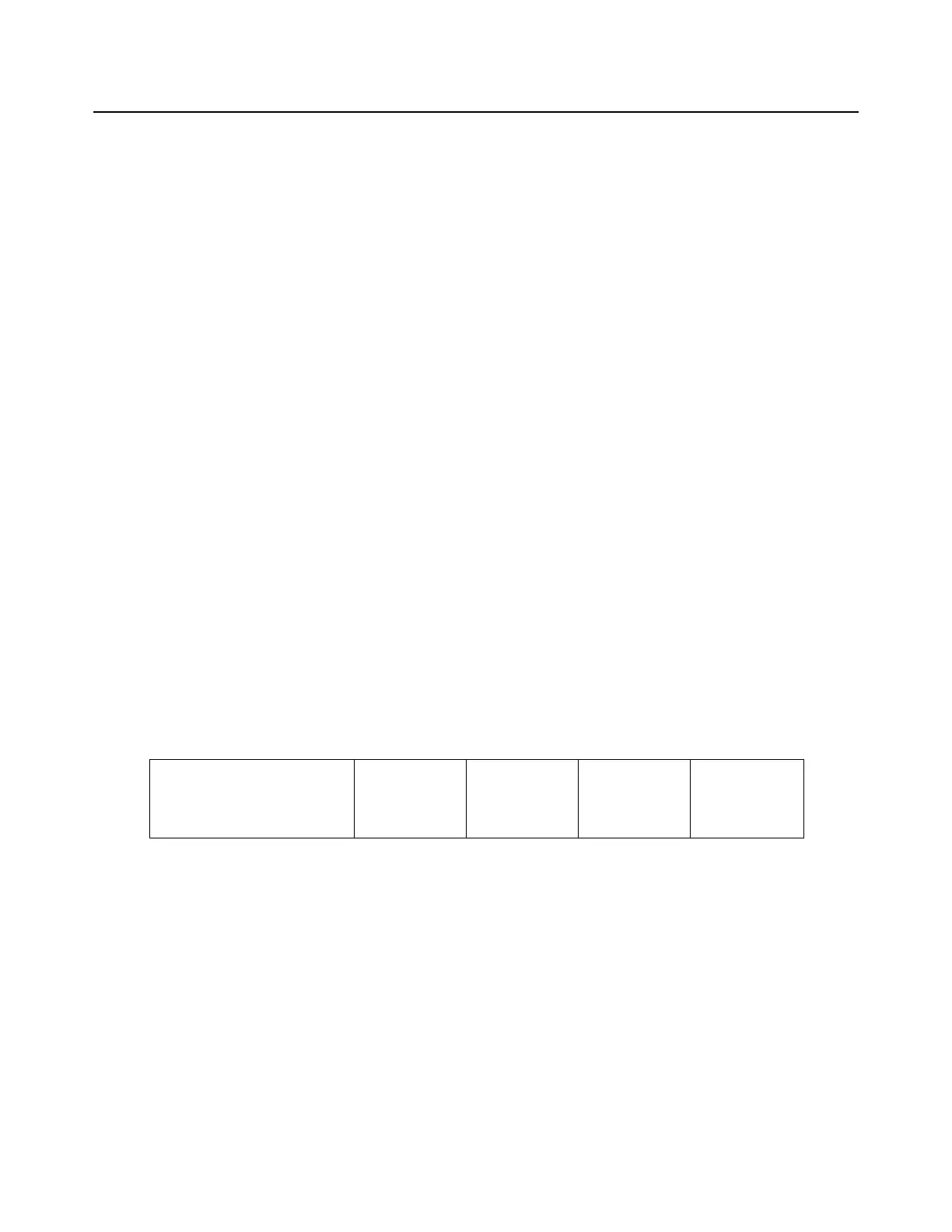

TABLE XIV-III. COMPRESSOR OIL CHARGE

Oil Charge Ounces 6 8 10 16

Dipstick Reading Inches 13/16” 1.00” 1-3/16” 1-15/16”

Issued: 1/3/78 ACCESSORIES AND UTILITIES

2K12

LANCE II SERVICE MANUAL

Loading...

Loading...