Chapter 5 Function parameter

68

20=20*(20%+F2.17),work out F2.17=0.8

Example 2:

Change the output 0~10V to 0~5V

According to the formula, minimum input voltage value: y1=10*F2.16*100%,

0=10*F2.16, work out F2.16=0.0%;

According to the formula, maximum input voltage value:y2=10*(F2.16+F2.17);

5=10*(0+F2.17),work out F2.17=0.5

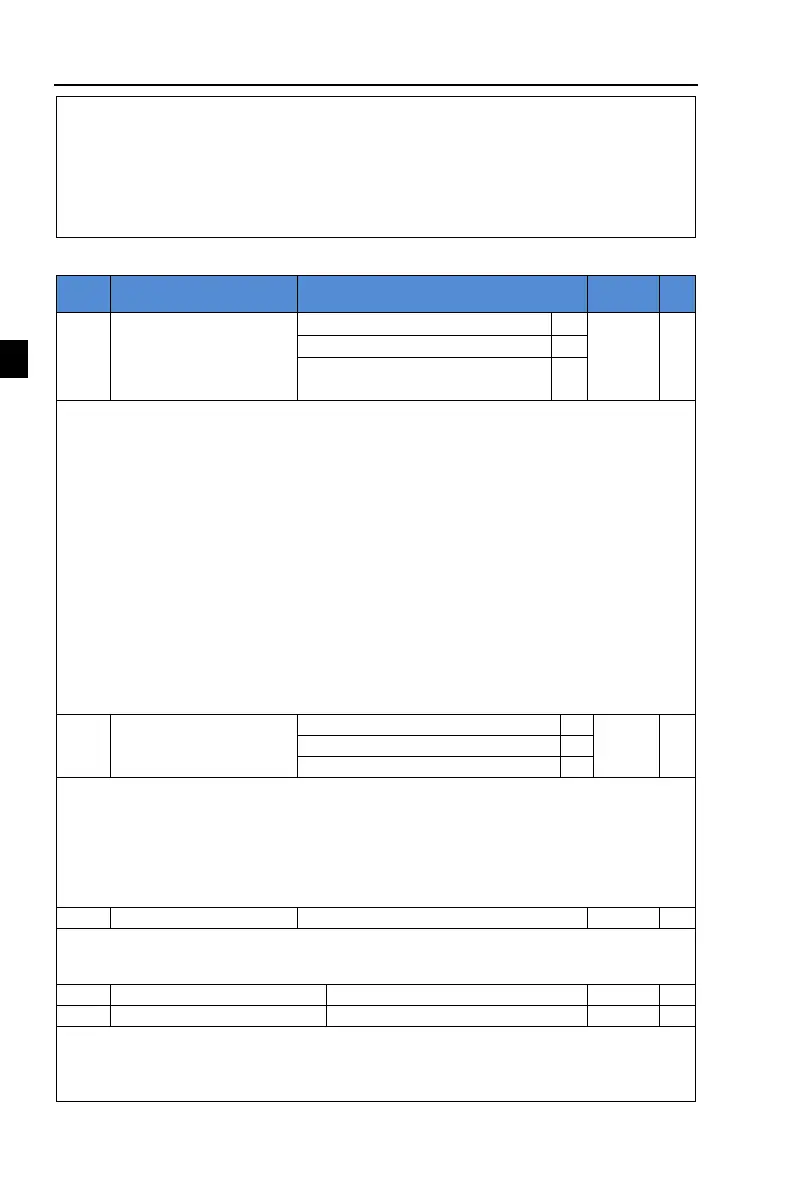

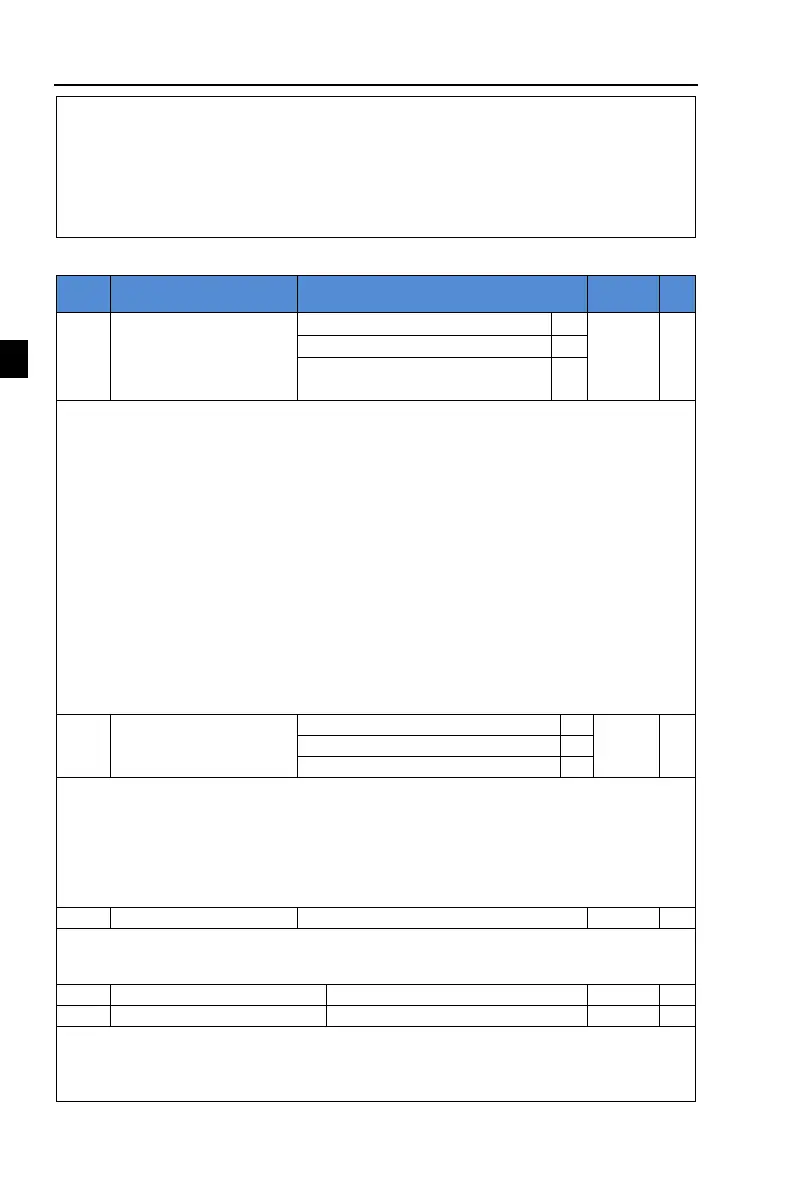

5-2-5.F3 group Start and stop control group

Pre-excitation start (AC

asynchronous motor)

0: Directly startup

If the start DC braking time is set to 0, the inverter starts running from the start frequency.

If the start DC braking time is not set to 0, the inverter firstly performs DC braking and then

starts running from the start frequency. Applicable for the small inertia load and the application

that the motor may rotate when starting.

1: Speed tracking restart

The inverter firstly judges the speed and direction of motor, and then starts at the tracked

motor frequency, smoothly starts the rotating motor without shocks. Applicable for the

momentary power cut and restart with high inertia loads. To ensure the performance of Speed

Tracking Restart, it is required to accurately set the parameters of motor b0 group.

2:Asynchronous motor pre-excitation start

Used to firstly create magnetic field before the motor running. Please refer to the

instructions of function code F3.05, F3.06 for pre-excitation current and pre-excitation time.

If the pre-excitation time is set to 0, the inverter will cancel the pre-excitation process, and

starts from the start frequency. If the pre-excitation time is not set to 0, the inverter will firstly

perform pre-excitation process and then starts so as to improve the dynamic response

performance of motor.

Start from stop frequency

Start from maximum frequency

For the shortest time to complete the process of speed tracking, select the speed mode for

inverter tracking motor :

0: Track downward from the frequency that power outage happens,Usually select this

mode.

1: Track upward from 0 frequency,for the case that power outage is for longer time and

then restarts.

2: Track downward from maximum frequency,for the general power generation load.

When performing speed tracking restart, select speed tracking value.

Soft track:The larger the parameter value, the faster tracking. But if the value is set to too

large, which may cause tracking unreliable.

Hold time for start frequency

When the inverter starts, firstly run at the start frequency, the running time is the hold time

for start frequency, afterwards run at the frequency reference.

The start frequency F3.03 is not limited by the lower limit frequency. But if the set target

frequency is less than the start frequency, the inverter does not start and keeps in the standby

Loading...

Loading...