Malfunctions

quantum

MASCHINEN - GERMANY

© 2007

GB

Page 54 Drilling machine B 13 / B14 / B16 / B20 / B25 / B32 Version 1.2.5 18 / 01 / 2008

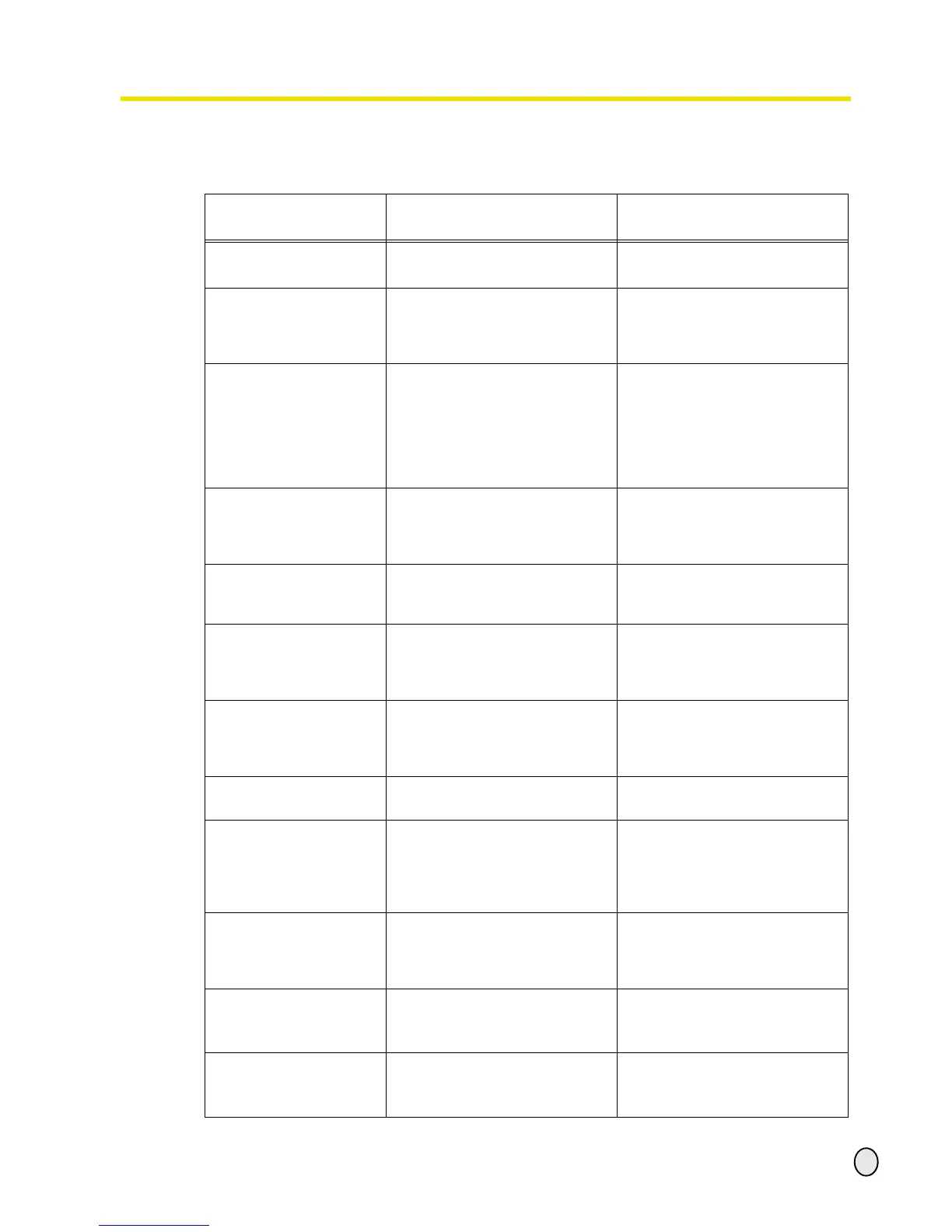

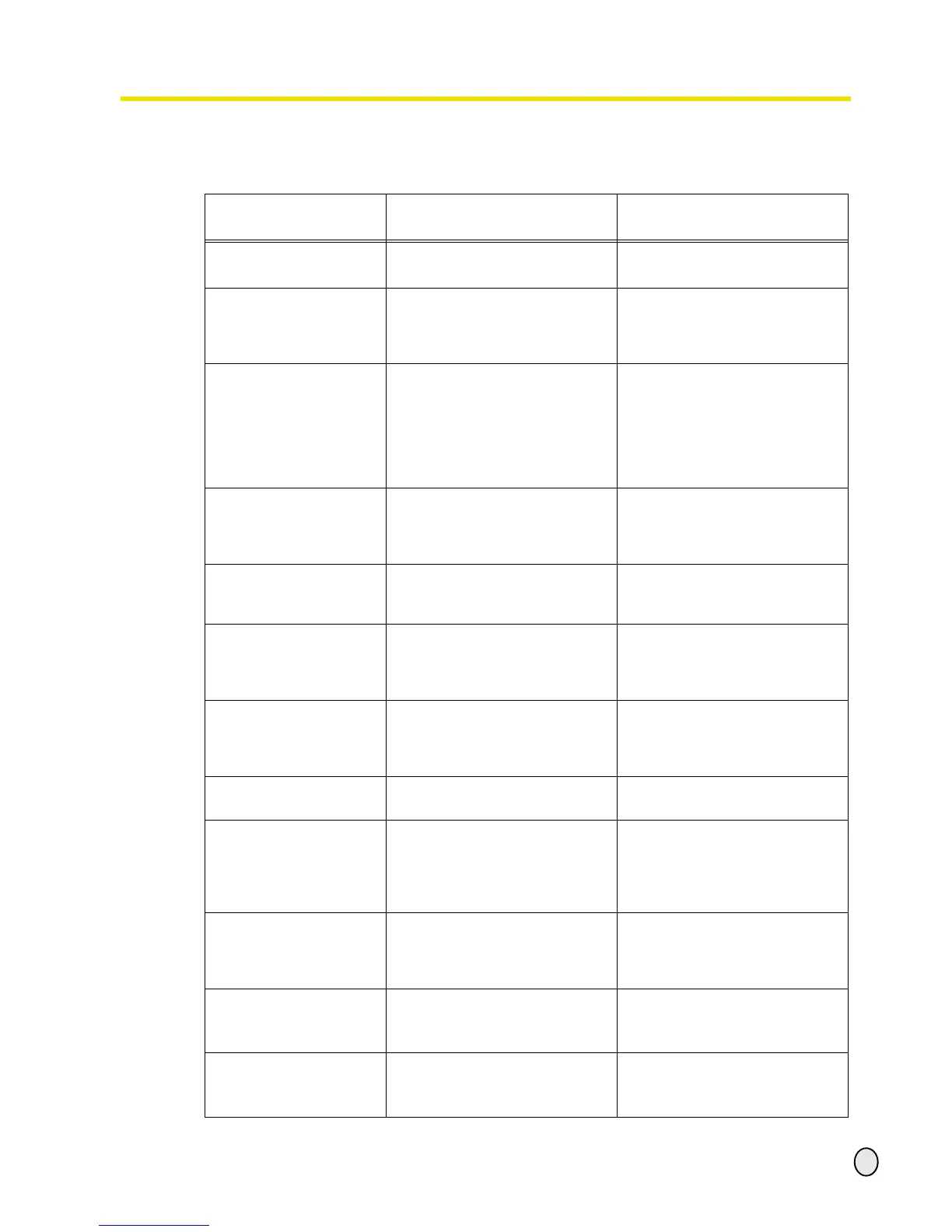

7 Malfunctions

Malfunction

Cause/

possible effects

Solution

FI protective switch dis-

engages

• a non-common FI protective

switch is used

• „Power supply“ on page 21

Noise during working

• Spindle turning dry.

• Tool blunt or is being incorrectly

secured.

• Grease spindle

• Use new tool and check secur-

ing (fixed setting of the bit, drill

chuck and morse taper).

Bit "burnt"

• Incorrect speed/ feed too fast

• The chips have not been

removed from the bore hole

•Bit blunt

• Operating without or too little

cooling agent

• Select another speed

• Extract the bit more often

• Sharpen or replace bit

• Use coolant

Bit tip moves, bore hole

is not circular

• Hard fibre in the workpiece

• unequal length of the cutting spi-

ral or unequal angles in the bit.

• Bit deformed

• Replace bit or re-sharpen it

Defective bit

• No support used • Place a wooden board beneath

the workpiece and secure them

to one another

Bit running off-centre or

„hopping“

• Bit deformed

• Bearings worn down

• Bit badly secured

• Drill chuck defective

• Replace bit

• Have the bearings replaced

• Secure the bit properly

• Replace the drill chuck

Impossible to introduce

drill chuck or morse taper

• There is dirt, grease or oil on the

inner conical surface of the drill

chuck or on the conical surface of

the drilling spindle

• Clean surfaces well

• Keep surfaces free of grease

Engine does not start

• engine connected wrongly

• Defective fuse

• Have it checked by authorized

personnel

Overheating of motor and

lack of power

• Engine overloaded

• Insufficient mains voltage

• Engine connected wrongly

• Disconnect immediately and

have it checked by authorized

personnel

• Have it checked by authorized

personnel

Precision of the work

deficient

• Heavy and unbalanced or twisted

workpiece

• Inexact horizontal position of the

workpiece holder

• Balance workpiece statically and

secure it without straining

• Adjust workpiece holder

Drilling spindle sleeve

does not return to its ini-

tial position

• Spindle restoring spring does not

work properly

• locking pin is being introduced

• Check spindle restoring spring,

replace it, if necessary

• pull out locking pin

The drilling sleeve may

not be moved down-

wards.

• The locking pin is introduced

• The drill depth setting is not

released

• Pull out the locking pin

• Release the drill depth setting

Loading...

Loading...