ALARM

(NO

CONTACT)

OPEN

CLOSED

OPEN

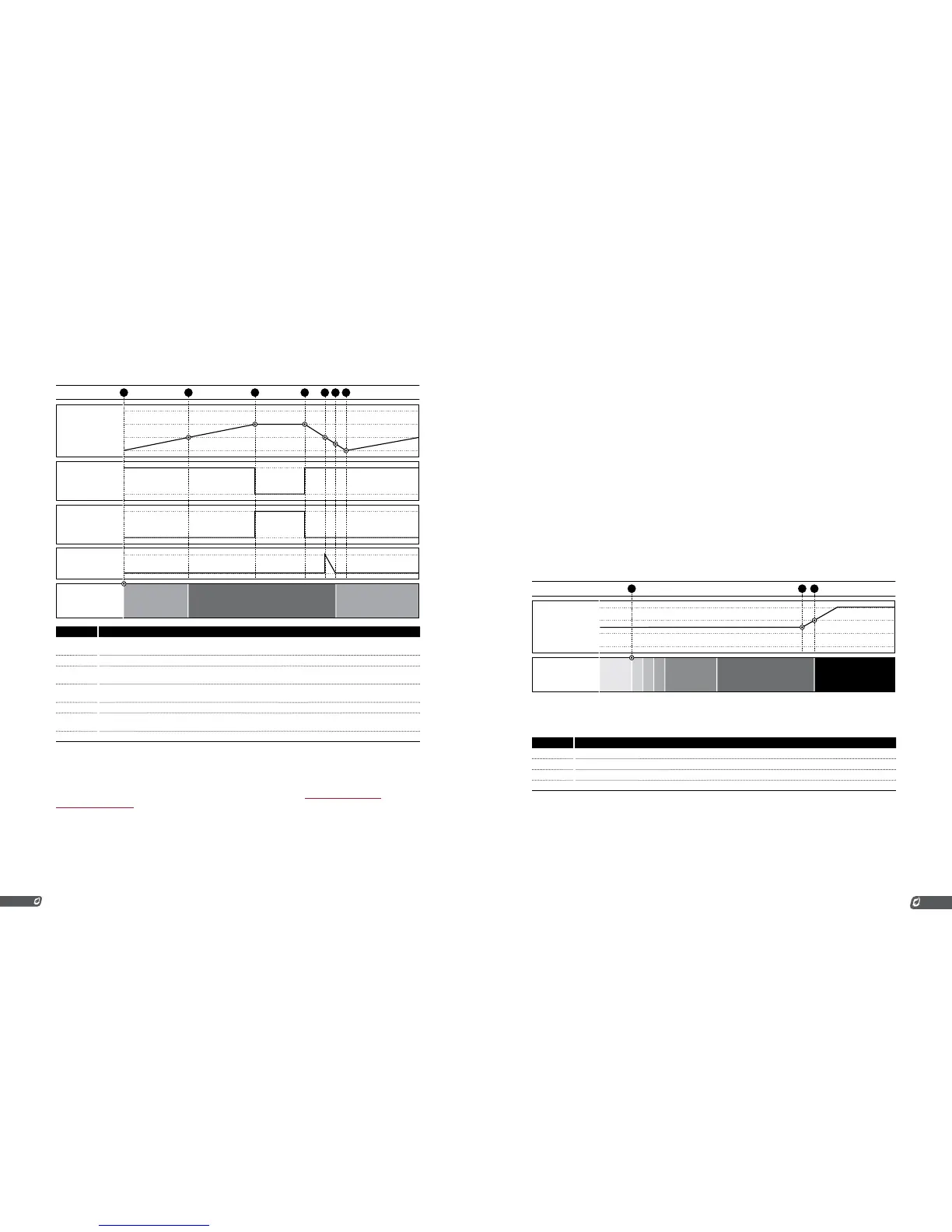

2 4 5 6

7

31

# CHART 1 EVENTS

1 System started with tank empty. Pump starts filling tank. Burner is off and system is waiting on level input

because 4-20mA level input is below the low setpoint.

2 Tank level rises above low setpoint. System begins running (heating tank).

3 Tank level rises above the high setpoint, the pump turns off and the remote alarm turns on to signal a truck to

come and empty the tank.

4 An operator arrives on site and begins emptying the tank into a tanker truck. The pump turns back on and the

alarm turns off.

5 The tank level drops below the low setpoint and the level delay timer begins counting down.

6 The level delay timer reaches zero after 2 or 20s (depending on the “Pressure/Level Delay” setting) and the

system stops heating the tank and returns to the “Waiting on Level” state.

7 The tank is empty and the tanker truck leaves the site. The tank level begins rising again.

4-20MA PRESSURE INPUT

The 4-20 Pressure Input is used to monitor fuel train pressure in the same way as the Pressure Contacts.

The behavior and features are similar to those described in the previous Low Pressure Contact and

High Pressure Contact sections. One difference is that a Pressure Transmitter is used instead of a pair

of Pressure Switches and the setpoints are set via a menu instead of mechanically on the switches.

When the 4-20 signal is below the low setpoint or above the high setpoint, the system will stop. When

it is between the two setpoints, it will run. The system can be started when the input signal is above the

high pressure setpoint. This is to allow for easy recovery from the common issue of leaky regulators.

If the regulator upstream from the high pressure switch is leaky, it can allow pressure to accumulate

at the switch’s position over time while the system is not running. Since there is no way to relieve this

pressure other than to open a downstream valve, the system must be allowed to start running under this

condition. The system will start, light the pilot, and open the main valve to allow the built-up pressure to

be relieved. If the pressure does not drop below the high pressure setpoint within 2 seconds after the

main valve has been opened, the system will shutdown. Otherwise it will continue running. This behavior

is depicted in charts 2 and 3 below. The system can be setup to restart from a low pressure event but not

from a high pressure event.

To use the 4-20 Pressure Input, it must be setup as follows:

1. Attach a properly calibrated Pressure Transmitter to the 4-20

Pressure Input

2. Enable the Pressure DIP Switch on the 4-20 Card

3. Enable the 4-20 Card in menu 6

4. Set the Pressure Low Setpoint, High Setpoint, Range, and

Units in menu 6

5. Disable the Low Pressure and High Pressure Contacts by

installing a jumper in each of them

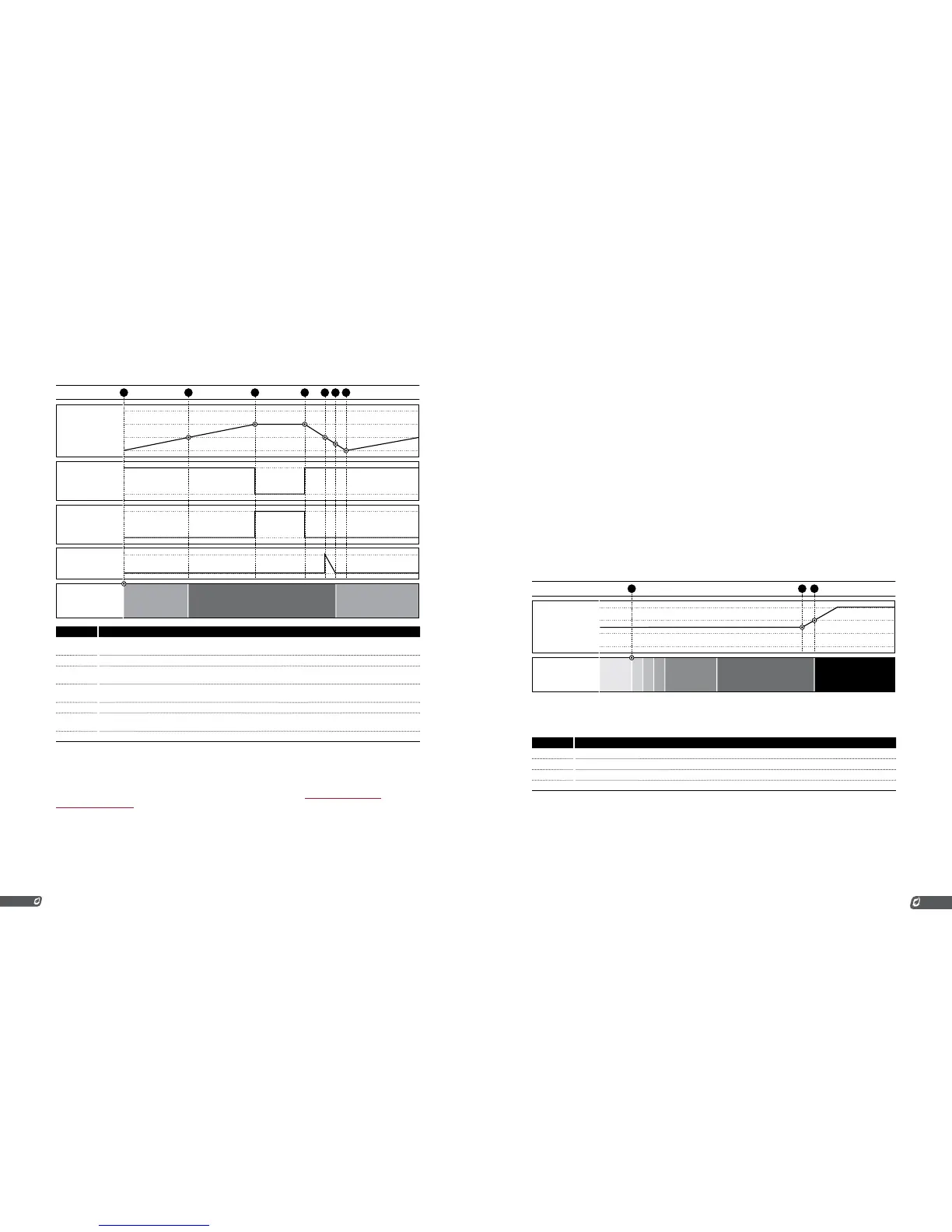

Chart 1: Pressure Increases While Running

SYSTEM

STATE

READY

PURGE

IGNITE

FLAME

MAINPILOT DELAY SHUTDOWN

4-20 PRESSURE

20mA

4mA

EVENT

2 31

Loading...

Loading...