1514

the product. Moisture damage to the internal circuitry is not

covered by the product warranty if the door has been left

open.

6. All conduit ports drilled into the PF2100 enclosure must be

CSA/NEMA Type 4 rated and be sealed in order to maintain the

Type 4 rating.

2.2 | Mounting Considerations

The PF2100 is typically mounted near the burner it is controlling or in another location that is both safe

and easily accessible. The recommended mounting height is 1.5m (5ft) above the ground or platform for

the comfort of the operators.

PLEASE CONSIDER THE FOLLOWING WHEN CHOOSING AN INSTALL LOCATION:

Accessability

The system should be easily accessible so that the operator can change settings and observe

its operation. It is preferable that the system be mounted facing away from the sun to make

it easier to read the display and LED indicators on the front panel.

Security

In some situations, it may be desirable to mount the system in a location not accessible to

the general public to prevent accidental or intentional tampering.

Operator Safety

Avoid placing the system in locations that are dangerous to the operator. Examine the area

surrounding the potential installation site and look for such things as nearby open flames or

close proximity to tanks that might overflow, and other harmful situations.

Performance

Choose a mounting location that allows ground and ignition wires to be kept as short as

possible. This ensures the best ignition and flame detection.

Product Protection

To protect the system from being damaged, it should not be mounted:

1. Where chemicals may splatter or bubble over from a tank onto

the system. Chemicals on the keypad may interfere with an

operator’s ability to control the product or view the display and

LED indicators.

2. Directly to a heated tank where excessive heat may damage

the product. Refer to the maximum operating temperature

listed in this document.

3. On anything that may tip over due to wind or snow. Some

examples include poles not set properly into the ground or

tripods not secured with anchor bolts or guy wires.

4. In locations that may be prone to flooding.

CONDUIT AND CABLE CONSIDERATIONS

FLAME

MC#2

48705

1 8 5 5 P R O F IR E

WAR

NING: EXP

LOSI

ON

HAZARD

D

O

NOT DISCONN

EC

T WHILE CIRCUIT IS

LI

V

E UN

LES

S AREA IS KNO

W

N

TO B

E NON-HAZARDOUS OR EQUIVALENT

AVER

TISSE

M

ENT: RISQUE D’

EXPLOSION

NE PAS DEBRANCHER TANT

QUE LE CIRCUIT EST S

OUS

TENSIO

N, A

MOUNS QU’IL N

E S’AG

ISSE D’UN EMPLAC

EMENT

NON DANGEREAUX

WAR

NING: EXP

LOSI

ON

HAZARD

S

U

B

STITU

T

IO

N OF

COMPON

ENTS MAY

IMPAIR SUITABILITY FOR

C

LASS I, D

IVISION 2.

AVER

TISSEMENT: RISQUE D’

EXPLOSION

LA SUBSTITUTION DE COMPOSANTS PEUT RENDURE CE MATERIEL

INACCEPTABLE POUR LES EMPLACEMENTS D

E CLASS

E I, DIVISION 2

CSA 22.2 No. 1

99-2007

ANSI Z21.20-

2007

UL1998-2004

Class 1, Div 2, G

rp ABCD

IP54

T4A, NEMA Type 4X

INP

UT: 12VD

C, 2.6W Display O

N

12VD

C, 1.1W Display O

FF

2

4VD

C, 2.9W Display O

N

2

4VD

C, 1.2W Display

O

FF

OUTPUT: 1

2VDC, 5A

max IN

D

UCTIVE

24VD

C, 5A max INDUCTIV

E

AMBIEN

T: -40˚C - +55˚C

THIS EQUIPMENT

IS SUITABLE FOR USE IN CLASS

I, DIVISION 2,

GROUPS ABCD OR NON-HAZARDOUS LOCATIONS ONLY.

1101-009-E0000 Rev 3.

0

SERIAL

NO.

MODEL N

O.

1PS21-E0000

D E MO

BURNER

MANAGEMENT SYSTEM

2100

DETERMINE DRILL LOCATIONS

CONDUIT AND CABLES AS REQUIRED

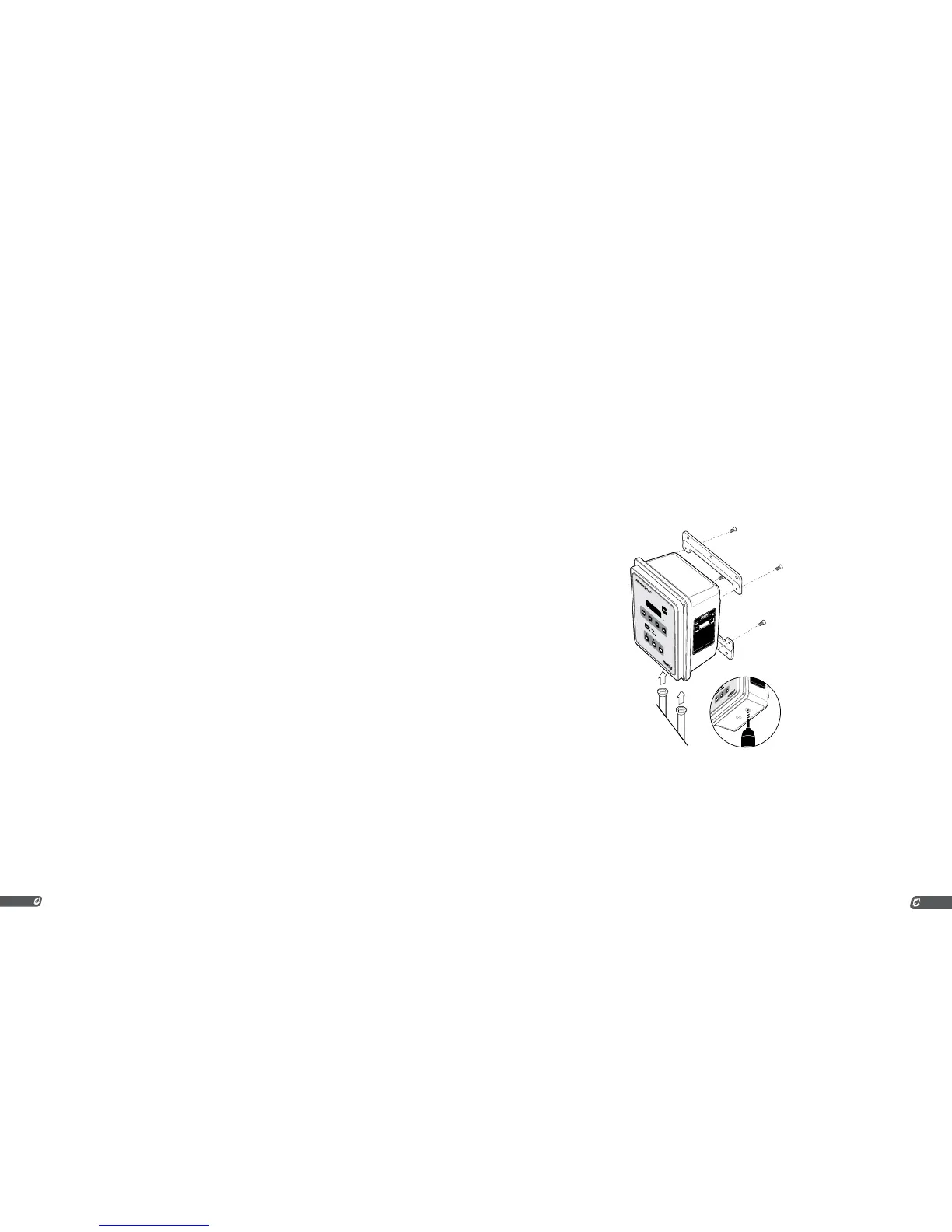

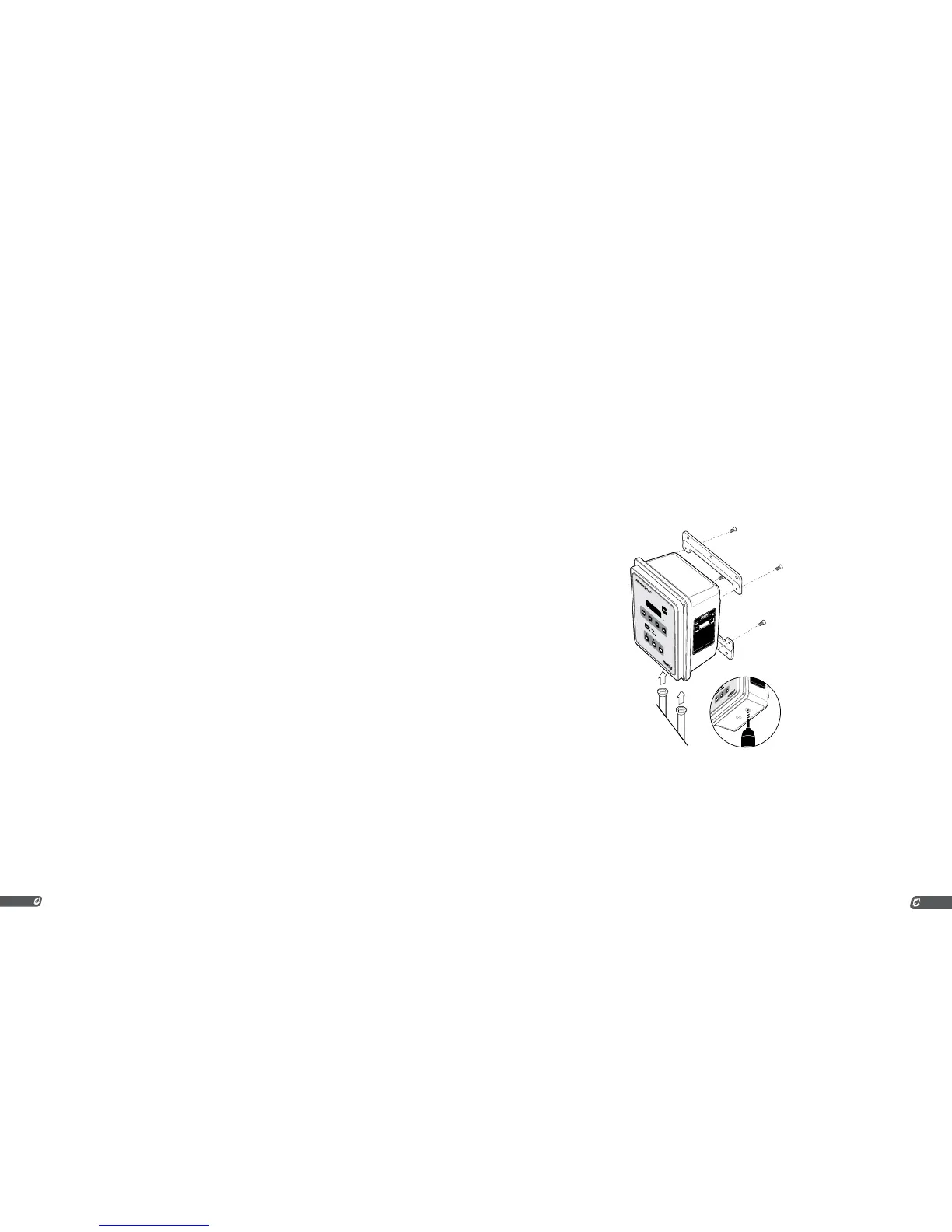

MOUNTING INSTRUCTIONS

1. Remove the included bag of components taped to the

mounting brackets.

2. Attach the two mounting brackets to the back of the PF2100

enclosure using the 4 provided screws.

3. Determine the best location to drill holes in the product

enclosure for the wires to enter. It is recommended that these

holes be drilled on the bottom of the enclosure (as shown).

4. Install grommets or conduit ports as required.

Loading...

Loading...