9 Maintenance

WARNING!

It

is mandatory that you read the safety information and

specifications in the "Storage, Transport and

Unpacking" chapter prior to shipping the pump.

CAUTION!

Warning of feed chemical spraying around

Feed chemical can spray out of the hydraulic compo‐

nents if they are manipulated or opened due to pressure

in the liquid end and adjacent parts of the system.

– Depressurise the system prior to undertaking any

maintenance or repair work!

Interval Maintenance task Personnel

Quarterly* n Check the diaphragm for damage

- refer to "Repair"

n Check the leakage hole for escaping feed chemical

n Check that the dosing lines are fixed firmly to the liquid end

n Check that the suction valve and discharge valve are tight

n Check the tightness of the entire liquid end - particularly around the

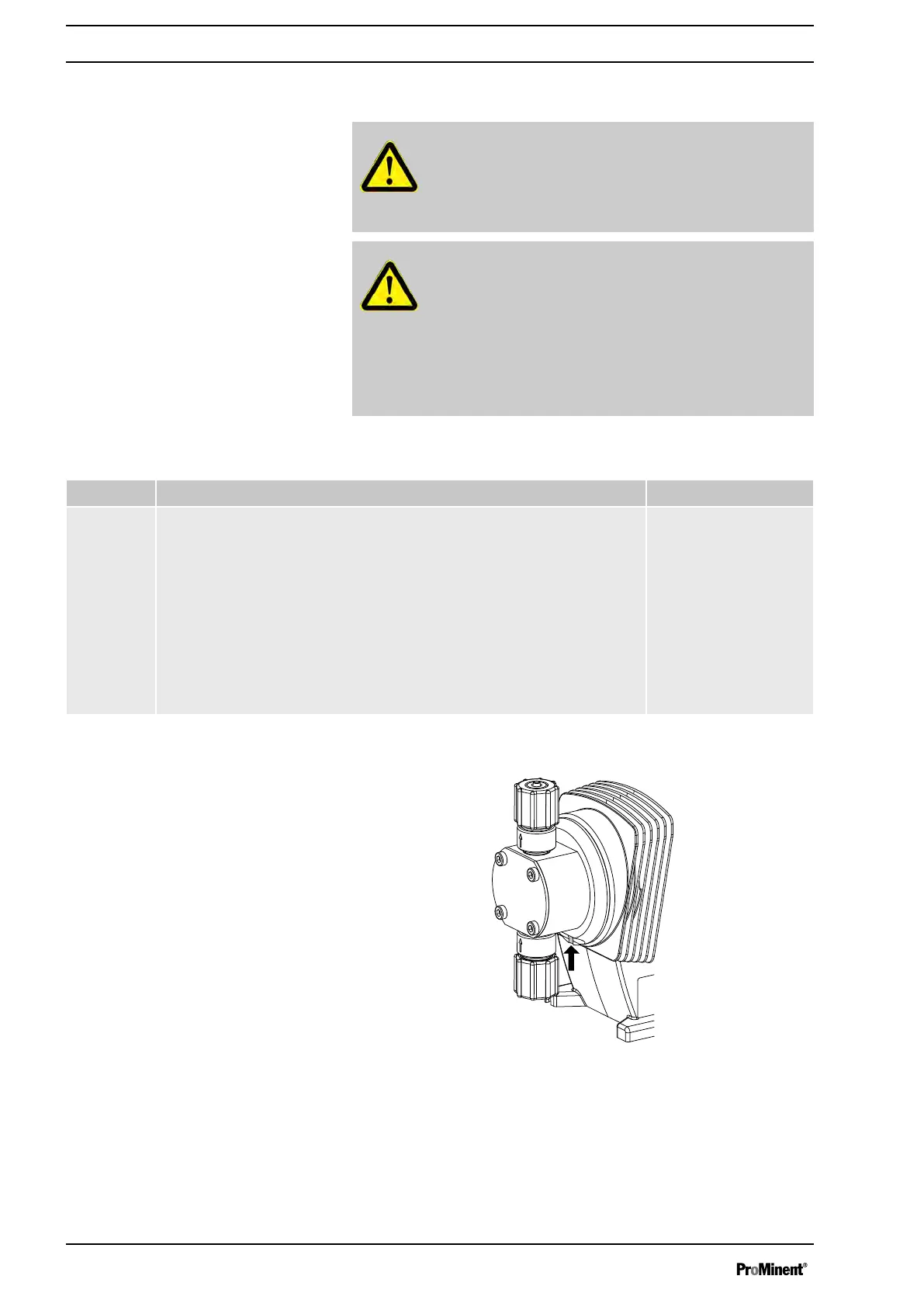

leakage hole Fig.

11!

n Check that the flow is correct: Allow the pump to prime briefly - turn

the multifunctional switch briefly to "Test"

n Check that the electrical connections are intact

n Check that the dosing head screws are tight

Technical personnel

* under normal loading (approx. 30 % of continuous operation)

Under heavy loading

(e.g. continuous operation): Shorter intervals.

Fig. 11: Leakage hole

Standard liquid ends:

Maintenance

28

Loading...

Loading...