5352

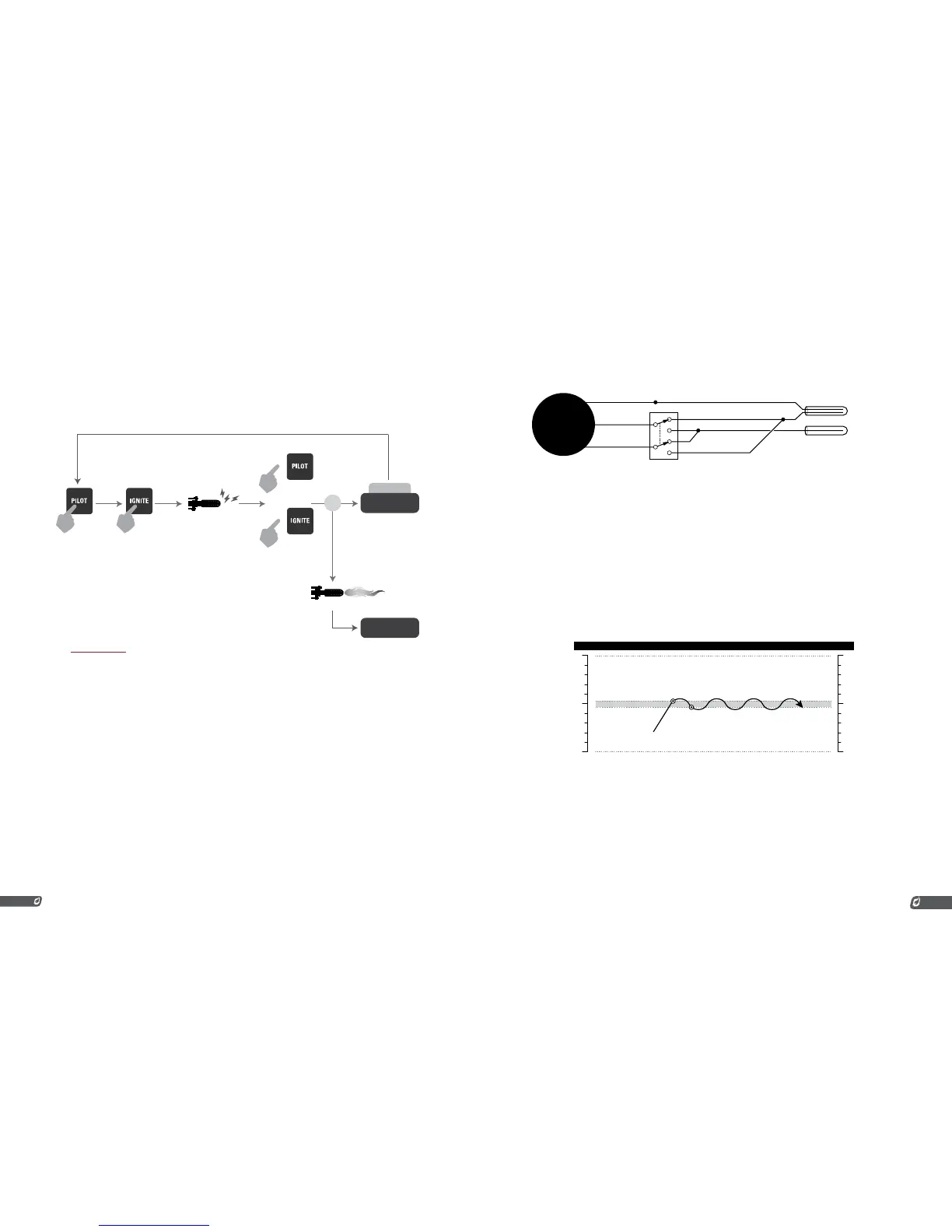

STARTING IN MANUAL MODE

When the system is started in Manual Mode (using the Pilot, Ignite, and Main Keys), it must be manually

moved through the ignition sequence. In Manual Mode, the PF2100 will NOT automatically attempt to

relight the pilot if it ever goes out unexpectedly. It will only attempt to relight the pilot if it was turned off

by the system as a result of normal process control (ie, Waiting on Temp, Waiting for Level, etc).

PRESS AND HOLD

RELEASE

FLAME DETECTED

SHUTDOWN

ERROR

FLAME

DETECT

PROCESS

CONTROL STARTS

+

The Process Control sequence will be explained in more detail later.

4.2 | Process Control

The PF2100 maintains a process at a user specified temperature. The system monitors the temperature

and adjusts to increase or decrease the temperature as needed. This is an automated sequence of events

based on user settings. This process of monitoring and controlling is called Process Control. The system

uses a gas fired heater with an electronic ignition circuit and several electronic fuel valves (also called

solenoids). It also has a flame detection circuit and up to three temperature measuring thermocouples.

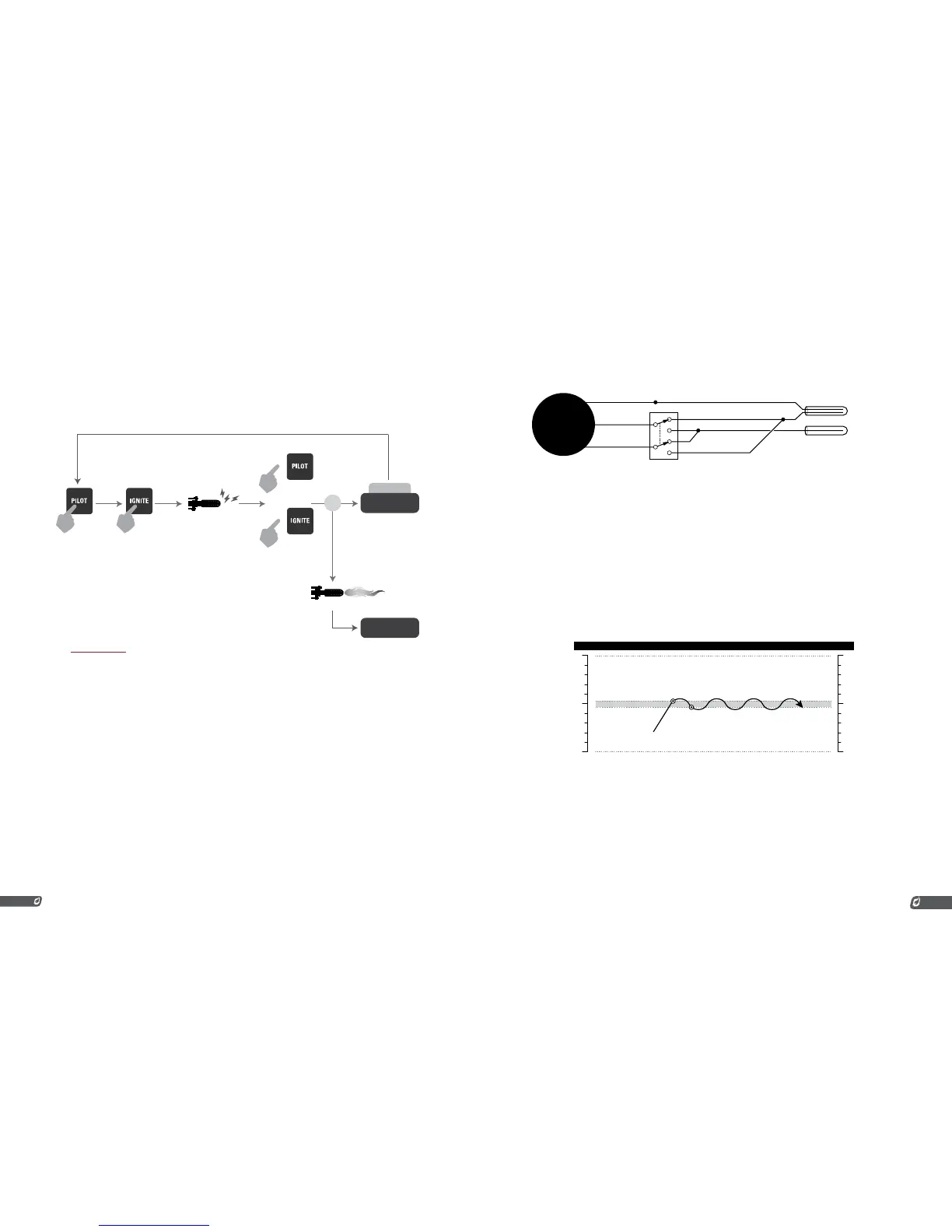

The PF2100 has three inputs: High Temp, Proc Temp, and Aux Temp. By default, these signals correspond

to the High Temp Thermocouple, the Process Thermocouple, and the Aux Thermocouple respectively.

The Process Control setting allows the Process and Aux thermocouples to be swapped. This is useful in

circumstances that will be explained later.

HIGH TEMP HIGH TEMP THERMOCOUPLE

THERMOWELL #1

THERMOWELL #2

PROCESS THERMOCOUPLE

AUX THERMOCOUPLE

PROC TEMP

AUX TEMP

“PROCESS CONTROL” SETTING

Internal Software Signals External Physical Connections

It is expected that the High Temp Thermocouple and the Process Thermocouple will always be mounted

in a common thermowell. This is usually accomplished by using a duel element thermocouple. The

software uses these two thermocouples as a check for each other as a failsafe. If the readings from

these two thermocouples do not agree within a specified amount of error, the system will shut down.

The High Temp signal is used to protect the burner and other process equipment from being damaged

due to excessive heat. It cannot be disabled through any combination of process control settings.

The Proc Temp signal is the primary control signal for Process Control. This signal is compared to the

Deadband, Low Temp Alarm Setpoint, Process Setpoint, Low Fire Setpoint, and the Pilot Off Setpoints in

order to control the temperature of the process.

The Aux Temp signal can be used as a secondary control signal. The way that this signal is used will vary

depending on the Aux Temp Mode setting. If enabled, an Aux Setpoint gets compared to this signal.

STANDARD PROCESS CONTROL

Using very basic settings, the PF2100 behaves as follows.

DEAD BAND

TEMP EXCEEDS

SETPOINT

PROCESS

TEMPERATURE

TEMP DROPS

BELOW SETPOINT

TIME˚C ˚F

MAIN ON

MAIN OFF

1. The Main Valve opens and the Process Temperature increases.

2. The Process Temperature exceeds Process Setpoint, the Main

Valve closes, and the Process Temperature begins to drop.

3. The Process Temperature drops below the Process Setpoint

minus Deadband, the Main Valve opens, and the Process

Temperature begins to increase again.

LOW FIRE: ON AT PROC SETPOINT

This example has the Process (High Fire) and Low Fire Setpoints enabled. It has been set to turn on at

the Process Setpoint. This example uses two valves, a Low Fire valve and a High Fire valve. Both valves

start open in this example.

Loading...

Loading...