8584

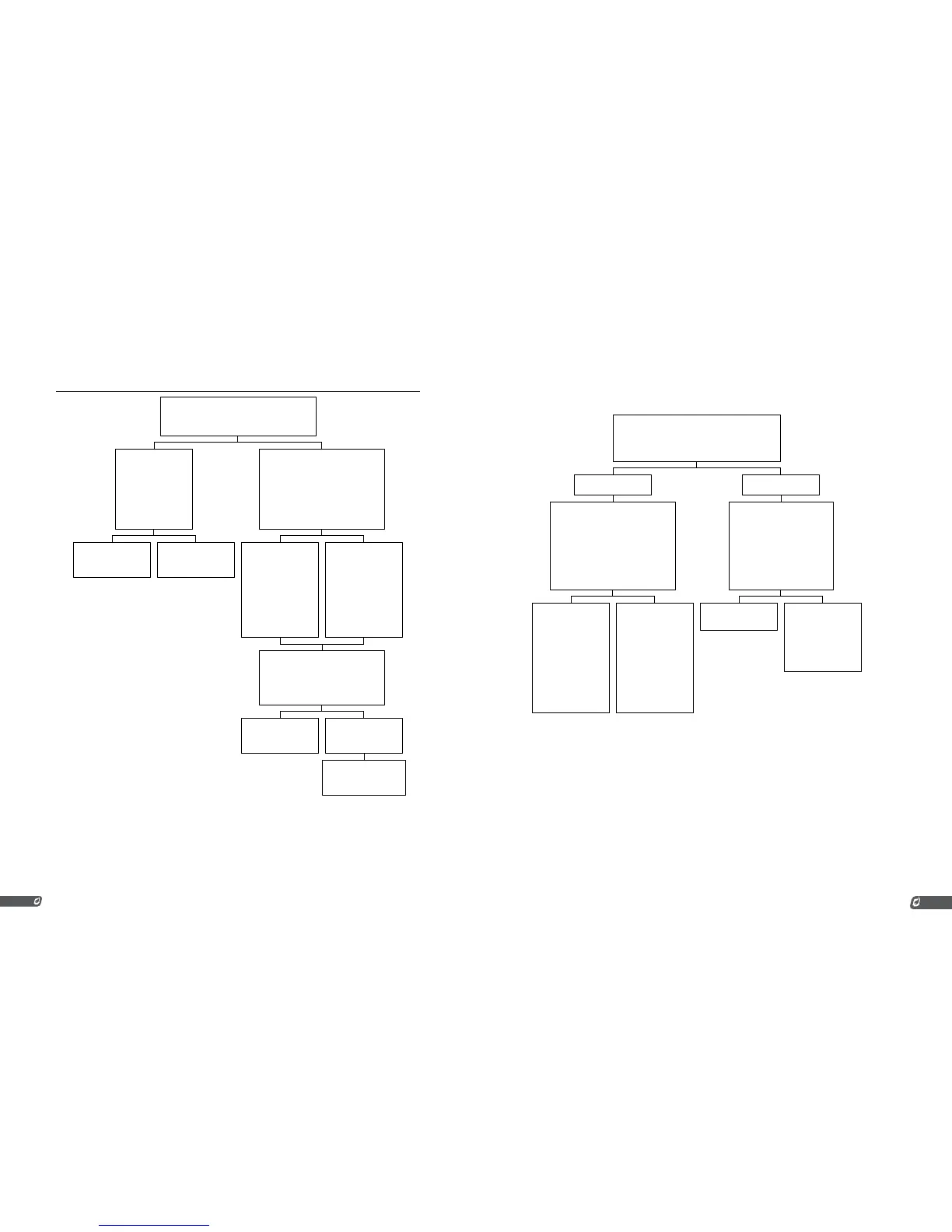

Flow Chart 2

Set the Multimeter to measure DC voltage across

ION + and ION - with the system in manual mode.

Is the reading across ION + and ION - around +5VDC?

Remove the wire from

ION + and measure

the DC voltage be-

tween the ION + and

ION - terminals again.

Is the voltage across the

ION + and ION - termi-

nals around +5VDC?

Put the system into Auto Mode and

monitor the voltage on the Multi-

meter. While sparking the voltage

will jump around; ignore this.

Take note of the voltage after the spark-

ing while the flame is still present.

Did the voltage drop below +5V when the

flame was present?

Check the ION + wire

for nicks or other faults.

It is possible that the

terminal card is faulty.

The system is not

seeing the flame at all.

The circuit from the rod

through the flame to

the nozzle to ground is

not being completed.

Check the grounding

to the pilot nozzle.

Check for cracked ce-

ramic on the flame rod.

The system is sensing

flame, just not enough.

The DC voltage should

drop to -5VDC or lower

(-8VDC is better for

stable flame detection.

Adjust the flame rod

positioning to try to de-

crease the voltage while

the flame is present.

The problem could be related to

flame anchoring. To verify this, place

a grounded rod in the flame.

Did placing the grounded rod in the flame

improve the DC voltage reading?

Recheck the orifice size

and increase the pilot

pressure.

Try replacing the pilot

nozzle.

Set the system up to use

separate rods for flame

detection and ignition.

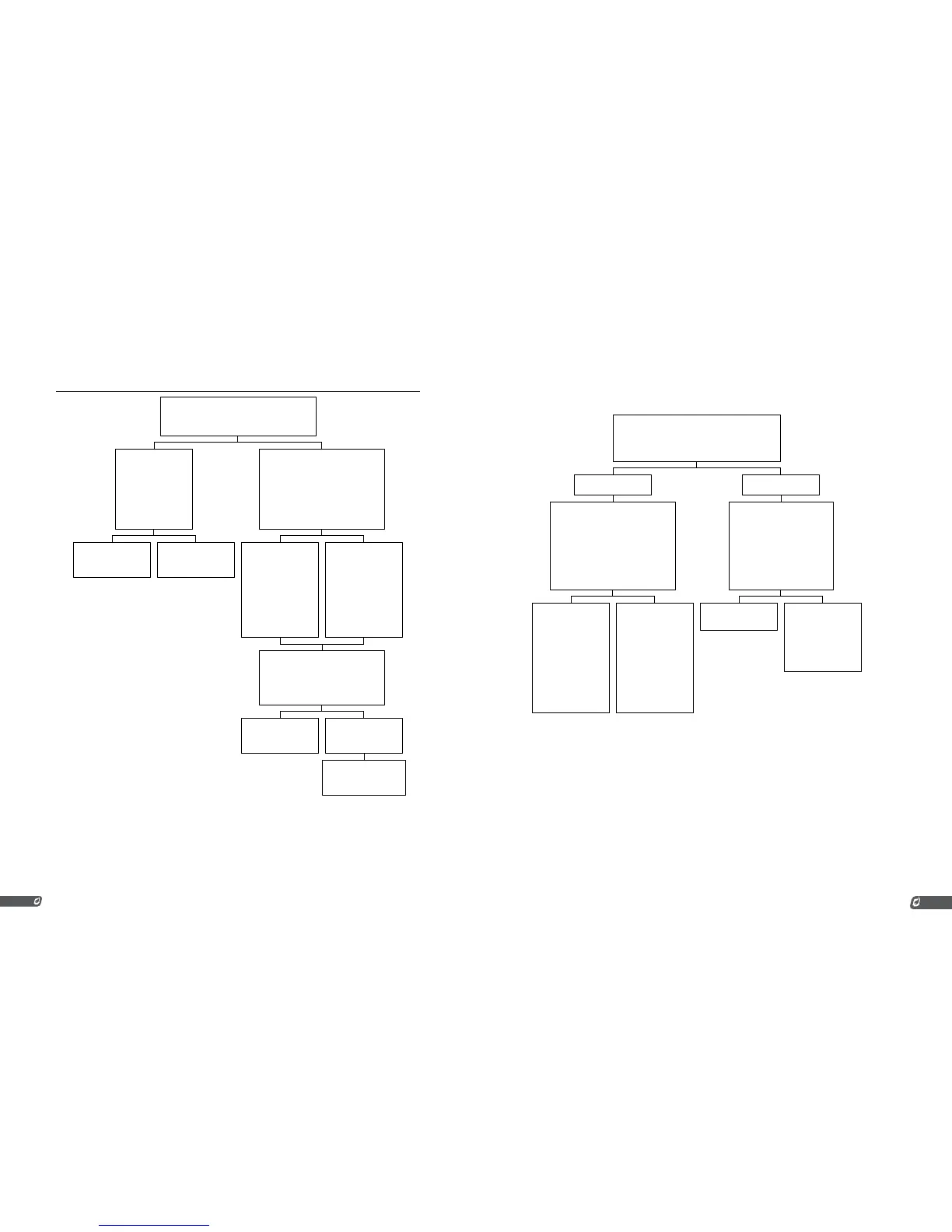

6.6 | Thermocouple Troubleshooting Guide

Problem with Thermocouples.

Make sure that both the High Temp and Pro-

cess thermocouples are connected.

Is the system reading Process TC, ProcTC, HH thermo-

couple or ProcHTC?

Ye s

No

Likely TC’s not equal or TC mismatch.

Set a Multimeter to read millivolts DC

(mVDC) and measure across High-

Temp_TC + and HighTemp_TC -.

Also measure across Process_TC -.

Are the voltages measured across the

two thermocouples within 0.1 mVDC?

Check the thermocouple wir-

ing and make sure that the

thermocouples are paired

correctly (not reversed).

The thermocouple indication

by the system may be faulty.

Install a jumper across Pro-

cess_TC + and Process_TC -.

Did the error clear?

The system is likely

reading correctly. Set the

meter to read conti-

nuity and check that

the thermocouples are

paired correctly and not

reversed. If the thermo-

couples are paired cor-

rectly and not reversed

it is possible that one

of the thermocouples is

faulty and will need to be

replaced.

The system is likely out

of calibration. Recali-

brate the HighTemp_TC

and Process_TC.

If the calibration did not

resolve the problem, it is

possible that one of the

circuit boards will need

to be replaced.

One of the circuit boards

may be faulty.

There is likely a problem

with the thermocou-

ple or the wiring.

Verify that there is con-

tinuity between the red

and yellow wires for each

thermocouple.

Loading...

Loading...