4544

Low-To-High Fire Delay (Menu 5)

This setting is used to set the minimum amount of time that must elapse between the

low fire valve opening and the high fire valve opening. This setting is only available if Low

Fire is enabled in menu 5. The Low-to-High Fire Delay is used to ensure that enough draft

is established before switching to high fire. If this is not done, the volume of gas flowing

through the high fire valve can snuff out the flame due to insufficient oxygen supply.

Generally, the larger the burner, the larger the delay should be. This setting can be set to a

minimum of 30s and a maximum of 300s. Values set above 255s are automatically set to the

value minus 255s.

Pressure/Level Delay (Menu 4)

This setting is used to reject spurious electrical noise that may be present on the Low

Pressure Contact, Level Contact, and the 4-20mA Expansion Card (if installed). This noise

can come from electrical interference, mechanical vibration, or small oscillations in gas

pressure and tank level. The rejection is accomplished by requiring these contacts to remain

open for a continuous period of time (called the “delay”) before shutting down. In the case

of the 4-20mA Expansion Card, the Pressure and Level readings must remain below their

respective low setpoints for the delay time before shutting down. If the Level Event Restart

is enabled in the restart settings, the delays are applied before entering a waiting state as

opposed to shutting down.

This setting can be set to either enabled or disabled. When disabled, there is a small delay.

When enabled, the delay is lengthened. There are separate delays for Pressure and Level, as

well as for contacts and 4-20mA input readings. The following tables list the delays used in all

cases.

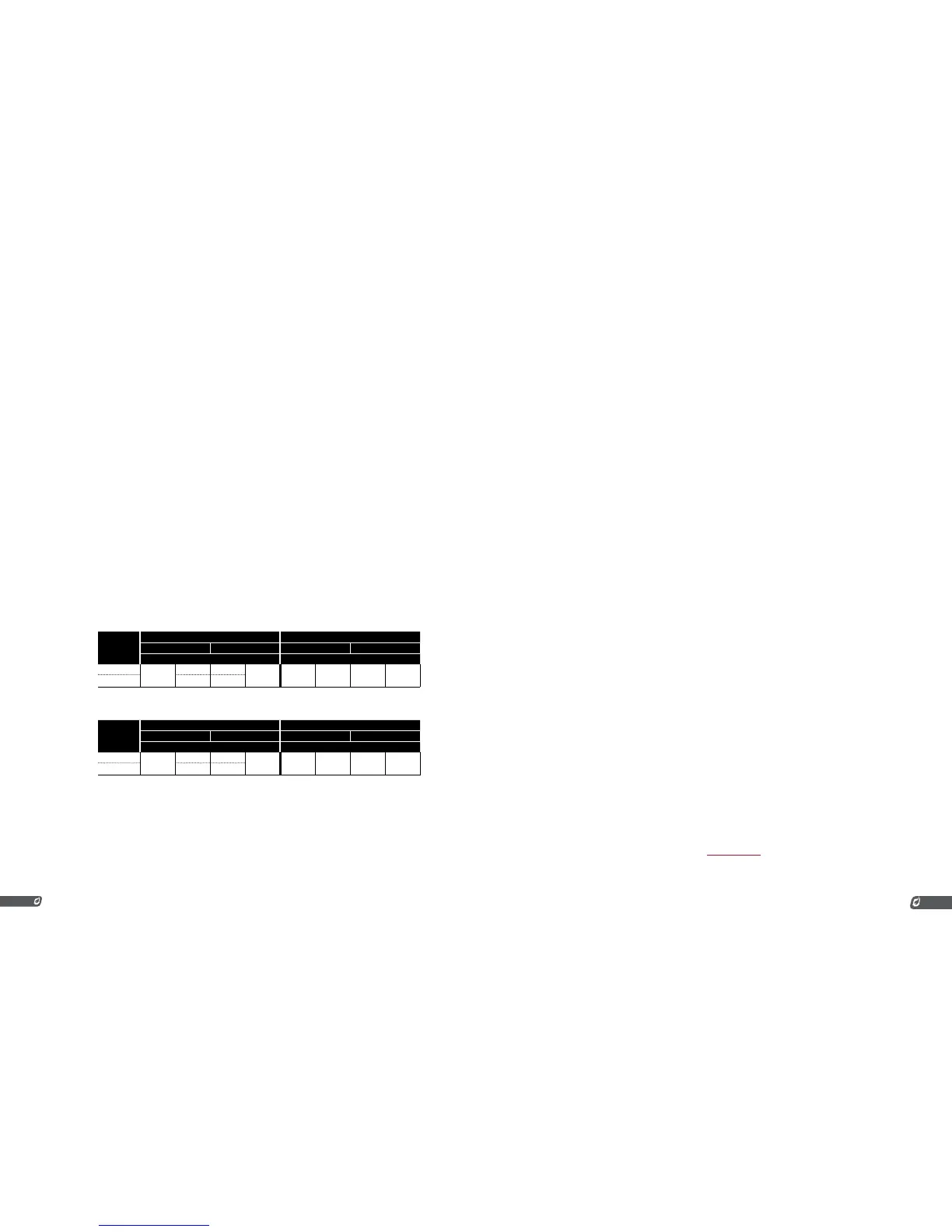

Pressure Delay Table

SETTING

LOW PRESSURE HIGH PRESSURE

4-20mA Contact 4-20mA Contact

Rising Falling Opening Closing Rising Falling Opening Closing

Enabled

2s

6s 6s

0s 2s 2s 0s 0s

Disabled 2s 2s

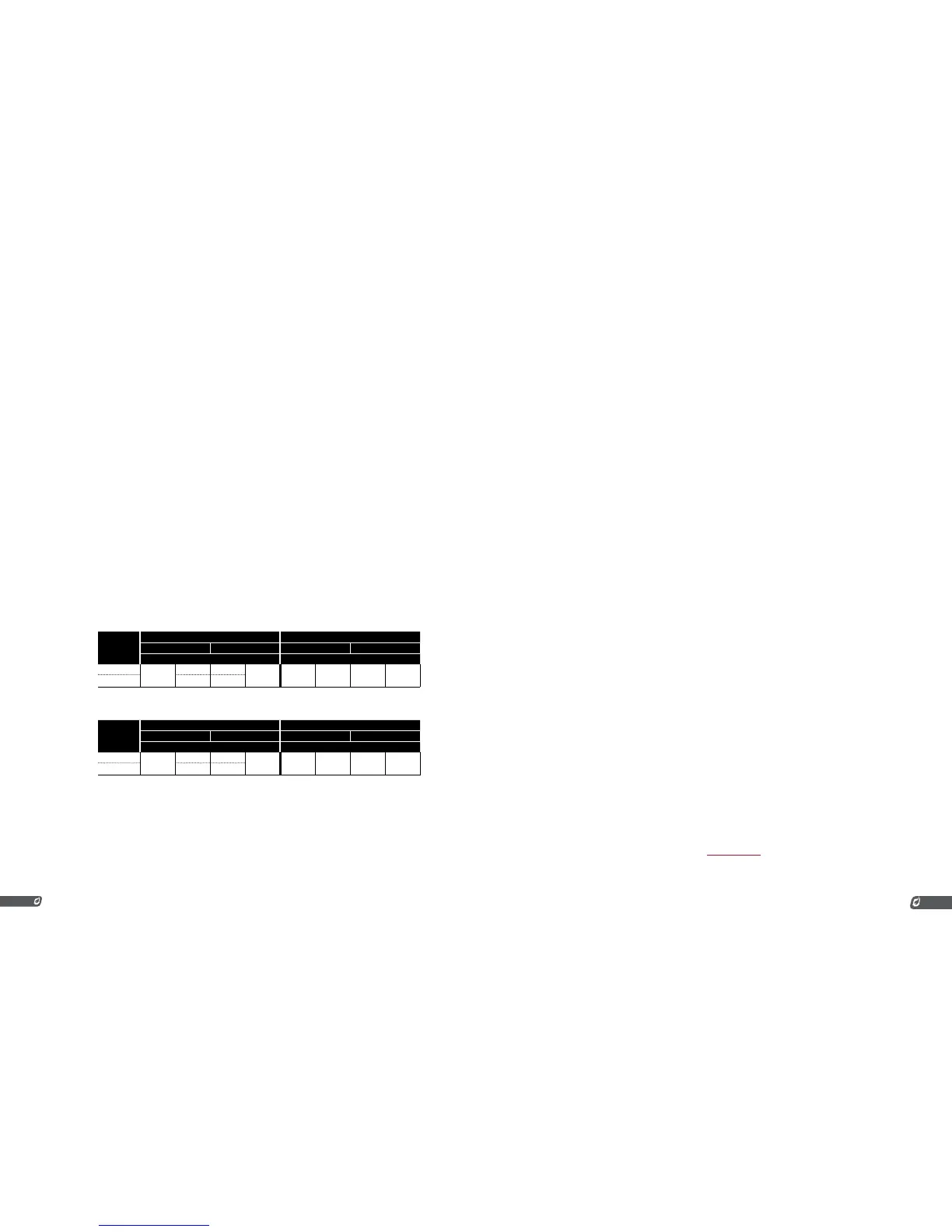

Level Delay Table

SETTING

LOW LEVEL HIGH LEVEL

4-20mA Contact 4-20mA Contact

Rising Falling Opening Closing Rising Falling Opening Closing

Enabled

2s

20s 20s

0s 0s 0s N/A N/A

Disabled 2s 2s

3.6 | System Operation

This section includes information about how to start and stop the system, how to review key system

settings, how to adjust setpoints while the system is running, and how to check the system firmware

versions.

STARTING THE SYSTEM

There are five different ways to start the system:

Auto Mode Option

The system is set to Manual Mode by default. Setting the system to Auto Mode is the most

common way to start the system.

1. Make sure the system is stopped, all alarms are clear, and the

Home Screen displays “Ready”.

2. Press the Mode Key. A confirmation prompt will show on the

Display.

3. Press the OK Key to confirm that you want to start the

system.

This changes the system to Auto Mode. Based on the defined system settings, the system

will automatically restart from faults. The system will take over turning the valves on and off

according to the system settings and the current Process Temperature.

System Test And Start Option

This method is used during the initial installation when testing the pilot valve, main valve,

ignition circuit, and flame detection circuitry in a slow sequence.

1. Make sure the system is set to Manual Mode and is stopped

with all alarms clear. The Home Screen should display “Ready”.

2. Press and hold the Pilot Key to open the Pilot Valve. Listen for

the Pilot Valve to click open and let the gas through. Continue

to hold the Pilot Key and press and hold the Ignite Key to

begin sparking. Check the Pilot Nozzle for sparks and flame.

If you cannot see the Pilot Nozzle, listen for the sound of

sparking and try to determine if it is coming from the ignition

rod.

3. Release the Ignite Key and check that the display shows a

Flame Quality of 100%.

4. After about 5 seconds, the display will show “Pilot On” if the

Pilot lit successfully.

5. Press the Main Key to open the Main Valve. The system will

count down the Pilot-to-Main Delay and then open the Main

Valve if the Process Temperature is within the expected range.

6. The system will take over turning the valves on and off

according to the system settings and the current Process

Temperature.

7. Press the Mode Key to switch the system into Auto Mode.

This allows the system to automatically restart from faults

specified in the system settings.

If any of these checks fail, consult the troubleshooting section of this guide.

Loading...

Loading...