CAUTION!

Danger due to incorrect use of the integral relief valve

The integral relief valve can only protect the motor and

the gear, and then only against impermissible positive

pressure that is caused by the metering pump itself. It

cannot protect the system against positive pressure.

– Protect the motor and gear of the system against

positive pressure using other mechanisms.

–

Protect the system against illegal positive pressure

using other mechanisms.

CAUTION!

Warning of feed chemical spraying around

If no overflow line is connected to the integral relief valve

or the integral bleeder valve, feed chemical will spray out

of the hose connector as soon as the relief valve opens.

– Always connect an overflow line to the integral relief

valve or the integral bleeder valve and feed it back

into the storage tank or - if required by the regula‐

tions - into a special storage tank.

CAUTION!

Danger of cracking

Cracking of the PVT liquid end can occur if a metal over‐

flow line is connected to the relief valve.

– Never connect a metal overflow line to the relief

valve.

CAUTION!

Danger of the integral relief valve failing

The integral relief valve no longer operates reliably with

feed chemicals having a viscosity of greater than 200

mPa s.

– Only use the integral relief valve with feed chemicals

having a viscosity up to 200 mPa s.

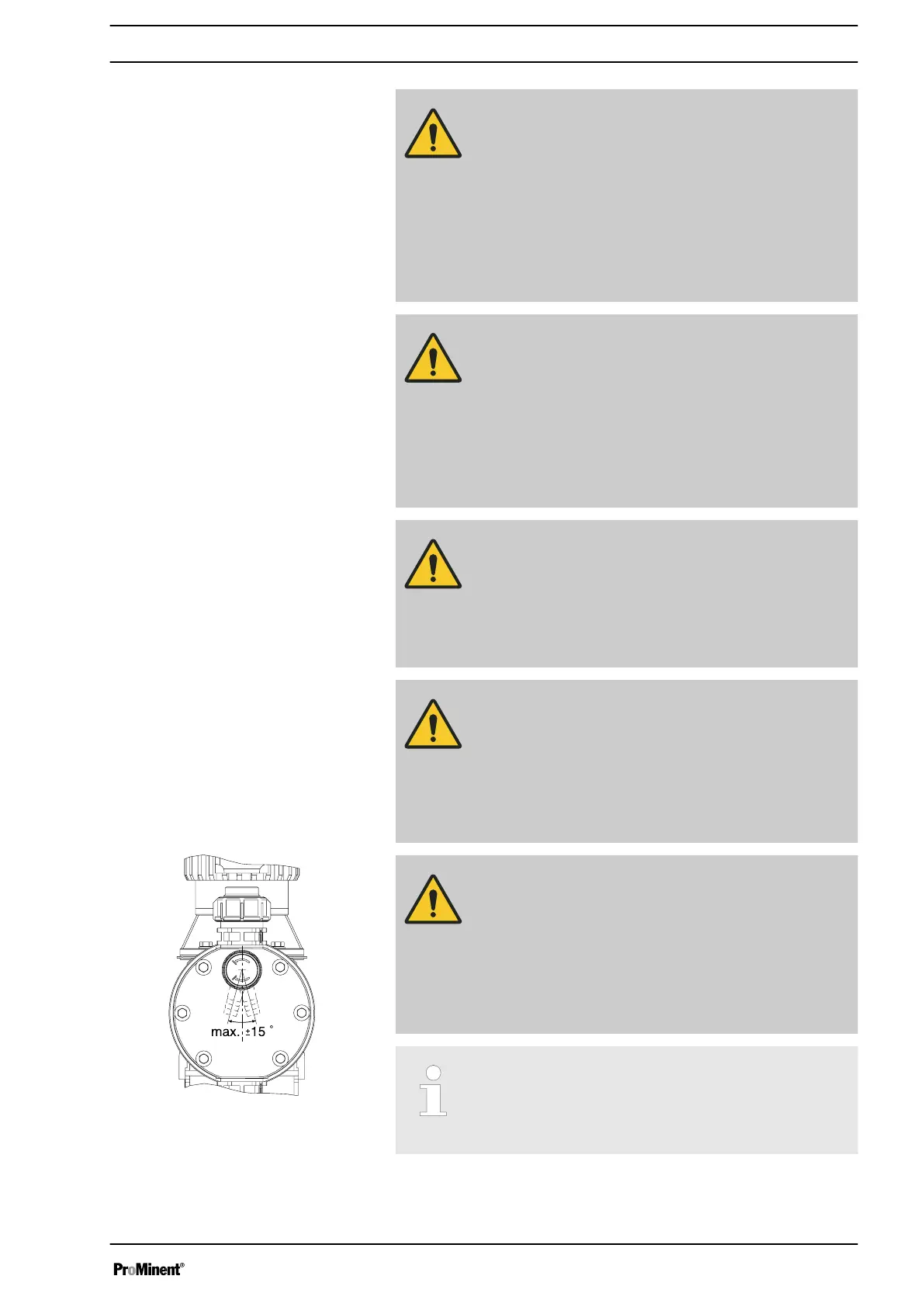

CAUTION!

Warning against leaks

Feed chemical, which remains in the overflow line at the

relief valve or bleeder valve, can attack the valve or

cause it to leak

– Route the overflow line with a continuous slope and

moreover with the tube nozzle pointed downwards -

see .

If the overflow line is fed into the suction line, the bleed

function is blocked.

Therefore lead the overflow line back into the storage

tank.

Fig. 18: Permissible alignment of the relief

valve

Installation

29

Loading...

Loading...