Handling

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 32 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

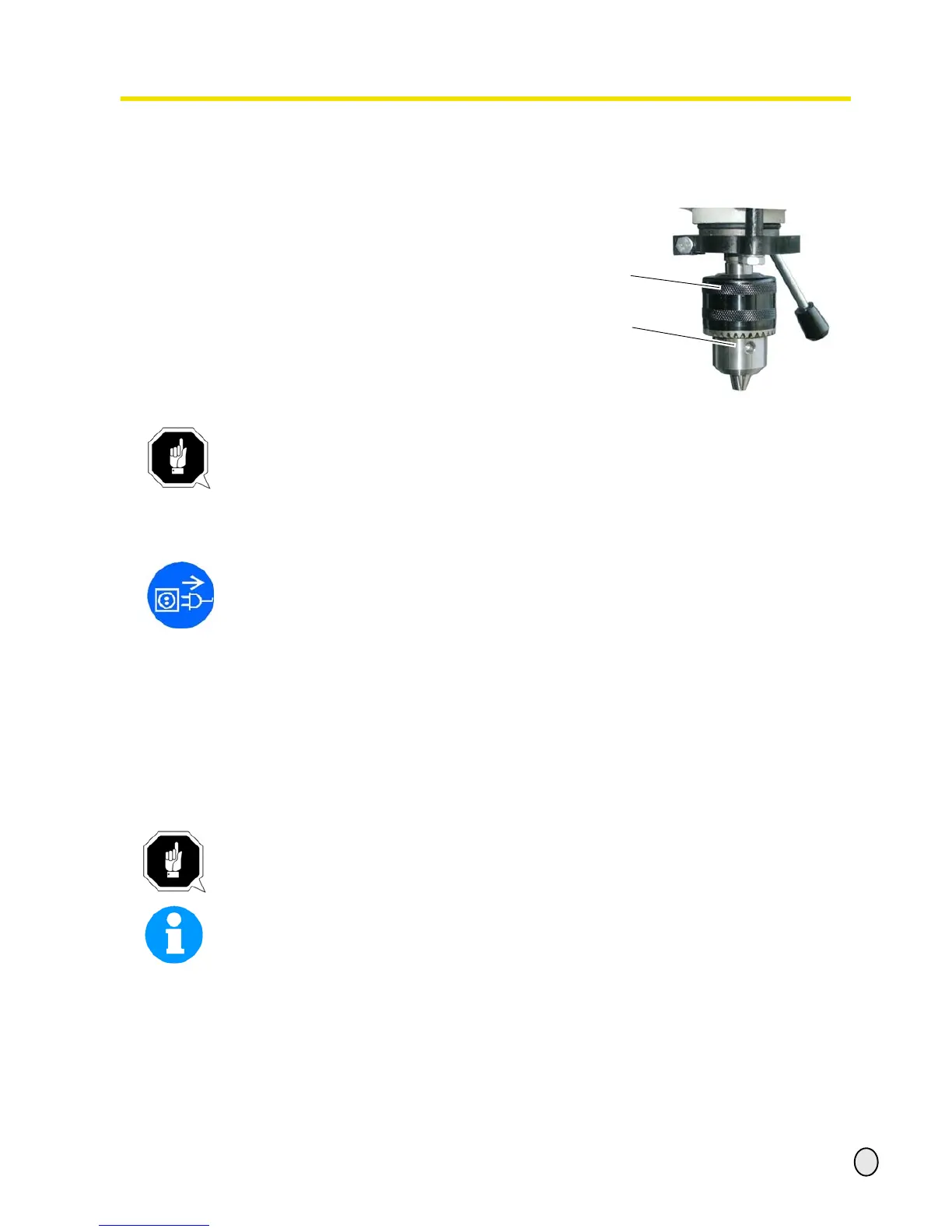

4.5 Drill chuck

4.5.1 Gear rim-drill chuck

Open the drill chuck by means of the key

for chucks.

Illustr.4-12: gear rim-drill chuck

ATTENTION!

Make sure that the chucked tool is positioned firmly and correctly.

4.5.2 Disassembly of the drill chuck

WARNING!

Disassemble the drill chuck only when the drilling machine is disconnected from the

electrical power supply.

Disconnect the drilling machine from the electrical power supply.

The conical connection can be separated with a plastic or a rubber hammer.

4.6 Cooling

The friction generated during rotation can cause the edge of the tool to become very hot.

The tool should be cooled during the drilling process. Cooling the tool with a suitable cooling

lubricant ensures better working results and a longer edge life of the tools.

This is best realized by a separate cooling equipment. If there is no cooling equipment included

in the delivery volume, you can cool by means of a spray gun or a washing bottle.

ATTENTION!

Danger of injury due to brushes getting caught or pulled in.

Use a spray gun or a washing bottle for cooling.

INFORMATION

Use a water-soluble and non-polluant drilling emulsion which can be obtained from authorized

distributors.

Make sure that the cooling agent is being collected.

Respect the environment when disposing any lubricants and cooling agents.

Follow the manufacturer’s disposal instructions.

4.7 Before starting the working process

Before you start working, select the required speed. It is depending on the drilling diameter and

on the material used.

upper part

gear rim drill chuck

opening for the

key for chucks

Loading...

Loading...