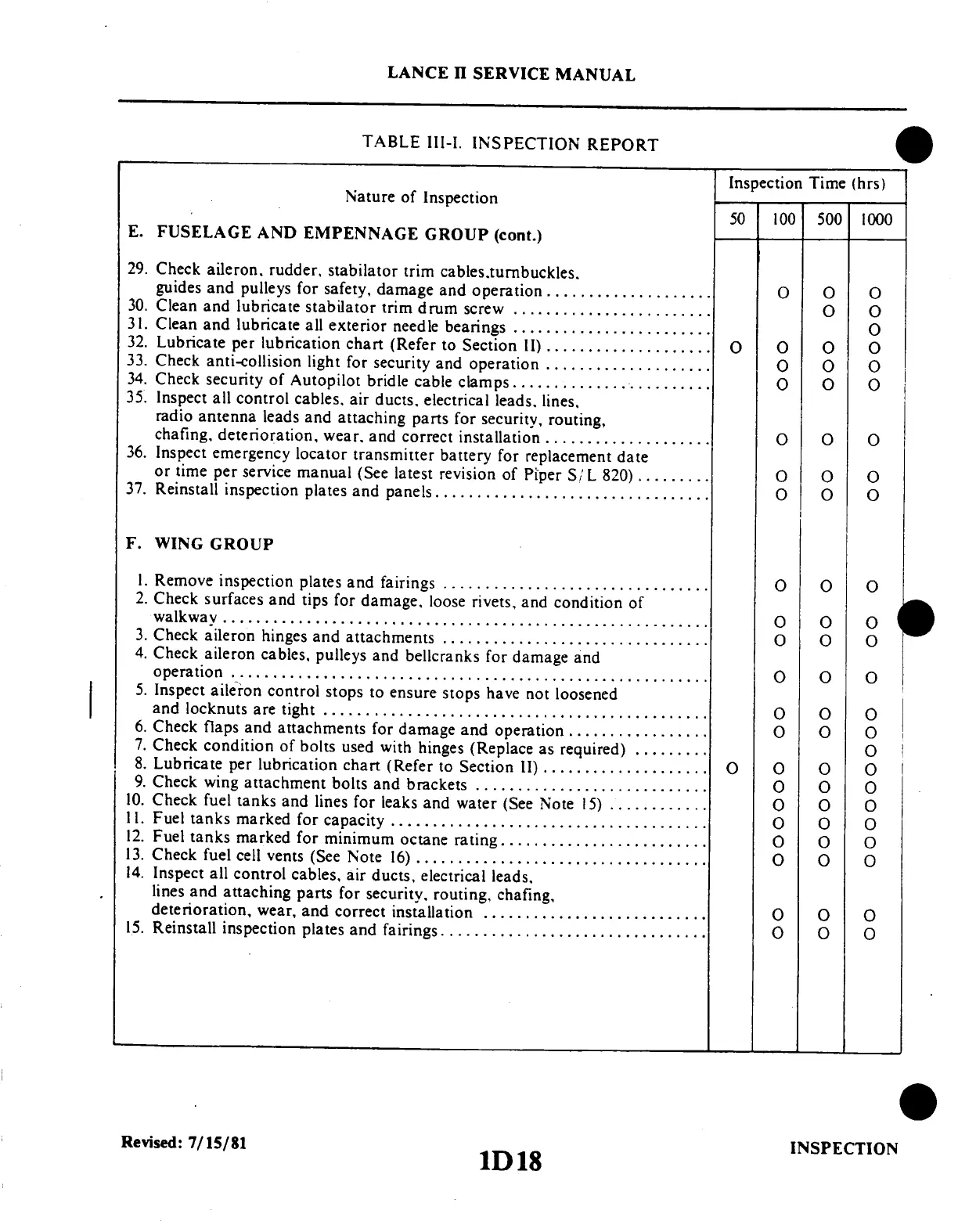

Nature

of

Inspection

E.

FUSELAGE

AND

EMPENNAGE

GROUP

(cont.)

29.

Check

aileron,

rudder,

stabilator

trim

cables.turnbuckles,

guides

and

pulleys

for

safety,

damage

and

operation

..

..................

30.

Clean

and

lubricate

stabilator

trim

drum

screw

........................

31.

Clean

and

lubricate

all

exterior

needle

bearings

........................

32.

Lubricate

per

lubrication

chart

(Refer

to

Section

II)

....................

33.

Check

anti-collision

light

for

security

and

operation

....................

34.

Check

security

of

Autopilot

bridle

cable

clamps........................

35.

Inspect

all

control

cables,

air

ducts,

electrical

leads,

lines,

radio

antenna

leads

and

attaching

parts

for

security,

routing,

chafing,

deterioration,

wear,

and

correct

installation

....................

36.

Inspect

emergency

locator

transmitter

battery

for

replacement

date

or

time

per

service

manual

(See

latest

revision

of

Piper

S/L

820)

.........

37.

Reinstall

inspection

plates

and

panels

................................

LANCE

II

SERVICE

MANUAL

TABLE

III-I.

INSPECTION

REPORT

Inspection

Time

(hrs)

50

100

500

1000

O

O

0

0

0

0

O

0

0

O

0

0

O

O

0

0

O

O

0

0

0

0

0

0

0

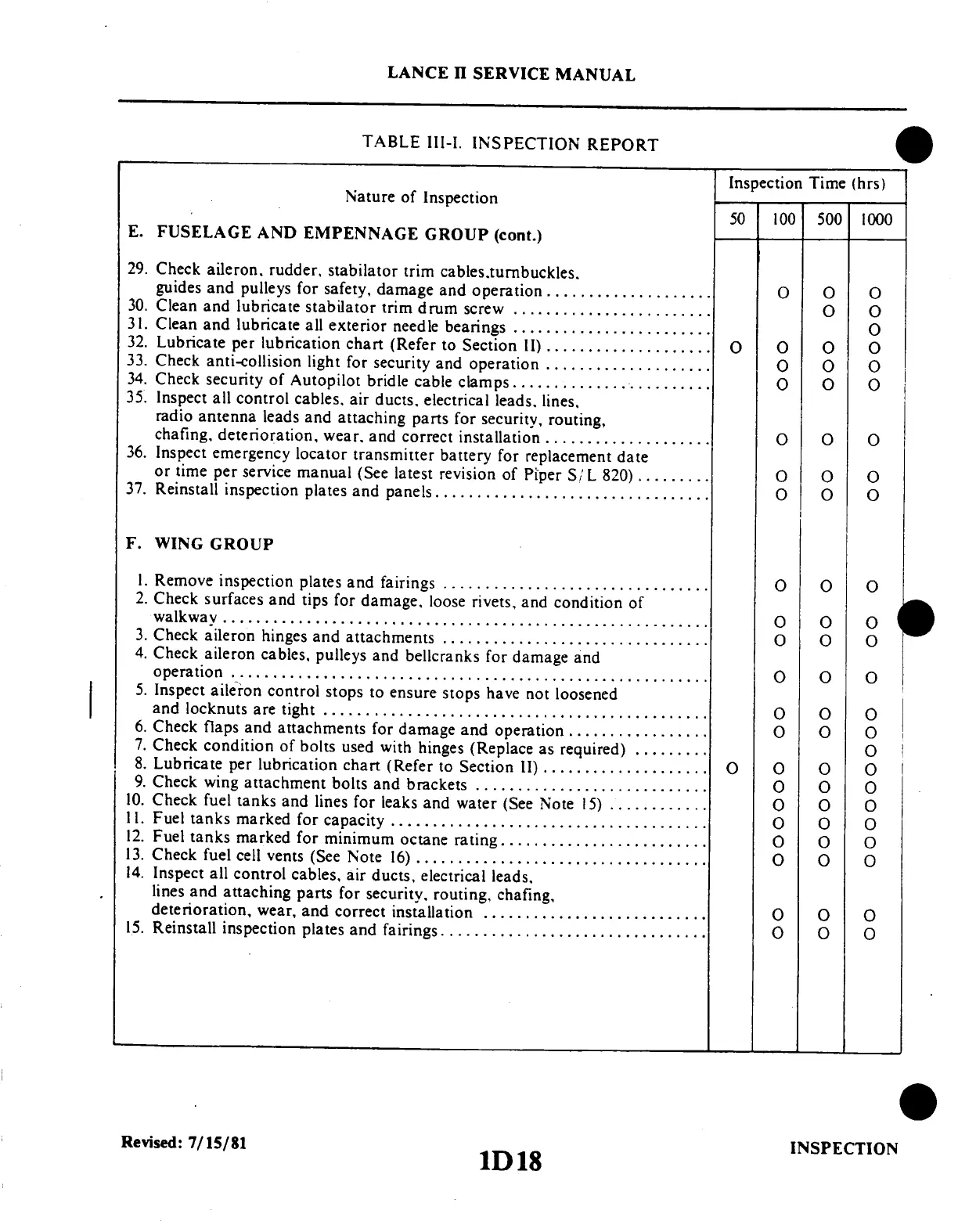

F.

WING

GROUP

1.

Remove

inspection

plates

and

fairings

................................

2.

Check

surfaces

and

tips

for

damage,

loose

rivets,

and

condition

of

walkwa

..........................................................

3.

Check

aileron

hinges

and

attachments

................................

4.

Check

aileron

cables,

pulleys

and

bellcranks

for

damage

and

operation

.........................................................

5.

Inspect

aileron

control

stops

to

ensure

stops

have

not

loosened

and

locknuts

are

tight

..............................................

6.

Check

flaps

and

attachments

for

damage

and

operation

...............

7.

Check

condition

of

bolts

used

with

hinges

(Replace

as

required)

.........

8.

Lubricate

per

lubrication

chart

(Refer

to

Section

II)

....................

9.

Check

wing

attachment

bolts

and

brackets

............................

10.

Check

fuel

tanks

and

lines

for

leaks

and

water

(See

Note

15)

............

1.

Fuel

tanks

marked

for

capacity

......................................

12.

Fuel

tanks

marked

for

minimum

octane

rating

.........................

13.

Check

fuel

cell

vents

(See

Note

16)

....

...............................

14.

Inspect

all

control

cables,

air

ducts,

electrical

leads,

lines

and

attaching

parts

for

security,

routing,

chafing,

deterioration,

wear,

and

correct

installation

...........................

15.

Reinstall

inspection

plates

and

fairings

...

....

........................

O

0

0

0

0 0

O

0

0

0

0

0

0

0

0

0

0

0

O

0

0

O

0

0

0

0

0

0

0

0

O O O

0

0

0

0

0

0

0

0

Revised:

7/15/81

INSPECTION

1D18

Loading...

Loading...