5554

The system behaves the same as in the standard process control diagram until the demand for heat

drops.

1. The Process Temperature reaches the Process Setpoint and

the main valve closes.

2. The Process Temperature continues to rise.

3. The Process Temperature exceeds the Low Fire Setpoint, the

Low Fire Valve closes, and the Process Temperature drops.

4. The Process Temperature drops below the Process Setpoint

minus the Deadband, the High Fire Valve opens, and the

Process Temperature begins to increase again.

PROPORTIONAL VALVE CONTROL

The Low Fire: On Proc Setpoint can be used in conjunction with a proportional valve connected to the

4-20mA Output. In this mode, the PID Controller adjusts the proportional valve and attempts to fix the

temperature at the Process Setpoint.

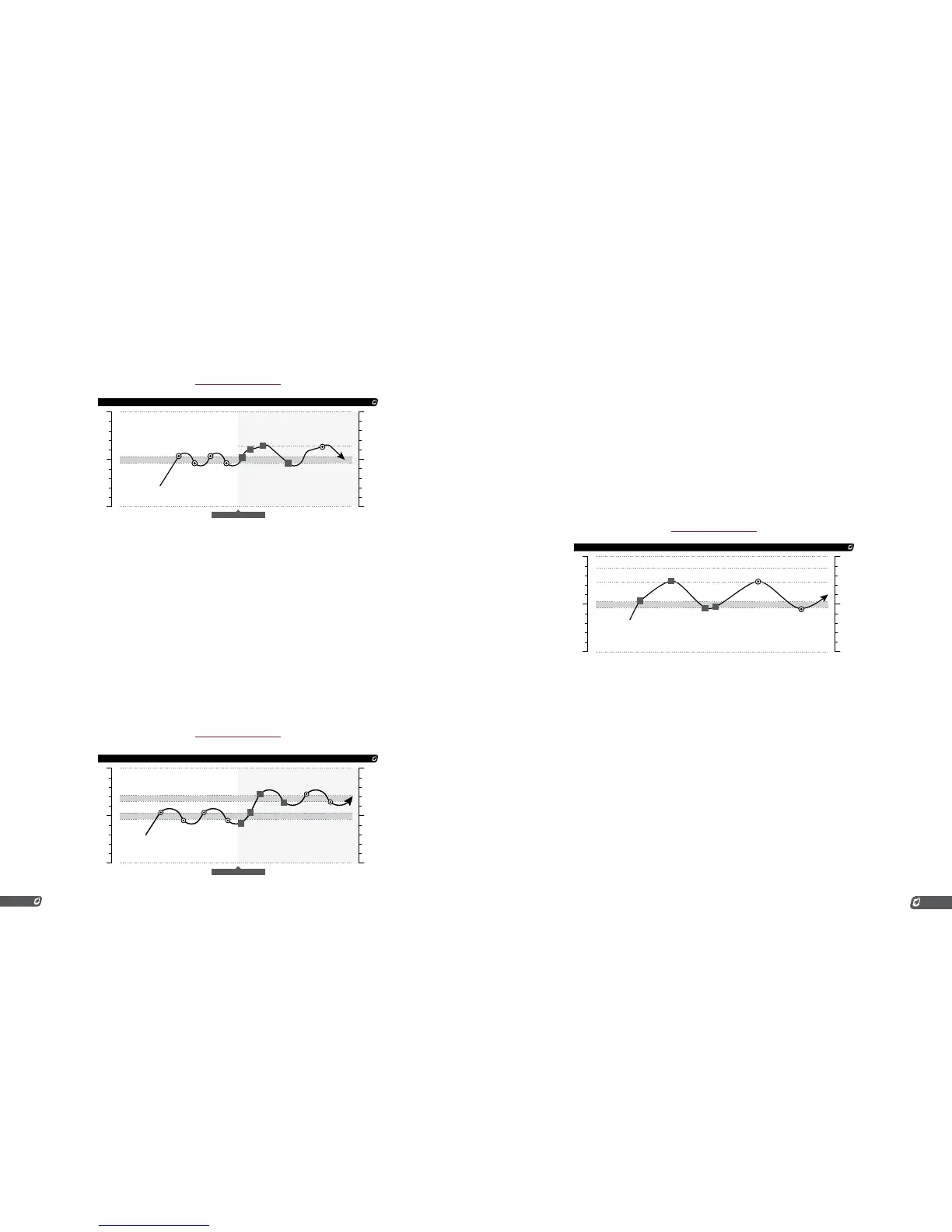

LOW FIRE: ON AT LOW FIRE SETPOINT

This example has the Low Fire feature enabled and set to “On at Low Fire Setpoint.” In this case, the Low

Fire Valve will close when it exceeds the Low Fire Setpoint, and will reopen after it drops below the Low

Fire Setpoint minus Deadband.

The system behaves the same as in the standard process control diagram until the demand for heat

drops.

TEMP DROPS BELOW

LOW FIRE SETPOINT

MINUS DEADBAND

122

TIME˚C ˚F

LOW FIRE SETPOINT

HIGH FIRE SETPOINT

DROPPED HEAT DEMAND

4

3

2

1

1. The Process Temperature continues to rise.

2. The Process Temperature exceeds the High Fire Setpoint, the

High Fire Valve closes, and the Process Temperature continues

to rise.

3. The Process Temperature exceeds the Low Fire Setpoint, the

Low Fire Valve closes, and the Process Temperature drops.

4. The Process Temperature drops below the Low Fire Setpoint

minus Deadband, the Low Fire Valve opens, and the Process

Temperature begins to rise again.

PILOT OFF

This scenario is the same as the basic scenario except that the Pilot Off feature has now been enabled.

In this case, when the Proc Temp rises above the Pilot Off Setpoint the Pilot Valve will close and will not

re-light until the temperature is below the Process Setpoint minus Deadband.

The system behaves the same as in the standard process control diagram with the added ability to shut

off the pilot as needed.

1. The temperature exceeds the Proc Setpoint and the Main

Valve closes.

2. The temperature continues to rise and the Proc Temp exceeds

the Pilot Off Setpoint, the Pilot Valve closes, and the Proc

Temp begins to decrease.

3. The Proc Temp drops below the Process Setpoint minus

Deadband, the pilot relights, and the Proc Temp begins to

increase again.

4. The Pilot-to-Main Delay elapses, the Main Valve opens, and

the Proc Temp begins to increase faster.

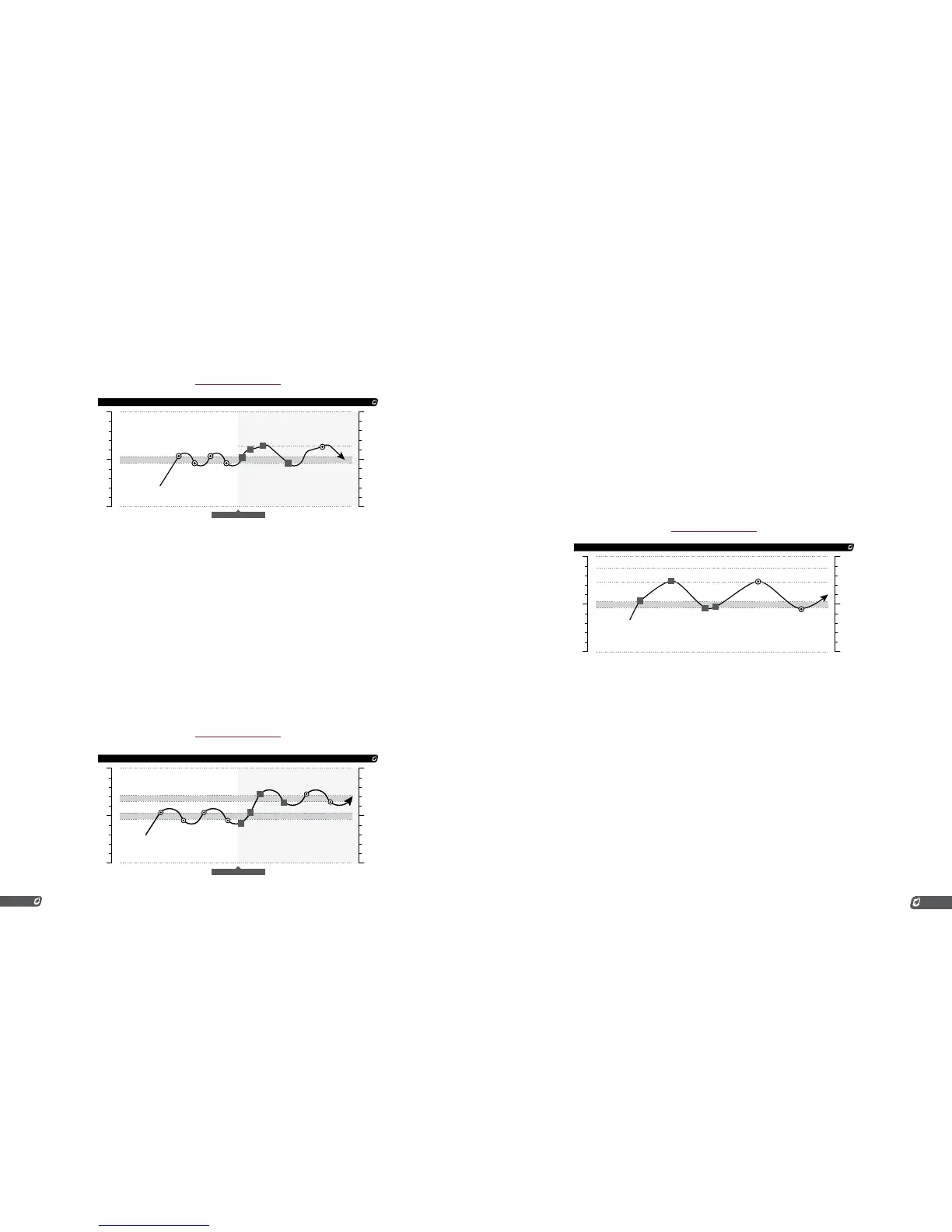

HIGH TEMP ESD

The High Temp ESD Setpoint is always compared against the High Temp Thermocouple regardless of

the Process Control setting. The system will immediately shut down if this thermocouple exceeds this

setpoint. Because the High Temp Thermocouple and Process Thermocouple must always be in the same

thermowell, these two thermocouples can be thought of as being the same. Note that the internal signal

to which the Process Thermocouple is associated (Proc Temp or Aux Temp) will change depending on the

Process Control setting.

This particular graph is a representation of a high temperature shutdown. Once the Process Temperature

exceeds the High Temp ESD Setpoint, the system will shut down and require user input to acknowledge

the error.

Loading...

Loading...