1312

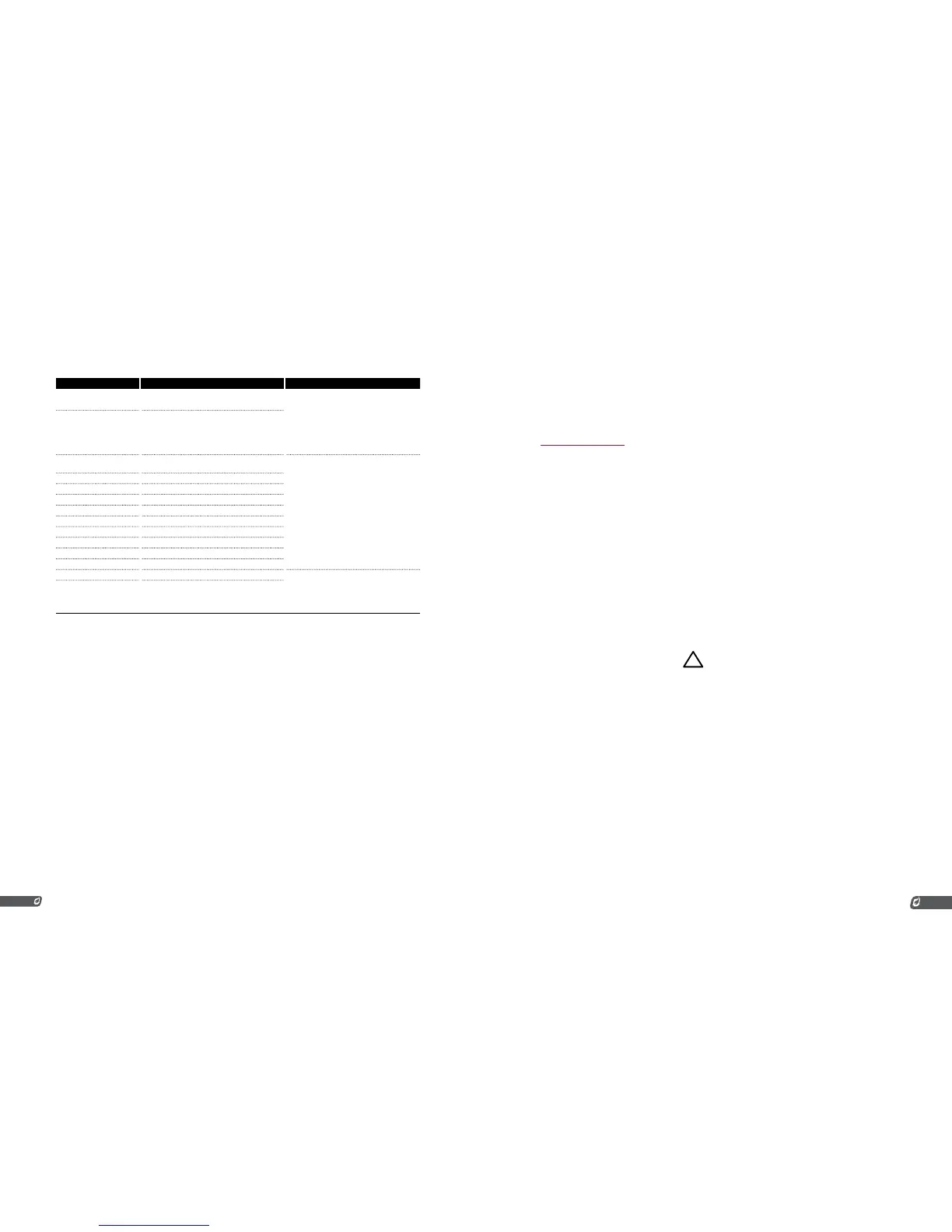

TERMINAL EXPECTED CONNECTIONS DESCRIPTION

Status + Connect to PLC positive input contact or other

alarm device.

The status “+” and “-” contacts will be closed

when the system is running and opened when

the system is shutdown. Dry contact output to

indicate system status to an external device.

ie. PLC. Note that the contacts are DC only

and are not internally connected to power or

ground.

40VDC, 250mA, 15Ω

Status - Connect to PLC negative input contact or other

alarm device.

Start + Remote start input from an external device. ie.

PLC.

Dry contact switch is expected. The input

is internally pulled up to 9VDC via a 3.75kΩ

resistance. Jumper “+” and “-” if not used.

All input contacts can use a single common

ground return if desired.

Start - Ground

ESD + External Shutdown input, typically plant ESD loop.

ESD - Ground

Proof of Closure + Proof of Closure from main valve(s).

Proof of Closure - Ground

High Pressure + Input from a mechanical High Pressure switch.

High Pressure - Ground

Low Pressure + Input from a mechanical Low Pressure switch.

Low Pressure - Ground

Level + Input from a float-switch mounted in the bath.

Dry contact switch is expected. The input

is internally pulled up to 9VDC via a 3.75kΩ

resistance. Jumper “+” and “-” if not used.

All input contacts can use a single common

ground return if desired.

Level - Ground

2 | INSTALLATION

The PF2100 can be used with many different systems. Before you begin installation, identify which

system the BMS will be used to control. In addition to this document, Profire has an Installation Guide

and several installation specific Whitepapers available describing common scenarios. These can be found

at www.profireenergy.com.

The steps provided here are general and can help you to identify questions that need to be answered to

complete the installation process. If you are new to the PF2100, you should read this whole section and

follow the instructions closely.

Steps

1. Review all installation warnings

2. Install the system

3. Connect the required wiring including Power, Valves,

Thermocouples, and Ignition Coil / Flame Detection wiring

4. Connect any additional wiring as required for your specific

application. Commonly used lines include the Status Contact,

Dry Contact Inputs, 4-20mA Temperature Output, and

Expansion Cards

To know which options are required, you should consult the engineer or technician who designed the

site. You should also be familiar with the local electrical and gas code for the site.

2.1 | Installation Warnings

!

Before installing the PF2100, please review the following list of warnings. Failure to consider these

warnings may result in death, electrocution, property damage, product damage, and/or government fines.

1. The PF2100 is not intended for use on burners greater than

12.5 MMBtuh. It is against code in many locations.

2. To use the PF2100 on burners greater than 5 MMBtuh, it is

recommended that the low fire feature with two safety shutoff

valves be used. At least one of these valves should use Proof

of Closure. This is required in many locations.

3. Failure to properly ground the pilot assembly back to the

PF2100’s Ion terminal may result in accidental electrocution,

product damage, or simply failure to ignite the pilot.

4. The PF2100 generates 20kV - 40kV at its high voltage output

terminal which can cause cardiac arrest. Do not touch or

place any object near the ignition coil’s high voltage terminal

or connected ignition wire while the product is operating.

Even without making physical contact with the terminal, it is

possible to draw a spark from several inches away, especially

if the pilot bracket is not properly grounded.

5. Never leave the PF2100 running unattended without the

door screws securely tightened down. This is to prevent

moisture from getting inside of the enclosure and damaging

Loading...

Loading...